‘ECO-ECONOMICS ’: Harbec Plastics Proves It Pays to Be ‘Green’

On-Site: Harbec Plastics

Bechtold has spent 15 years in an ongoing quest to prove that manufacturing in a sustainable manner is not opposed to profitability. On the contrary, he says his experience shows that sustainability is an economic opportunity that manufacturers can’t afford to miss.

Bob Bechtold has a sense of mission—or perhaps multiple missions. One of them is for his company, Harbec Plastics, to thrive in custom precision injection molding while operating in a sustainable manner. Another, more personal, mission is to combat a common misconception in business: “Being Green is nice, but we can’t afford it.”

Bechtold has spent 15 years in an ongoing quest to prove that manufacturing in a sustainable manner is not opposed to profitability. On the contrary, he says his experience shows that sustainability is an economic opportunity that manufacturers can’t afford to miss. It’s largely about minimizing sheer waste of energy—kWh or Btus that you paid for but did not utilize their full value—and utilizing the most economical and most reliable sources of energy available to your business. Not only should those principles make dollars and sense to any businessperson, but Harbec has found that they also can help a company slash its carbon emissions that contribute to global warming. Bechtold calls his philosophy of combining manufacturing economy with environmentalism “eco-economics.” It’s not only a profitable strategy but a marketing tool that Bechold believes will become increasingly valuable, if not essential, in global markets.

NOT ALWAYS EASY BEING GREEN

Being a pioneer has its pains and rewards. Bechtold spent a lot of time, money, and personal energy in struggles with local authorities and electric utilities that were not sympathetic to his eco-economic ambitions—though attitudes have changed considerably over 15 years. Harbec pushed boundaries and tried things that had never been done. It made some mis-steps and also reaped some unexpected windfalls. It won awards and honors. And it is even now embarking on new efforts at the frontiers of eco-economics.

Bechtold founded Harbec, Inc. in 1977 as a tool-and-die job shop in Webster, N.Y. In 1987, he moved to his current location in Ontario, N.Y., near Rochester, and wanted to get in on the action in plastics moldmaking. But molders were reluctant to entrust their tools to a newcomer, so Harbec jumped into molding to gain credibility.

Today, Harbec is an injection molding company that builds 90% of its own molds and 100% of its models. It has explored new technologies for moldmaking, like direct metal laser sintering (DMLS) and use of aluminum for both prototype and production molds. With DMLS and a novel technology for metal injection molding, Harbec is developing a sideline in producing metal parts more efficiently and cost-effectively than by traditional die-casting or CNC machining.

Harbec occupies 40,000 ft2 and employs 150 people. It operates 24/5 with 32 all-electric injection machines from 9 to 400 tons. Its $15 million annual revenue is almost evenly divided among automotive, aerospace/defense, medical, telecom, and sports/leisure industries. Automotive was its first, and is still its biggest, sector, but Bechtold is focusing on medical for future growth in Harbec’s niche of short- and medium-run production.

“We don’t so much pursue a particular market as a type of customer—one that’s innovative, progressive, and generates a significant number of new products.” For Bechtold, medical customers fit that bill. The firm has a brand-new, temporary Class 100,000 clean room and is planning a 17,000 to 20,000 ft2 expansion next year that will include a permanent clean room. “We have ideas on how to make it the most energy-efficient clean room in existence,” Bechtold says.

Always interested in environmentalism, Bechtold started pushing his company in that direction in the 1990s. In 1998, he sought funding to invest in alternative energy sources—first of all, for straightforward business reasons. “The number-one reason for businesses leaving N.Y. State is the cost of energy—the third highest average in the U.S. I had a choice of joining that exodus or finding a different way.” Harbec was paying about 15.5¢/kWh back then (around a penny less now), but also faced sporadic brownouts and power surges that damaged the circuit boards on his machines—costing him as much as $15,000 in one month alone.

Bechtold developed a plan to generate his own power with a combination of gas-powered turbine generators and wind energy. He presented the economic justifications for the co-generation project to potential lenders—but, in retrospect, he concedes he erred in leading off the discussion with the project’s environmental benefits. “I was naïve. I had my passion. But I branded myself as a tree-hugger or burned-out hippie.” He also shocked the bankers by projecting payback for the project in seven to 10 years, not the usual two to three years.

