Faster Barrel Heating Makes for Speedier Startups

Swapping out OEM ceramic heater bands with special insulated TCS (Thermal Control Solution) heater bands saves California molder time and energy.

The work week at Norco Plastics used to begin at 3AM on Monday. Starting up operations after shutting down on Friday required an operator to arrive well before dawn and begin warming barrels on the custom molder’s 24 injection machines. Those presses, which skew heavy—up to 1800 tons, drew a huge amount of power during this initial startup, requiring the operator to stagger barrel warming.

“You couldn’t turn on all the heats at once,” explains John Williams, CEO at Norco, which is based in Chino, Calif. “It’s a lot of power draw at one time; you’d be amazed.” Williams says Norco eventually determined that it was more expensive to turn on all the heats at one time than it was to actually run the machines. These days, Norco is running seven days a week, but barrel heating time has been cut in half, thanks to the replacement of the machines’ OEM ceramic heater bands with TCS (Thermal Control Solution) heater bands from Rex Materials Inc.

“Our people can come in later, turn on more machines at one time, and they heat up a lot faster,” Williams says. Norco currently has the TCS system installed on 17 of its 24 machines and will be adding the heaters to two new presses on order. Williams says Norco considered retrofitting its machines with TCS heater bands around 10 years ago, but at the time found the cost too high. Back in the spring of 2017, energy consultant Bruce Blau once again piqued the company’s interest in the technology.

Working with Blau and the local utility, Southern California Edison (SCE), Norco was able to apply incentives to install the bands. SCE gave Norco a loan to pay for the equipment, and the molder paid the utility back at zero percent interest at a cost calculated based on savings. Payback on the $130,000 investment came in just a year and a half. SCE calculated Norco’s annual power savings to be 329,000 kWh.

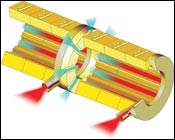

TCS heater bands from Rex Material embed heating elements within an insulated material just 1 in. from the barrel exterior.

In the TCS system, heating elements are contained within a vacuum-formed ceramic fiber material, which acts as an insulator. The heating elements are just one inch from the barrel’s exterior, and thanks to the insulating properties of the ceramic fiber, while internal temperatures might reach 1000 F, the external shell can be touched by hand. Rex Material says TCS systems can achieve temperatures as high as to 3000 F. Densities can range from 12 to 50 lb/ft3 by using a variety of different ceramic fiber types, fillers, and binder chemistries.

Getting Hot Faster, Staying Hot Longer

In addition to cutting startup barrel heating in half and reducing overall power consumption, Williams said Norco has enjoyed some other benefits from the TCS bands. When a job is being set up or finished, operators can turn the heaters off. “The TCS bands will retain the heat all day,” Williams says. “They’ll just sit there, and the heat will be in them. You come back, turn them on, and within in 10 min or so you can start back up.”

Because of that heat-retention capacity, Williams said Norco also learned that the TCS bands cannot be left on for risk of resin degradation. “Sometimes in the past we left our heaters on through a shift or overnight because we knew we were going to start the machine in the morning,” Williams says. “If you do that with that with these, they have a tendency to over-bake the material in the barrel.”

Finally, the insulative properties of the Pyrolite have made the environment around the machines and across the shop floor, cooler. “You can touch these, but it is hot,” Williams says. “You can put your hand on them, but you can’t keep it there for too long. With the old ones, whatever temperature they were at the barrel that was pretty much what they were on the outside.”

Williams says that in the two years Norco has utilized the TCS technology, the company has benefited from greater energy efficiency and process stability, while its operators have benefited from more sleep. “From our people’s perspective,” Williams says, “they don’t really look at the power savings as much as, ‘I don’t have to come in at 3 o’clock in the morning anymore.’”

Related Content

Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read MoreMachine-Side and Central Chiller Lines, Industry 4.0 Controls to Launch

Frigel will use K 2022 to showcase a number of developments in process cooling, including new and expanded lines of central and machine-side chillers, as well as advanced control platforms.

Read MoreLow-Flow Indicator Has Optional Flow Regulator

Burger & Brown's Smartflow Low Flow indicator monitors critical, restricted cooling paths such as mold cooling lines with bubblers or baffles.

Read MoreWisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreRead Next

Here's Another Way to Save Up To 70 percent in Barrel Heating/Cooling

Four months ago, we reported on a new induction barrel-heating system that promises to save up to 70% in energy costs (see Learn More). Here’s an update on another novel barrel heating—and cooling—system that boasts similarly large savings and has been out in the field long enough to build a track record.

Read MoreKeeping The Heat on The Barrel

Noncontact radiant heaters embedded in ceramic-fiber insulation save energy and keep heat from being lost into the plant environment.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)