Extrusion & Compounding at NPE: More Output, More Flexibility, Less Energy

NPE2012 Preview

There won't be many blown-film lines running, but there is still much in the way of innovation going on in extrusion and compounding.

The high-rise film bubbles might be harder to find, but the machines are definitely returning to NPE for next month’s show. In both individual extruders and complete systems, processors will notice that machine builders have put their engineering firepower to work to develop equipment that highlights speed/output, flexibility, simplicity and—perhaps most critically—energy efficiency.

Davis-Standard will have a fleet of extruders on hand and will be running a line producing geothermal HDPE pipe. A 2-in., 34:1 extruder in that setup features what Davis describes as an “intensely cooled” grooved feed section designed for bimodal PEs and other polyolefins. A new screw design offers a troika of benefits: low melt temperature, high output, and better mixing and melt homogeneity.

Davis is also taking the wraps off a 3-in., 40:1 high-speed extruder with a high-volume feed section and electrically heated/air-cooled barrel. This extruder is targeted for PS and PP sheet and in-line thermoforming. Davis maintains that for these applications the 3-in. machine can match throughputs of extruders twice the size with no sacrifice in melt temperature and pressure stability.

Meanwhile, a 3.5-in., 30:1 model of Davis’ Mac extruder line features a more streamlined design. This series of high-performance, air-cooled extruders is engineered for nine-layer film.

The company’s new Medical Extruder Direct Drive (MEDD) machine offers a direct-drive motor for more energy-efficient operation. You’ll notice flexibility here: The extruder features interchangeable barrel assemblies (1-in., 24:1 can be swapped with ¾-in. 24:1) to accommodate a wider range of materials.

American Kuhne will also showcase new extruder designs. Among them is the E³ Energy Efficient Extruder, a 3.5-in., 24:1 air-cooled machine that includes a combination of mechanical and electrical design improvements that are projected to save at least 15% in energy use. Areas of improvement include barrel heating and cooling, drive and motor, feed section, gearbox (gearless operation optional), and controls.

American Kuhne’s Convertible extruder is also engineered for flexibility. It enables fast and easy transition from a 3-in. smooth bore to a 2.5-in. grooved feed. This feature is designed chiefly for blown film lines that “swing” between HMW-HDPE (where grooved feed is the standard) and the smooth-bore processing most processors use for LLDPE blends.

Welex will show a Mark III high-performance extruder. The line ranges from 2.5 in. to 10 in., and can be specified in 24:1 to 40:1 L/D. The extruders have direct-coupled drives and usually include positive closed-loop liquid cooling. The machines have fixed-ratio, high-torque gear reducers.

New Max Impact feedscrews from R&B Machinery are made of carbon steel with bimetallic flight hard-facing and chrome plating for extended life. R&B will also display a new 2.5-in., 24:1 air-cooled Max extruder with discrete controls, cool-to-touch heaters, and a single-bolt clamp swing. It will also showcase its extruder-rebuild services.

WHERE HAVE ALL THE BUBBLES GONE?

NPE used to rival the German K Show in the number of blown film lines operating at the exhibit. That has waned a bit over the last couple of NPEs, due mostly to the expense involved and the compressed time frame within which builders have to put up and tear down a complete line.

One notable exception at this show is Macchi SpA . The Italian machine builder will be running a three-layer line with a variety of polyolefins in an A-B-C configuration. A pair of 2.5-in., 30:1 grooved-feed, air-cooled extruders will feed the outside layers, and a 3-incher will pump material to the core of the structure. The line also will have a 12-in. die and IBC package, as well as Macchi’s CR-K2 auto-gauge air ring. The air ring and IBC intake air will be supported by a self-contained chiller and heat-exchanger.

The three-layer line will be furnished with a variety of other bells and whistles, including a Doteco gravimetric batch-blending and vacuum-conveying system, Macchi’s Easy Control line supervisory control, and Kundig’s Rotomat K-300 scanning capacitance gauge. Macchi’s own horizontal oscillating haul-off includes a post-nip chilled S-wrap web-cooling system and a collapsing frame with carbon-fiber rollers. The system will also be equipped with back-to-back surface winders with axial/gap winding and slitting capabilities, plus in-line trim-removal and repelletizing.