After being turned down by 30 banks over the course of two years, he rethought his approach. He advises anyone who would follow in his footsteps to present sustainability projects solely in economic terms, and don’t even mention the environment—“the other e-word,” as he calls it. Following his own advice, he eventually obtained funding from a consortium of one bank and four state economic-development agencies in 2000.

Even then, his first project encountered delays and cost overruns due to an unfortunate choice of gas-turbine supplier. But Bechtold then found his solution with Capstone Turbine Corp., Chatsworth, Calif. Capstone’s microturbines are like miniature jet engines that burn natural gas to drive a small electric generator. In 2001, Harbec installed 25 micro-turbines, each capable of generating 30 kW, for a total of 750 kW capacity. Harbec’s maximum load is 500 kW, so that leaves 250 kW backup for maintenance or unexpected needs.

About the size of a refrigerator, the turbines have only one moving part and are maintained by Harbec personnel trained by Capstone. At the time, his was the biggest installation ever of gas microturbines, and control technology had to be developed to coordinate such a large number of units. Their average life is said to be 25 yr.

Harbec paid $1.1 million for the micro-turbines, which they paid back in a bit more than seven years. Now, with a grant from the N.Y. State Energy Research and Development Authority (NYSERDA), Harbec plans to replace 16 of the 30-kW turbines with eight new-generation 65-kW models.

COMBINED HEAT AND POWER

Since 2001, Harbec has seen its costs for natural gas fluctuate from $3/MBtu to $12 and back to $6. “I don’t care which way gas prices go,” Bechtold says. The good thing about co-generation with micro-turbines, he explains, is that he can switch from electrical priority to thermal priority and back, as justified by current economics. That means that when gas co-generation is less expensive than purchased electrical power, he can fire up enough turbines to power his plant. When gas is more expensive, he can shut down turbines and purchase just enough gas for his plant’s heating and cooling needs. That’s why Bechtold calls his system Combined Heat and Power, or CHP.

According to figures Bechtold has seen, standard fossil-fuel powered electrical generating is only 25% efficient—75% of the fuel energy is wasted (some lost in long-distance transmission). Capstone’s micro-turbines are about the same, at around 28% efficiency. But when you utilize the leftover combustion energy, which normally just goes “up the stack,” for in-plant thermal tasks, you can raise the overall fuel efficiency above 70%, Bechtold claims.

With five heat exchangers, Harbec uses that “waste” heat to create hot water that does five different jobs:

1. Some of it flows through 17,000 ft of 1-in. tubing to provide in-floor radiant heating in the newest portion of the plant (17,000 ft2 added in 2001).

2. A watger-to-air heat exchanger delivers hot and cold water to the rest of the plant’s HVAC system.

3. One absorptive chiller connected to an evaporative cooling tower converts 210 F water to 44-47 F water for air conditioning.

4. Harbec is helping another company, Ener-G-Rotors, Schenectady, N.Y., to commercialize a device that uses an organic Rankine cycle to convert low-grade heat into electricity. It takes in 220 F hot water and gives back 200 F water, which is still able to meet Harbec’s heating/cooling tasks, while generating up to 30 kW of electrical power.

5. A biodiesel plant located next door converts waste cooking oils into biodiesel fuel and bioheating oil. Hot water piped in from Harbec’s CHP system is used to power the chemical conversion process., while an oil-fired boiler is maintained as a backup device. This arrangement saves up to 100,000 gal of fuel per year.

Bechtold cannot hide his excitement when he points out that all these heating/cooling functions are free—powered by energy that would otherwise be thrown away. CHP also produced one of the most pleasant, and profitable, surprises in Harbec’s experience with green energy.

Free air conditioning of his molding plant not only provides a more comfortable workplace for his employees, it also eliminated what was the firm’s number-one quality issue—moisture contamination of hygroscopic resins. “We use a lot of engineering resins,” says Bechtold, “and during May to September, we had as many as 25 dryers running nonstop.” But with less humid air in the plant, Harbec now runs only five dryers year-round, and saves a lot of electricity and scrap material from reject parts.

Another side benefit of “free” heating and air conditioning is that Harbec is able to improve the quality of its workplace by nearly eliminating the pervasive smell of hot plastic that permeates workers’ clothes and goes home with them at the end of a shift. Harbec places an air exhaust hood around the nozzle area of each press and vents that air outdoors. It quadruples the amount of air exchange in the plant, which would be prohibitively costly without micro-turbine CHP.

