For Better Warpage Simulation, Consider the Whole Molding Process

Which way will it warp, and how much? To get an accurate prediction, you have to look at the whole mold and the whole process, over several cycles.

Molders have used part-design based simulation tools for more than 20 years to obtain insight into molding behavior, even if that insight is just a hint of what might actually happen in their next molding trial. Few molders today would dare to build a mold without at least a few basic design simulations. However, molders are confronted with an awkward reality: Molds are still built without a known process, and if a process cannot be found during initial mold trials, tooling changes will be required, along with an additional molding trial. The result can be a significant amount of lost time.

This gap between simulation and reality is especially critical when predicting shrinkage and deformation. How can we virtually optimize the part, mold, and process in a way that the operating window for a new mold is intentionally larger and the parts from the first molding trial have a high probability of being acceptable?

Injection molding simulation is continuously improving, and alternatives are available to reduce the uncertainty associated with new molds. It is important that molders be aware of these new developments and be ready to change their perceptions of what successful simulation requires—and what it can deliver.

The time when simulation was used only to predict cavity filling is far behind us. Today we are now in the era where not only the cavity but the complete mold and molding process can be reproduced up to the last detail, including all molding stages (filling, solidification, part ejection, post-mold cooling, and the time between cycles). A significant advance in the technology is that the process can be simulated over multiple consecutive molding cycles, accounting for changes in mold temperature after startup.

We are now in the era of what may be called “Virtual Molding”: The outcome of a mold configuration and a process can be accurately optimized before the mold is built. It is no longer required to build the mold first, and then find a process, only to realize that something went wrong.

Embracing the Virtual Molding approach has an enormous impact on the workflow of injection molding companies. Molders have escalating pressure to deliver higher-quality products faster, and the need for simultaneous optimization of molds and processes in a virtual molding environment has never been greater. The ability to foresee what implications stem from a given decision pertaining to the mold or process substantially elevates the technical know-how of the design and development group, which is then available to engage with new products. Virtual Molding delivers increased competitiveness through knowledge: This is what will happen and here are the reasons why it will happen. Fewer assumptions and more calculations lead to a deeper understanding.

Using an example, this article illustrates some of the differences between a conventional injection molding approach and Virtual Molding. It focuses on the effect of each of approach specifically on part distortion after post-ejection cooling to ambient temperature.

A DEEPER UNDERSTANDING

In plastics, shrinkage is a consequence of local variations in polymer density, which depend strongly on temperature and pressure. Any variation in temperature or pressure in processing can have an influence on the local polymeric contraction and the free energy available between polymer molecules. Changes in molecular spacing and orientation, resulting in dimensional instability, are ongoing even after the part has ejected from the mold.

Therefore, to understand the root cause of warpage, there is one area of particular interest: the thermal gradient of the part at ejection. Since this example concerns a 10% glass-filled polycarbonate, you might ask, what about fiber orientation? This is a thick part, and it contains only 10% glass fiber; so, while fiber orientation is interesting, it’s not going to prevail in this product. The thermal gradient, however, is critical because it defines the existence of isolated areas of late solidification. These areas can be isolated from the packing pressure and will shrink more. Isolated areas of late solidification also contract more outside of the mold, where the part is unconstrained, pulling on the rest of the part and changing its shape.

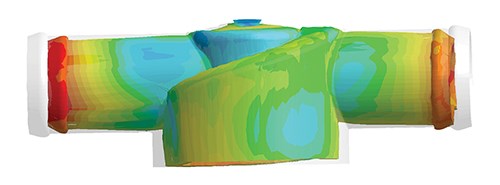

A 10% glass-filled PC was used to injection mold the product shown in Fig. 1. It was paramount to obtain a reliable warpage prediction because this product is part of an assembly. A conventional simulation approach using a uniform mold temperature was used to estimate the warpage. Only one molding cycle (filling, packing, cooling) was calculated, and the warpage result based on this assumption is shown in Fig. 2a.

What could be wrong with this assumption and what are the implications? It is customary for molders to think of mold temperature as a value, usually the same value as the setpoint on the water chiller. However, mold temperature is a function of time and position within the mold. The mold does not have a specific fixed temperature. It has a thermal gradient and this temperature map is constantly changing. Mold temperature is even affected by the time the mold remains open between cycles, where heat radiation towards the environment occurs.