Most other blown film equipment suppliers will focus on advances in key components. Two new developments from Addex continue that supplier’s emphasis on gauge-control enhancements. Addex is offering a new gauging system in which the sensor is located within the collapsing frame itself, enabling it to accommodate a wide range of layflat widths. In beta testing, one film processor reportedly ran the system with layflats ranging from 30 to 100 in.

When integrated with Addex’s air-ring-based External Gauge Control System, the unit offers simplified installation by eliminating time-consuming wiring. Addex can also supply a two-sensor system allowing readings to be taken on both sides of the frame to speed up both measurement and response times of either the air ring or its Internal Gauge Control system.

Addex is also offering a new infrared-based sensor permitting online thickness measurement of barrier materials such as nylon and EVOH within multi-layer structures. Unlike nuclear systems, IR technology is not susceptible to material density variations and can differentiate between layers as opposed to providing a thickness average.

The third-generation IBC control system from D.R. Joseph incorporates new automated features to optimize performance and maximize output while maintaining tight tolerances. New features include automatic valve calibration, ducting failure detection, automatic sizing-cage control, auto layflat control, and integrated data collection.

Also new is D.R. Joseph’s LF Sizer, a non-IBC layflat-width controller. Using much of the same technology as its IBC system, the LF Sizer measures and controls layflat variation to cut down on scrap production; it controls bubble breaks due to pinholes and speeds start-ups and size changes.

Finally, D.R. Joseph is rolling out the Seal-Cut high-speed sealing system offering a solution for machine-direction sealing by reversing the process known as slit-seal. The Seal-Cut is capable of converting one large roll into two smaller rolls to save on production costs (compared with running two smaller lines to meet the same order requirements). Sealing at a lower temperature is also said to mitigate against polymer crystallization, resulting in a stronger and cleaner seal.

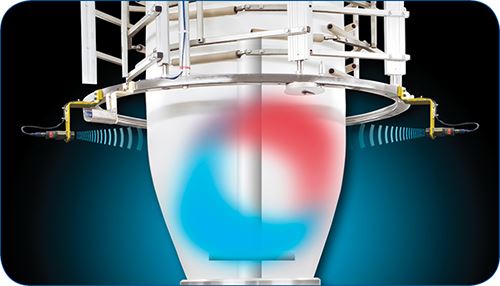

Brampton Engineering will unveil the eCool IBC control, described as a cost-effective solution for upgrading existing IBC lines. The system dramatically improves bubble-diameter control by using three temperature-compensated ultrasonic sensors to continuously monitor the tube. A proprietary algorithm then controls the supply blower speed to maintain the required bubble size. The additional sensors vastly improve time-sensitive corrections and enhance performance and reliability, Brampton says.

The eCool system also includes automatic blower balancing and provides an alarm output in the unlikely event of a bubble break. Additional options include automatic layflat control and cage control.

In dies, Brampton will be showing a new FlexStack SCD (Streamlined Coextrusion Die) with a die profile that’s 50% smaller than previous designs. Available for five to 11 layers, the die’s compactness, combined with its streamlined distribution and spiral design, offers short residence times, which translate into quick material transitions for reduced scrap and minimal gel formation and carbon buildup.

Macro Engineering will showcase its latest nine-layer blown film die. It’s an iteration of the company’s TaperPack stackable die design, which Macro uses on smaller lines and its double- and triple-bubble systems. On this design, the extruder adapter heights are all level, so extruder centerline heights don’t need to be staggered. This reportedly simplifies installation and frees up space in the area allotted for the extruders.

With a short residence time and the ability to carefully fine-tune individual layer temperatures and thicknesses, the new die provides latitude to process a wide array of material combinations that include barrier structures with nylon and EVOH. The die is available for up to 11 layers and can be outfitted with IBC hardware and Macro’s Accupro automatic gauge-control die-lip heaters.

Davis-Standardwill take the wraps off its Vertex coextrusion die, engineered for film applications requiring multiple resin changes. Advantages include highly efficient IBC, low surface energy, high shear rates, tight gauge distribution and control, and minimal residence time and pressure.

The die’s concentric design has spiral channels fed from a vertical binary network with round flow passages to eliminate typical degradation areas, thus promoting fast purges and quick product changeovers. Computer-designed channels maximize melt homogenization, gauge control, and film properties over a range of formulations. The die’s high shear rates and low surface energy keep the die surfaces clean.