HARVEST THE WIND

Today, Harbec’s CHP system provides one-sixth of the plant’s power needs of 3 MM kWh/yr. Two–thirds of its needs come from wind power. Despite much resistance (again) from local authorities and the power company, Harbec installed a 250 kW wind turbine in 2003 and an 850 kW unit in 2012. “That allows us to predict two-thirds of our energy costs 20 to 25 years into the future!” Bechtold enthuses. The first turbine needed only 40 hr of maintenance during its first 10 years.

Harbec’s first unit paid back its $400,000 cost in seven years, 10 months. In general, wind-power ROI today is eight to 10 yr, Bechtold says, depending on the price of electricity. He knows this will sound alien to molders who normally want two- to three-year payback on capital equipment. “But this is completely different. You’re just taking the dollars you would be paying to the utility company and paying them to the bank instead. The difference is that at the end of the term, you have an asset that keeps delivering savings to your bottom line for 10 to 15 more years. And you have eliminated uncertainty about what that energy will cost.”

Times have changed. Though it was a struggle to get funding for the first wind turbine at Harbec, when Bechtold sought bids for the second, four offers came in virtually overnight. “Two of them required no risk, no out-of-pocket by us,” marvels Bechtold. “They would build the turbine at their own expense and sell us the energy through a purchase agreement. So, you see, today a manufacturer can actually leverage his power consumption!”

There’s more on the agenda for renewable power at Harbec. Besides the ongoing trial of the Rankine-cycle generator that will skim just 10° to 20° F off the top of Harbec’s “free” hot-water stream, by the time this article is printed, Bechtold hopes to have received funding approval for a 500 kW solar “farm” to be installed in a field underneath the wind-turbine towers.

MORE WAYS TO SAVE

One of the simplest ways for any plant to save energy is to replace interior lighting with more efficient T-8 type fluorescent bulbs and reflectors. Harbec completed a full plant lighting upgrade in 2007 with a $65,000 investment, paid for in part by a NYSERDA grant for $16,000 and a Federal tax credit of $8000. Lighting energy consumption was reduced by 48% on average, saving $38,000/yr. Also, the bulbs last longer, and their fuller spectrum improves the quality of lighting, Bechtold says. He figures his ROI for that project at 18 months. “If you don’t upgrade your lighting, you’re just throwing bucks away.”

There’s also free lighting in the newest part of the plant, which has skylights sufficient for daytime lighting except on the cloudiest days. Sensors automatically turn on the lights when needed.

The 2001 building expansion was built to LEED (Leadership in Energy and Environmental Design) standards, with “daylight gathering” (skylights), in-floor radiant heating, and double-insulated walls and roof built with structural insulated panels to minimize heating and cooling losses.

Starting back in the early 1990s, Harbec replaced every one of its hydraulic injection presses with all-electric models and has bought no other kind ever since. For Bechtold, it’s another no-brainer, as these machines use up to 50% less energy than conventional hydraulic machines; are cleaner and quieter; produce less scrap by getting on cycle faster at job startup; and they throw off much less heat into the work environment. (Bechtold compares a hydraulic press to “running a pizza oven with the door open on the shop floor.”)

In 2009, Harbec upgraded its molding machines with barrel blankets or insulation to save energy. It reduced the machines’ electrical consumption by 40% (324,000 kWh/yr), saving $44,000. Here, again, Harbec experienced a pleasant surprise: The reduction in wasted heat emissions to the plant environment trimmed the load on the air-conditioning system by 12 tons of air cooling, or 12 kWh/hr.

For the future, Harbec is investigating more efficient screw designs to save energy. It is also looking into “peak-shaving technology” that would use large storage batteries to reduce its peak electrical consumption charges. At present, it minimizes startup loads by assigning one person to come in on Sunday night to start up all the machines. That means only one machine can be started up at a time.

Other energy-saving initiatives include installing soft-start controls and variable-speed electrical inverter drives on a variety of auxiliary equipment (such as air compressors), and converting to a company fleet of fuel-saving hybrid, electric, and biodiesel-powered vehicles. It recharges its electric vehicle batteries with renewable power at the plant.