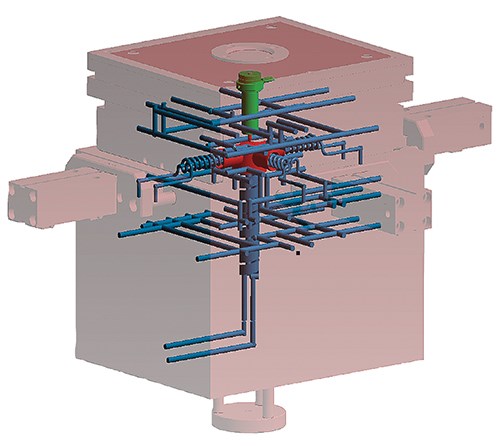

A second approach, which we call Virtual Molding, was used as a comparison. Instead of assuming a uniform mold temperature, the mold temperature was calculated as a function of time. To obtain this result—the total heat transfer between all mold components and the plastic—required calculating the heat transfer between cooling circuits and mold plates, the influence of high-conductivity mold inserts, the thermal effect of hot-runner manifolds, and even the heat transfer to the environment. Then, instead of considering only the cavity shape, the entire mold configuration (Fig. 3) is taken into account.

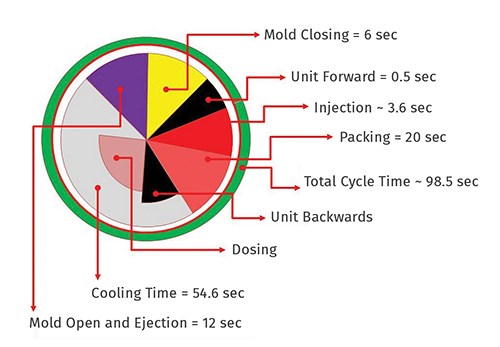

The molding process (Fig. 4) is considered in its entirety. This involves calculating not only the stages of filling, packing, and solidification, but also the mold opening sequence—the time required to open the mold, eject the part, and close the mold. In this particular case, the mold sequencing time is about 10% of the total cycle time.

During an actual molding trial, the first three to 10 parts may be discarded while the mold heats up. So, instead of simulating just one production cycle, several molding cycles are calculated consecutively, until the mold reaches a quasi-steady thermal state. This means it is still changing, but in a repeatable way from one cycle to the next. This is the stage where quality consistency is achieved in the molded parts.

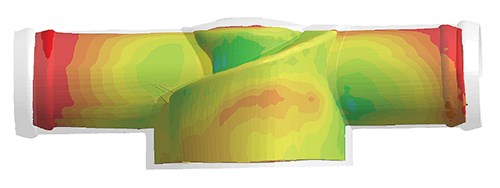

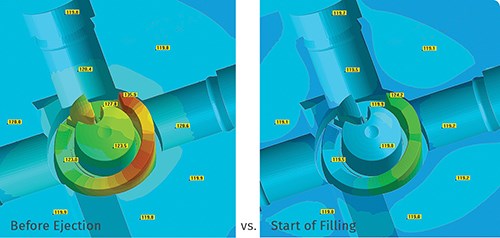

In Fig. 5, the thermal gradient of the movable mold half is shown after 10 molding cycles. The left image shows the temperature distribution just before ejection, and the right image shows the thermal gradient just before closing the mold again, after 18 seconds have elapsed. In this period of time, the mold remains open, radiating heat into the environment.

Two things are evident from Fig. 5. First, assuming a constant mold temperature as a boundary condition for this part would definitely seem to be a risky assumption. Not only is the mold temperature not constant over time, but it varies by about 15° C within the cavity and it is not at the water temperature. Furthermore, in the 18 seconds when the mold remains open, the temperature can change locally by up to 11° C, so in order to obtain the correct thermal gradient—and thus the energy available for molecular rearrangement and dimensional changes—it is imperative to include the actual mold and process, including mold sequencing times, within the calculation.

The warpage predicted using Virtual Molding is presented in Fig. 2b. The conditions to which the molded product are exposed are very different in both cases. The biggest difference is the ratio of polymer that solidified with packing pressure to that which solidified without packing pressure, which is a direct result of the difference in thermal energy available to produce local differences in molecular rearrangement. The assumption to use the single-cycle simulation approach, in this case, led to incorrect prediction of directional distortion.

This is a daily reality for the molding industry—questions about what assumptions to make, what results to trust, which direction will it warp, and how much. Answering those questions up front is the value that what we call Virtual Molding provides: You don’t have to make assumptions because you can trust your results and know which direction the part will warp and how much it will distort.

Using Virtual Molding to couple the heat and fluid flow calculations and generate the correct thermal gradient of the mold over multiple consecutive molding cycles, instead of assuming it is the same temperature everywhere and on every cycle, can lead to more accurate results. This approach allows molders to understand the root cause of the issues and to correct them before the mold is built.

Related Content

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreThe Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More