Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

After a year of testing to gain experience, EVCO is ready to begin production with its first LSR press for programs in medical and lighting. (Photos: EVCO Plastics)

EVCO Plastics doesn’t seem to have a first gear. Since 1964, the family-owned custom injection molder has launched a major expansion on average every three years, right through recession and pandemic, and has accelerated that pace of late. In recent years, EVCO also has expanded its technological base with the addition of 3D printing, collaborative robots, iMFLUX low-pressure molding, an automated UV-curing paint line, expanded process monitoring, white-room molding and liquid silicone rubber (LSR). In a recent interview with Plastics Technology, EVCO executives and engineers provided an update on the latest capacity expansions and technological initiatives in three main areas: automation, LSR and 3D printing.

More People, Plants & Machines

As the coronavirus pandemic eased its grip on the global economy, EVCO was ready with freshly added capacity at several locations. It purchased around 20 injection machines in 2021. At the start of 2022, the company moved its corporate headquarters in DeForest, Wis., to its MED (medical and electronics) facility, another of the three EVCO facilities there, which has remodeled its office space with an addition of 8000 ft2.

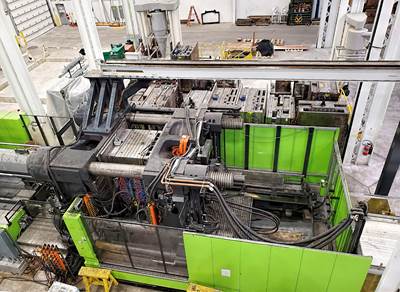

In Oshkosh, Wis., where EVCO focuses on larger machines, and expanded by 31,000 ft2 in 2019, the company has leased and additional 120,000 ft2 for contract manufacturing and warehousing—specifically new large-scale assembly projects. The company recently added a 1000-ton Engel press to the Oshkosh plant and is expecting arrival of a 4400-ton Engel machine this summer. That will be the largest ever at EVCO, which has two 3500-ton Engels there. Notes Bernie Degenhardt, corporate automation manager, “It will come in 20 containers and take three months to assemble.” It’s intended for agricultural and power-sports applications.

EVCO is expecting its largest press yet, a 4400-tonner that will arrive in 20 containers and take three months to assemble.

EVCO also has completed a 13,000-ft2 expansion of its Advanced Molding Plant (AMP) in DeForest to accommodate new 560- and 720-ton Engel presses, additional warehousing, a new grinding room, and workspace for the automation team. Anna Bartz, director of marketing, expects that the building will need another expansion in the next two to four years.

In Calhoun, Ga., EVCO purchased a second plant, dubbed CAL2 (40,000 ft2), last year, and just started production there in March. It houses EVCO’s first white room, outfitted with high-speed automation, and five bays designated for the firm’s foray into LSR molding.

Outside the U.S., EVCO’s M2 plant in Mexico recently added 17,200 ft2, and its China plant is now leasing a second building (40,000 ft2) for its tooling department.

All told, Bartz says, EVCO now has 10 plants with 1.2 million ft2 total manufacturing space (20% more than this time last year), 265 injection machines, and 1700 employees worldwide. “We added 200 in the last year,” says Bartz, acknowledging that as quite an achievement in times of acute labor shortages. “It’s even more of a problem with COVID illnesses,” she notes. “But fortunately we have great relationships with a lot of technical schools and their professors. We conduct tours for students, and we have internship programs.”

EVCO has the financial heft to combat supply-chain uncertainty by stocking up on control components and even buying five robots to put on the shelf for future use.

Supply-chain snafus are another widespread obstacle that has hamstrung production at many molders. However, EVCO is able to sidestep that challenge in ways that may not be accessible to smaller molders. Degenhardt explains, “Getting components is a big deal. So we have been stockpiling control components, for example. We have had some problems with resin lead times, but it’s getting a little better now. Machine deliveries have been okay—we’ve been lucky to get some from orders canceled by other molders. Robots, in fact, have longer lead times than injection presses. So we recently bought five robots to put on the shelf for later use.”

Investing in Automation

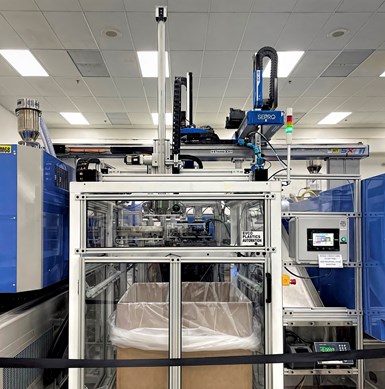

Jason Glanzer, EVCO automation engineer and integration lead, has been focused on high-volume, high-speed automation. “We’re doing a lot of medical kitting with 3D inspection, heat sealing and assembly.”

Adds Brandon Westra, automation engineer, “We had 20 molds built to run parts for two assembly systems with UV cured adhesives.”

EVCO’s automation team is busy with projects like this consumer-packaging cell that ties together two injection presses with 16-cavity stack molds to produce mating parts that are conveyed, snapped together, packaged, labeled and inspected, after which data on each assembly is read via barcode and uploaded to a production and quality database in the cloud.