It is also built with a minimum number of components for simplified maintenance. Davis-Standard will exhibit a 12-in., three-layer Vertex model at the show, available in diameters up to 86 in. Davis is also exhibiting a 12-in. triple-lip air ring for superior cooling rates and film quality.

Gloucester will also display innovations in the areas of dies, film cooling, and winding, as well as new multi-wrap technology for stretch films, designed to seamlessly integrate with existing Gloucester winders. Further details were unavailable at press time.

Speaking of winding, Brampton will show new FlexWin blown film gap turret winders, claimed to be the most versatile available. They can wind in center and surface mode and any center-surface combination ratio. The center-surface winding combination allows the FlexWin to wind in center mode with surface assist. This is accomplished by driving the winding spindles and lay-on roll with gearless direct-drive servo motors for precise motion and tension control.

The winders are said to produce perfectly wound rolls regardless of film thickness or whether films are slippery or tacky, rigid or extensible, stiff or supple, etc. Additional features include bidirectional gap winding and tapeless zero-fold-over cutoffs for perfect roll starts with Brampton’s new patented Zip knife.

Hosokawa Alpine will be linked to its seven-layer line at Dow in Freeport, Tex. Dow will be processing some unique formulations and expects to be running with Alpine’s new high-throughput V-ring, which increases rates by 25–50% and improves bubble stability and total gauge control. Alpine has installed several of these air rings as part of a retrofit system upgrade with the Alpine X-die. The result is significant quality and output improvement and a typical return on investment of months.

Concerning line controls specific to blown film, Brampton’s Italycs 5 is said to combine the latest software and hardware technologies to deliver a more robust, secure, and powerful line supervisory and control system.

It is also billed as more user-friendly with faster response and simplified access to various sections. The controller incorporates real-time and historical trending of critical process variables to maximize quality and productivity.

CAST FILM, SHEET

Where flat film is concerned, Breyer GmbH has developed new technology permitting processing of high-speed, low-shrinkage photovoltaic encapsulation films based on EVA. The new system produces tension-free film by eliminating cast rolls or calenders from the line; the film is produced at lower-extrusion temperatures, making annealing systems unnecessary.

Breyer adds that the system also permits film winding without a PE-based interlayer because of the “special surface” of the EVA film. Further, Breyer maintains that the system does not require use of so-called carrying paper or packaging.

In sheet, Processing Technologies International (PTi), will be showcasing its unique “dryerless” twin-screw sheet extrusion production system, and a new three-position turret winder. The sheet extrusion system can achieve rates above 2000 lb/hr with a variety of resins, including post-consumer and post-industrial PET or PLA.

The energy-efficient process relies on Luigi Bandera’s patented High-Vacuum Twin-Screw Extruder (HVTSE) technology, which allows PET to be processed without the need for drying and crystallizing.

HVTSE employs a single atmospheric vent and dual high-vacuum vents on a co-rotating twin-screw extruder. This novel approach allows moisture and other volatiles to be removed during extrusion. In the case of recycled PET, this is also said to eliminate the need for re-crystallization. The energy savings from cutting out drying and crystallization can approach 30-35% . PTi is Bandera’s exclusive North American partner.

PTi’s three-position turret winder is a compact unit that allows slit material to be wound two-up, meaning that half-slit material can be run on two rolls at the same time. The turret winder provides all the benefits of a cantilever design but at a smaller footprint. It has a max. diam. of 40 in., capability for 3- and 6-in. cores, max. roll weight of 4300 lb, and max. width of 70 in.

The unit’s control system is integrated into PTi’s Titan control platform, allowing remote troubleshooting. The winders were initially developed to support PTi’s sheet extrusion systems but are also offered as stand-alone products.

