Extruder Upgrades Pay Off Big for Sheet Processor

Extrusion

A $65,000 upgraded paid for itself in less than a month.

To what extent can a well-designed screw and barrel improve the efficiency of an extrusion operation? A leading sheet extruder and thermoformer recently found out. A $65,000 upgrade to these key extruder components made last year by this major North American packaging supplier paid for itself in 25 days.

The processor, which requested anonymity, worked with well-known extrusion consultant Chris Rauwendaal of Rauwendaal Extrusion Engineering (REE), Auburn, Calif., to refurbish an extrusion line at one of its plants dedicated to polystyrene cups. This particular line has no oven to reheat the PS sheet before thermoforming. Instead, it relies on a series of four small rolls to cool the sheet to the optimum temperature just prior to inline forming.

While very compact and energy efficient, this type of setup places high demands on the extruder to maintain a homogeneous melt at a consistent temperature, Rauwendaal explains. “Because sheet cooling is limited, melt temperatures must be kept low to achieve high line output,” he states.

But the line had been giving this processor problems for months before the firm called in Rauwendaal. For one thing, the melt temperature was too high (473 F). The extruder temperature profile was set to minimize the melt temperature, but resulted in vent flow of more than 1000 lb/day. Excessive barrel cooling was also necessary to achieve this melt temperature.

Second, oil was building up on the cooling rolls, requiring regular cleaning that resulted in extra line stoppages. Moreover, maximum forming speed was limited to 25 cycles/min, and the line was generating many poor-quality cups that packers had to remove before shipping.

The extruder barrel had a non-standard internal diameter; the ID had been honed to 4.51 in. and had significant scouring in zone 6. And it turned out that the screw, which had been designed by REE, was not manufactured correctly: A cut on a mixer at the end of the screw was never finished. So at REE’s recommendation, the processor bought a new extruder barrel with high-efficiency air cooling. The Rauwendaal screw was modified to correct the manufacturing issues and increase the clearance in the first-stage mixer by 50%. It was also cut down to fit a standard 4.5-in. barrel.

PLOTTING THE IMPROVEMENTS

In order to quantify the effect of the new barrel and screw, company engineers and Rauwendaal used a data-collection system to monitor extruder screw speed, gear-pump inlet pressure, extruder melt temperature, and barrel heating and cooling. The data was downloaded into a spreadsheet for analysis, then charted based on 22,000 data points collected for each variable in a 50-min run.

This process proved useful in showing how long it took the extruder to reach equilibrium—30 to 40 min, even with all line upgrades. However, a histogram plot of the melt temperatures at equilibrium proved to be the most effective graph to display the effect of each equipment upgrade.

The histogram plot showed that the new barrel and cooling system reduced the extruder melt temperature by 8.4° F, allowed the barrel-temperature profile to be adjusted as desired, eliminated the extruder vent flow, and allowed an 8% increase in output.

The modified REE screw in the new barrel with the new cooling allowed a further reduction of 26.3º F in melt temperature; an additional 4% increase in output; a dramatic increase in cup quality (no damaged cups, best quality ever off the line); faster startups—since the line could be started at full regrind level of 53%, rather than gradually increasing it to the thermoforming tool’s scrap rate; and allowed external regrind addition without adversely effecting quality.

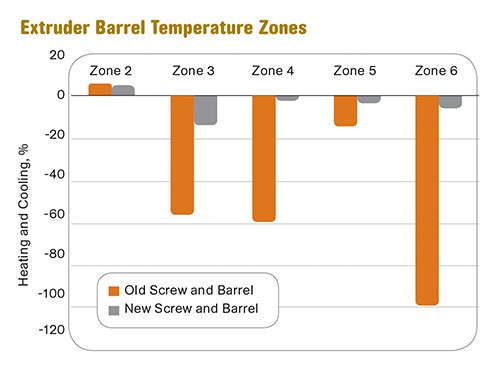

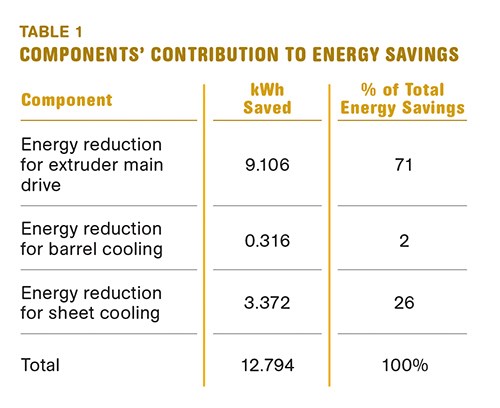

The processor and REE also charted heating and cooling at the temperature zones along the extruder barrel. This demonstrated that the new screw/barrel combination required significantly less cooling to maintain barrel-temperature setpoints. The components of energy savings are shown in Table 1. With average energy cost of $0.10/kWh, the daily cost savings through reduced energy consumption come to $30.70.

A bigger payoff for the processor came as the result of a drastic reduction in vent-flow scrap. “The new screw and barrel cut the previous vent-flow waste from more than 1000 lb/day to less than 50 lb/day,” the company says. “Savings related to vent scrap alone amounted to $780/day.”

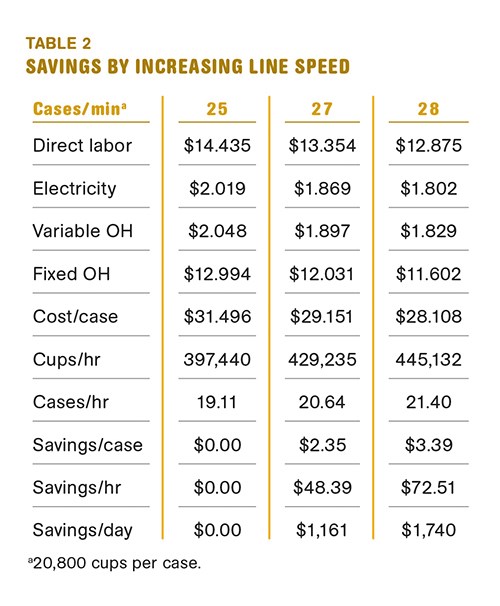

The most significant improvement in manufacturing cost comes from the ability to run at higher line speed. Table 2 lists the cost factors associated with line speed. At a line speed of 28 cycles/min, the total savings amount to $2550/day. For production of 300 days/yr, this amounts to savings of $765,000 annually. Says the sheet processor, “The cost of the extrusion upgrades was $65,000. With savings of $2550/day the payback was only 25 days—less than one month. Over the first year the extrusion upgrade resulted in net cost reduction of $765,000.”

The Rauwendaal screw will be retrofitted on another line at the processor’s plant.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)