Such assembly systems are typically built in-house by EVCO’s automation team; but given the accelerating pace of new projects, they have sought outside help. For example, Germany’s Ilsemann Automation helped EVCO’s team build the first of an intended four cells for packaging components. As described by Glanzer, each cell will have two Husky presses, each with a 16-cavity stack mold and custom-built side-entry robots, operating on an 8- to 12-sec cycle with 1.5-sec takeout time. Parts from both presses travel on a common conveyor to an assembly station where the mating parts are snapped together. All parts are weighed and inspected by metal detectors and layer-packed in gaylords. These systems are one of the first candidates for implementing EVCO's SCADA (supervisory control and data-acquisition) system.

Degenhardt describes another large cell for COVID DNA test kits in the MED facility. It collects six different parts from six injection presses. One of those parts is a fluid-filled vial—itself an assembly of three parts from a different cell. The test-kit cell uses several feeder bowls, an assembly conveyor, label wrapper, Tyvek sealing, vision inspection and a barcode reader to send production data to the cloud for access by the plant computer system. “This is new for us—using a SCADA system to collect data from the production line and send it to the cloud, so we can verify production quantities and quality data in real time. The cell is designed to make 70 million test kits a year.”

Since 2018, EVCO has supplemented its conventional molding takeout robots with the newer category of collaborative robots, or cobots. “Cobots are a popular topic of conversation around here,” says Glanzer. “We have more and more contract-manufacturing business, which creates more opportunities to use cobots for inspection and assembly.” In particular, he notes, “We are working on using them to pick inserts out of a bin and hand them to a faster robot for insertion into the mold. Cobot bin picking offers a higher degree of flexibility in terms of part variations than using traditional bowl feeders for manipulating and feeding components—especially with the help of 3D vision systems."

Glanzer says his team currently favors Fanuc cobots, which in his experience have proven to be cost-effective with reasonable lead times. EVCO uses safety scanners rather than hard guarding around cobots. He notes that the Fanuc cobots can downshift from high-speed production mode to slower “cobot mode”—or even stop entirely—when a person enters its safety envelope.

Entry into LSR

As reported last year, EVCO outfitted its new CAL2 plant in Georgia with five bays for LSR molding, a new venture for the company. “We had been thinking about LSR for five years,” says Degenhardt. The first machine, a 130-ton Engel tiebarless press with Nexus LSR dosing system and Engel viper robot, is located in the DeForest Innovation Center, where it has been used for development purposes over the past year. Degenhardt is impressed with the integration of the robot and machine: “They share a common controller, so the machine always knows what the robot is doing and vice versa, so there are no crashes and we can optimize the cycle time. Since February, the EVCO team has gained confidence to transition into LSR commercial production. “We’ve been awarded a few programs in medical and lighting,” notes Degenhardt.

3D Printing Proves a Good Fit

When EVCO got its first plastic 3D printer in 2014, the goal was to produce parts for internal use—jigs, fixtures and other assembly components, as well as R&D prototypes. “Additive manufacturing pushes the boundaries of part design,” says Degenhardt, “and there’s a lot less risk involved in testing concepts this way.”

EVCO operates 15 3D printers mainly for internal prototypes and automation components, but limited production business helps pay for these machines and materials.

Now that the company has 15 printers, such internal uses are still the dominant purpose for those machines. But in 2020, the COVID-19 pandemic demonstrated their value in making production parts on short notice. “We printed headbands for a proprietary face shield while we waited for steel to be cut for injection molds,” recalls Bartz.

She says EVCO is not really looking for short-run business in additive manufacturing (AM). However, she acknowledges that a small amount of such business “offsets the cost of new printers, materials, labor, etc. so we’re able to produce things like CMM fixtures, automation components and prototype parts. Keeping the amount of production frees up the printers for our Innovation Center team to test new tooling, fixturing and other protyping.”

Currently the main AM production business that helps pay for the printers’ internal uses is iPhone cases of a carbon-fiber filled nylon with a metal insert. Explains Bartz, “The insert allows consumers to attach scopes and photography equipment to their iPhone. Given the frequency of iPhone design changes, it’s not cost-effective for us to cut new steel with every new release, which is why 3D printing is a sound production solution.”

Most of EVCO’s printers are MarkForged models that use filament extrusion. But the newest model is an SLA (stereolithography) type that uses liquid resin and photocuring. “It provides very high resolution and no lines between layers,” says Degenhardt. He also notes that EVCO uses outside vendors to produce metal parts by AM, such as robot end-of-arm tooling, conformal cooling channels for injection molds, and prototype cavity/core sets. What about getting their own metal 3D printer? “It’s on the wish list,” he replies.

Related Content

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreVariable-Diameter Air Ring Cools Film Above Frost Line

Tower-mounted adjustable ring adds cooling so that blown film can run at optimum line speeds with structures having soft inner skin layers that tend to block.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreRead Next

More Milestones for EVCO Plastics

Custom injection molder is adding floorspace, machine capacity, and contract manufacturing capabilities at multiple plants in the U.S. and Mexico.

Read MoreEVCO Plastics to Add White-Room and LSR Molding

New plant in Georgia has room for 20 injection machines, including the company’s first LSR molding presses to enhance its medical capabilities.

Read MoreFull Plate of New Technologies on the Table at EVCO Plastics

A new low-pressure molding process, 3D printing of production parts and prototype tooling, collaborative robots, and process monitoring with automatic QC are all on the menu.

Read More

.png;maxWidth=300;quality=90)