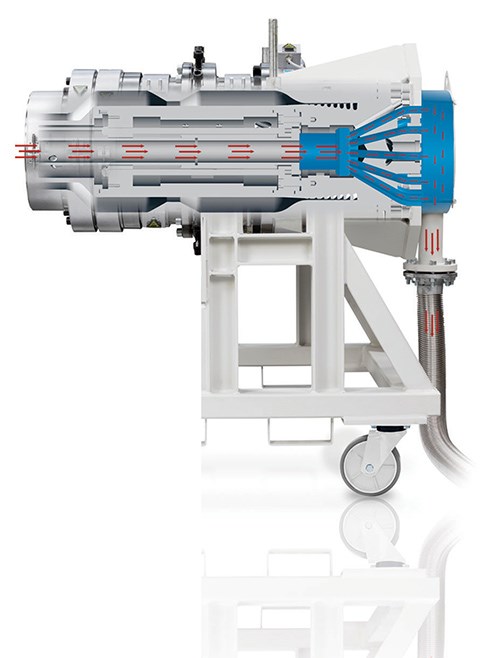

Dryer-free PET sheet production will also be exhibited by Gneuss. It will show a complete extrusion line featuring its Multi-Rotation System (MRS) 130 extruder, a fully automatic filtration system (RSFgenius 150), and an online viscometer. The MRS extruder permits PET processing without predrying, relying on a water-ring vacuum system to extract moisture from the melt.

The unit features a patented processing section consisting of a drum containing eight satellite single screws, driven by a ring gear and pinion transmission. The “barrels” are cut into the drum and are approximately 30% open and provide optimum vacuum exposure of the melt.

Devolatilizing performance is said to be 50 times greater than that of a conventional single-screw extruder—at a vacuum of only 25 to 40 mbar. By avoiding the need for a high-vacuum system and predrying, the MRS is billed as an extremely efficient alternative to conventional technologies. It also offers a simple and rugged design, small footprint, flexibility, and excellent decontamination needed for processing scrap.

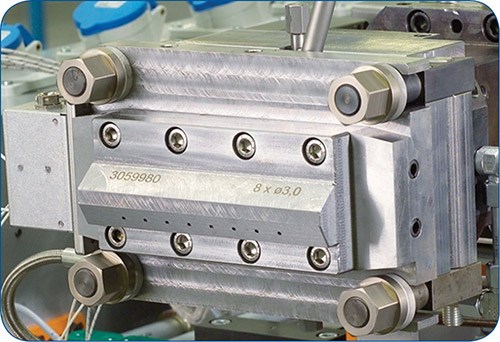

A PS foam sheet die on display at Davis-Standard features spider-less, multi-hole engineering with externally adjusted gap control and concentricity. The three-zone, oil-heated design maintains excellent temperature uniformity. Internal and external air rings, and streamlined flow channels ensure consistent quality. The die also has modular lip inserts to reduce replacement costs.

The cooling and sizing mandrel is of aluminum with spiral water-flow passages. It includes a separate nose with low-friction plating and two zones of water-temperature control. Each zone has flow indicators, flow-control valves, and solenoid valves. The motorized cooling cart is carriage-mounted on a linear bearing with airflow and water controls. A slitter assembly enables slitting at the three and nine o’clock positions.

In sheet line controls, Welex will showcase its Super Sentinel Intelligent Process Control System, which it says offers the maximum in flexibility and line control.

PIPE, PROFILE, TUBING

The uniEX is the latest multi-purpose single-screw extrusion line for pipe and profile from Battenfeld-Cincinnati. Because of what are termed “specialized screw geometries,” the company’s line of singles reportedly can process a wide range of materials, including all polyolefins, PVC, TPEs, and engineering resins. The extruders are said to offer consistently high specific throughputs at every screw speed. An additional benefit is the extremely wide process window.

Boston Matthews is now offering tubing extrusion lines with fully integrated quality-management systems. By using its own Smart Control System as the main platform, Boston Matthews was able to integrate additional quality-management systems—such as those for wall-thickness measurement, tube-diameter measurement and control, lump recognition, defect analysis, and loss-in-weight yield control—into one operating interface.

This eliminates the need for separate mounting and interfacing of separate processing hardware normally associated with add-on quality-monitoring systems. Process and quality data is collated and stored in a single seamless unit for export to either an already established SPC data interface or tailored to meet the exact requirements of the processor. Optional iSmart wireless operation is particularly advantageous to processors that operate with clean rooms or other restricted-access areas.

An Internal Pipe Cooling (IPC) system from KraussMaffei Berstorff (kraussmaffei.com) is said to offer pipe processors higher productivity while reducing energy and upfront investment costs. Compared with conventional pipe-cooling systems, the IPC shortens the cooling section by up to 40% because it uses ambient air to cool the pipe from the inside, in addition to conventional external cooling.