CONTINUING IMPROVEMENT GOALS

From 2005 to 2008, Harbec increased sales and profits each year. Yet the EPA Green Power Partnership reports that Harbec’s annual electric consumption dropped by 35%, saving 1.225 million kWh or $189,875 annually, which also means 919 fewer tons of CO2 greenhouse gas emitted to the atmosphere.

Bechtold says with confidence, “We’re going to be a carbon-neutral company by the end of this year.” That means Harbec will be responsible for zero net emissions of CO2. How will that be accomplished? Right now, Harbec purchases one-sixth of its electric power from the utility grid. And for that amount, Bechtold buys only “green power,” which the utility supplies by purchasing carbon credits, or offsets, on the commodities market. Harbec plans to offset its natural gas purchases for CHP by purchasing its own carbon credits as well. Next year, the need for credits may be reduced by the new solar panel installation.

Besides belonging to EPA’s Green Power Partnership, Harbec is an EPA EnergyStar member and participant in that agency’s Climate Leaders program. Harbec also received a 2011 Manufacturing Extension Partnership (MEP) Excellence in Sustainability Award from the National Institute of Standards and Technology (NIST).

Harbec is already certified to the ISO 9001 quality standard and ISO 14001 environmental standard. This month, it aims to be one of the first firms in the world to be certified for ISO 50001, a new international standard for energy-efficient manufacturers. Harbec is going even further to meet additional requirements of the U.S. Dept. of Energy’s Superior Energy Performance (SEP) certification program, which would put Harbec in company with the likes of Dow Chemical, 3M, Owens Corning, General Dynamics, and Nissan North America.

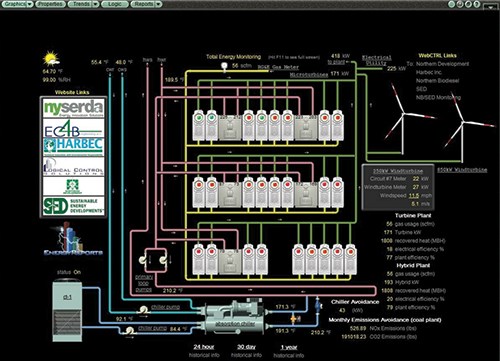

Harbec is also participating in DOE’s Better Plants Challenge, along with Ford, Honda, and 10 other for companies that will commit to spend at least $1 million for energy efficiency in the next year, and will publicly document the results of that investment. That’s why Harbec started a web page, accessible from its website or from a separate Harbec site (www.northerndevelopment.com), which presents an electronic dashboard showing the performance of the plant energy system (CHP and wind), both real-time and trends, for where and how much power is being generated and consumed. Harbec uses that dashboard on an oversized screen in its control room to monitor the plant. “That way, we’ll know immediately if a process or piece of equipment is generating or using more or less energy than usual,” says Bechtold.

He believes such energy transparency will be an important marketing tool in the near future. “Wal-Mart is developing a label to show a supplier’s carbon and water footprints and all environmental impacts,” he says. He sees eco-labeling as of immediate value in Europe. “We sell in 26 countries,” he notes. Bechtold concedes that the U.S. will take longer, although Wal-Mart and some large industrial and consumer brands, from IBM to Coca-Cola and Procter and Gamble, are already showing interest in eco-sensitive manufacturing.

And when the change comes in force to the U.S., Bechtold says, Harbec will be well ahead of its competitors. “Other molders may have to go out and spend some money buying carbon credits to satisfy OEMs. But we won’t and that will give us an edge in pricing and profitability.”

While every box of Harbec product is stamped with a footprint logo that conveys the message of “No carbon footprint by 2013,” a companion logo is being added with the message of “No H2O footprint by 2015.” Harbec’s next goal is to be “waterneutral” (like carbon-neutral) in two years.

The company built a pond to supply water for fire-protection sprinklers. But that 800,000-gal reservoir also captures and holds rainwater from the building roof and parking areas. It uses the pond as a large heat exchanger to condition hot water from the CHP system after it has performed other tasks. “Leaving just 2° F from that water stream in the pond saves us 900,000 gal/yr of water to finish the job in our evaporative cooling tower.”

Bechtold explains, “Our goal for 2015 is to use city water only for drinking or handwashing. Everything else will use recycled water. And if we need to, we will purchase water credits (analogous to energy credits) to reach our goal.”

Related Content

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MorePregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=970;quality=90)