Beta LaserMike will be exhibiting its AccuScan non-contact laser gauge that measures tube diameter and ovality for increased manufacturing accuracy. The latest AS5000 series offers more than twice the measurement rate, at 2400 measurements/sec, with unique facet calibration for high-accuracy, single-scan measurement data.

Beta LaserMike will also be showing its DataPro process controller and data-management system. Said to be simple to operate, this advanced tool continuously monitors product dimensions and automatically controls the line to keep processes and product quality under control. New capabilities include one-touch navigation, printing, enhanced data logging, automatic process control, and Ethernet communication.

COMPOUNDING, RECLAIM

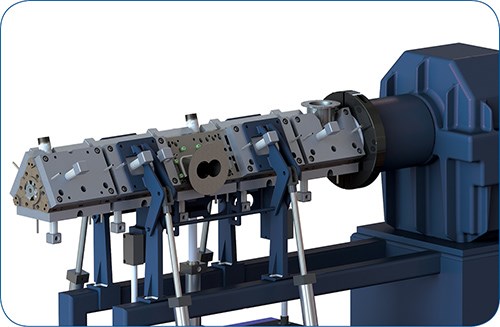

Leistritz’s exhibit will feature its ZSE-40 Maxx twin-screw equipped with newly designed swing-gate strand-die assembly. The swing-gate strand die offers a streamlined transition from the extruder to an oval breaker plate and then to a front-end die plate. Screens are accessed by swing bolts. This facilitates cleaning by allowing the screen-carrier plate to be removed, which exposes the transition region to the screws and the transition into the die. A replaceable multi-strand die plate is integrated into the design.

Leistritz will also display a ZSE-50 Maxx twin configured for both reactive and direct extrusion. Several enhanced lab-size compounding extruders will also be on display, including Leistritz’s nano-16 twin-screw. This unique machine has a 1.2 OD/ID ratio and 1 cc/diam. free volume, a combination that facilitates processing batches as small as 20 g. A patented plunger feeder can be used to push materials into the feed barrel from underneath. The nano-16 will also utilize a TSCS PC-based data acquisition and control package.

Entek will be showing a 103-mm twin that features an all-new base design for easier machine access, as well as 52:1 L/D, a 300-rpm, 600-hp motor, and 93-mm side feeder. Entek will also debut upgraded control functions for its twin-screw extruders. These include enhanced trend monitoring standard on every machine; remote access for 24/7 machine support via the web or phone line (standard); enhanced recipe/formula system (standard) with virtually no limit to the number of recipes that can be stored on the operator interface; and remote storage of trend data.

In addition, the machine builder will feature several new developments through its Entek Plus business unit, including new gearbox and melt-pump remanufacturing capabilities; and a new single-piece twin-screw design.

KraussMaffei Berstorff will show a compounding line featuring a ZE 60 A UTX twin-screw extruder fitted with the EasyClean module. This design includes improved features that permit a 40% reduction in cleaning time. The complete line is modular—based on pre-assembled components that can fit within a shipping container. This offers considerably reduced assembly time and cost at the plant site.

Modularity is also the hallmark of new compounding lines from Apex Engineering. A lot of the system is assembled off site, which slashes costs and schedules by 25-30%.

Unlike other types of reciprocating kneaders, which stroke once per shaft revolution, the new Tri-Volution Tri-Kneader is designed for three strokes per revolution. Its developer, B&P Process Equipment & Systems, says the machine combines the best features of typical kneaders with that of co-rotating, intermeshing compounding extruders. B&P evaluated differences between one to eight strokes per revolution. It found that three-strokes per revolution provided the best surface-area and multiplied interfaces to make a significant impact on dispersive/distributive mixing performance.

A triangular barrel is said to offer improved temperature control and ease of maintenance while facilitating placement of the multitude of pins in the barrel. The design opens the process window wide enough for nearly every type of compounding application, says B&P; a single machine reportedly can jump from carbon-black masterbatch to rigid PVC to PET with TiO2 with a limited amount of changeover.

Farrel Pomini is showcasing the CP Series II Compact Processor, a compounder designed specifically for top-quality dispersion of highly filled, highly pigmented materials. By allowing accurate, independent control of an integrated continuous mixer and extruder system, the CP reportedly provides greater control of product quality, processing versatility, and energy efficiency.

Coperion will exhibit its new Horizontal Fluidbed Separator (HFS), which offer fines separation for a wide variety of compounded products with a small footprint and minimal height requirement. Pelletizing is an abrasive step that sometimes results in dust or pellet deformation. When dusty or misshaped pellets are remelted for molding or extrusion, problems can crop up that may affect the final product. The HFS removes any dust or malformed pellets from the bulk materials prior to packaging or processing.

In the area of reclaim/recycling, a new PLC control for the Davis-Standard ram-stuffer extruder increases productivity for recyclers of low-bulk-density scrap such as films, fibers, and thermoformed sheet, says ADG Solutions, Davis’ exclusive North American distributor of reclaim and compounding equipment (adgs.net). The PLC control now available on the ram stuffer automatically monitors motor amps and eliminates the operator adjustments that had been needed to increase productivity.

The ram-stuffer extruder has a pneumatic reciprocating ram mounted at the feed throat, which stuffs material into the screw. The new PLC control adjusts the timing of the ram stroke according to variations in extrusion drive amperage caused by changes in material bulk density. Since the ram cycle governs the rate at which material is fed into the extruder, the automated PLC control ensures that production will continue at the maximum. The control system can be retrofitted on existing ram-stuffer extruders.

A ram-stuffer extruder can be installed in complete shredder-to-pelletizer recycling lines. The extruder feed throat is considerably larger than those found on standard extruders to prevent choking of light materials at the feed entrance. The throat is grooved to facilitate material conveyance and interaction with specially designed barrier screws.

Erema North America will show the 1514 TVEplus recycling system for the first time in the U.S. It is said to be the most advanced in Erema’s family of vented systems and is capable of throughputs of 2000 lb/hr. All models of the TVEplus are designed to recycle more highly contaminated material than less advanced systems. Tests of the TVEplus running heavily printed packaging film, for example, show an increase of approximately three times the efficiency at removing gases derived from ink, binding agents, other additives and incidental contaminating materials.

Recent innovations from Gamma Meccanica in Italy include the new Ecotronic control unit for its Compac line of reclaim systems for film, fiber, and sheet. The controller reportedly offers energy savings in excess of 40%. Also from Italy, Tecnova’s new Refil/1 is for in-line reclaiming of film scrap. The compact unit has a production rate up to 100 lb/hr and can handle a wide range of materials, including bioresins. Tecnova’s Mini 60 is a special grinder, die-face cutter, and cooling system designed to reprocess biodegradable materials as well as LDPE/HDPE/PP film.

WHAT ELSE TO SEE

A patent-pending backflush screen changer from PSI-Polymer Systems Inc. includes several new features for greater operator safety and improved performance. In its unique backflushing design, the contaminated screen packs are flushed and discharged through a port underneath the housing, creating a much cleaner and safer work environment for operators. The new design can process materials with extremely high levels of contamination.

Kreyenborg will also be displaying a newly designed backflush screen changer, but had no specific details to share at press time.

Gneuss’ Filtration Technology division will show new safety features and the option of an automatic ejector for the backflush material on RSFgenius rotary melt-filtration systems. Also, pressure transducers from Gneuss’ Measurement Technology division feature a new multipoint calibration system that allows for more precise measurement of lower pressures over large measuring ranges. For instance, an accuracy of 0.15% in an operating range of up to 100 bar is reportedly possible for a 0-1000 bar DAI pressure transmitter.

Also, Gneuss will debut a harder membrane coating option for its sensors that withstands very abrasive materials, such as wood/plastic composites (WPCs).

The EM-3c control from Invensys Euortherm is designed for small extruders but is packed with the features of the popular EM-3 PC-based extrusion control system. Its standard package can be used just for extruder temperature and pressure control or expanded to complete line control. Processors can save on installation costs and engineering time and expense due to the preconfigured screen package and standard control definitions.

A new hand-held computer tablet from Davis-Standard further improves mobility and access for complete extrusion system control. Called the DS-Tablet, this portable operator interface offers a wireless touchscreen option to processors using the EPIC III (iFIX) supervisory control system.

With a 10.4-in. screen and rugged design for industrial environments, this Windows-embedded tablet allows operators to access and control functions from outside typical OCS (Operator Control Station) locations. It also provides simultaneous remote viewing of the EPIC on an office PC or other mobile device using Internet Explorer.

Related Content

Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More