Four Key Markets Drive Material Advances At K 2010

Last fall’s K 2010 fair in Germany drew dozens of materials suppliers to show off hundreds of new products, aimed especially at packaging,medical, automotive, and electrical/electronics.

Last fall’s K 2010 fair in Germany drew dozens of materials suppliers to show off hundreds of new products, aimed especially at packaging,

medical, automotive, and electrical/electronics. TPEs and engineering thermoplastics—particularly nylons—were among the most numerous, though there were also significant introductions in polyolefins and styrenics. Here’s a quick rundown of news for North American processors. (Additional products were reported in our September show preview.)

RENEWABLE & SUSTAINABLE

Sustainability was the watchword at K, and one of its many meanings is basing plastics wholly or partly on renewable resources. Braskem of Brazil started up in late September its first plant to make polyethylene entirely from sugarcane ethanol. At least 70% of the 400-million-lb/yr capacity for “green PE” is spoken for by the likes of Procter and Gamble and Johnson & Johnson. Meanwhile, Braskem is planning a 60-million-lb/yr plant to make propylene monomer from sugarcane ethanol. From that monomer, Braskem plans to make “green PP.”

Telles, Lowell, Mass., launched its first sheet extrusion/thermoforming grade of Mirel bioplasic for non-alcoholic food contact. Mirel F3002 opens up new potential from frozen-food containers to hot cups and lids that can withstand microwave reheating and boiling water. Mirel is made by bacterial fermentation of starch.

Telles also says high-heat grades are coming that can withstand up to 123 C (253 F); and a dispensing-cup application in development will demonstrate the living-hinge capability of Mirel.

Kaneka Corp. of Japan (U.S. office in Pasadena, Texas) is developing a new biopolymer, PHBH (polyhydroxybutyrate-hexanoate), a copolyester derived from microbial digestion of plant oil. By varying the comonomer ratio, it can have properties from hard to soft, similar to PE or PP. Compared with PLA, it boasts higher heat and hydrolysis resistance, better moisture barrier, and improved biodgradability.

FKuR in Germany (U.S. office in Cedar Park, Texas, fkur.com) is working with Synbra in the Netherlands to develop high-heat PLA based on blends of the usual “right-handed” L-type PLA and its stereoisomer, “left-handed” D-type PLA. The resulting stereocomplex PLLA/PDLA has higher crystallinity and a melting point around 220 C/428 F, or 50° C/90° F higher than standard PLLA. FKuR intends to formulate new high-performance biocompounds with this engineered PLA. Its Bio-Flex line blends PLA with another biodegradable (but not biobased) copolyester. The K show saw the debut of Bio-Flex F 4110 for shrink films. It’s a compostable resin based 60% on renewable resources. Also new is Bio-Flex S 5630 for thermoforming and injection molding. It has a Vicat A temperature of 105 C.

Other partially biobased materials were announced at K:

•DSM (U.S. office in Evansville, Ind.) came out with five injection grades of its new EcoPaXX nylon 410. This unique high-temperature resin is based 70% on castor oil. It has a melting point of 250 C/482 F, rapid crystallization, low moisture absorption, and high chemical resistance. The first grades are unfilled or 30% and 50% glass, heat-stabilized; glass/mineral-filled; and halogen-free FR (UL 94V-0 at 0.75 mm).

•As reported in November, Solvay Advanced Polymers, Alpharetta, Ga., is working with Mitsubishi Gas Chemical of Japan to develop a 50% to 60% biobased, high-heat polyamide derived from castor oil. It will have a melting point of 280 to 290 C (536-554 F).

•The Green Line from EMS-Grivory (U.S. office in Sumter, S.C.), is a new series of 50% to 99% biobased specialty nylons. These include Grilamid 1S nylon 1010, Grilamid 2S nylon 610, Grilamid BTR clear amorphous nylon, and Grivory HT3 PPA.

•Evonik Degussa (U.S. office in Parsippany, N.J., degussa-hpp.com) is now offering its fully biobased Vestamid Terra DS nylon 1010 with 5% to 50% bamboo fiber. The company is also promoting wood/plastic composites based on Plexiglas acrylic instead of the usual polyolefins or PVC. Acrylic (offered here through Evonik Cyro LLC, Parsippany, N.J., cyro.com) provides good weatherability and colorability.

•Radici Group of Italy (U.S. office in Wadworth, Ohio) has commercialized nylon 610 based in part on castor oil. It’s called Radilon D.

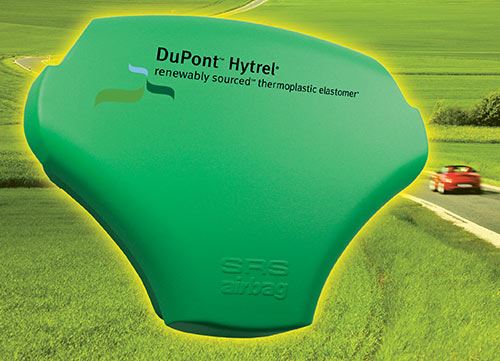

•DuPont Engineering Polymers, Wilmington, Del. (plastics.dupont.com), introduced the first renewably sourced TPE for airbag covers and drivers. Hytrel RS copolyester is based on PBT and a polyether soft segment derived from fermentation of nonfood biomass. It contains at least 35% renewable content.

•Kuraray of Japan (U.S. office in N.Y.C.) introduced Kuramiron EF “green” TPUs based on up to 40% renewable sources. These are part of the Kuramiron family, based on new production technology said to reduce lot-to-lot variation in melt visocosity and to decrease gel (fisheye) content.

•Merquinsa of Spain (U.S. office in Seabrook, N.H.) has added new grades of its Pearlthane Eco “Bio TPU” with up to 90% renewable content. One is Pearlthane Eco D12T95, a 95 Shore A grade said to have better hydrolysis resistance and lower density (1.15 g/cc) than a comparable standard TPU.

Recycle-containing plastics also lay claim to the sustainable label. Radici brought out the Radilon Green line of Radilon A nylon 66 and Radilon S nylon 6 in glass-filled grades with post-industrial recycle content from in-house manufacturing scrap of the Radici Group, including fibers operations. These are aimed particularly at automotive.

And SABIC Innovative Plastics, Pittsfield, Mass. (sabic-ip.com), has new PCR-based resins for electronics. They include Noryl Classico PCR, the first grade being Noryl PC RN0401 containing 20% recycled PS. It meets UL 94V-0 at 2 mm. Grades with up to 40% PCR are to appear in the next few months.

Cycoloy PCR resins are PC/ABS with 30% to 50% recycled PC from water bottles, CDs, and other sources. Filled and unfilled FR grades are available, such as Cycoloy RCM 6123 with 30% PCR, 94V-0 rating at 1.2 mm, and stiffness of 4.3 GPa (623,663 psi).

Lexan R9453 is PC with up to 30% PCR and nonhalogen FR rating of 94V-0 at 1.1 mm. Three new grades of Lexan EXL PC-silicone copolymer with PCR content of 10% to 80% join the initial grade launched at NPE ’09.

TPE ADVANCES

Apart from the biobased TPEs and TPUs noted above, there were several other entries in this fast-growing category. One was the first cyclic olefin copolymer (COC) TPE, from Topas Advanced Polymers, Florence, Ky. As reported last month, it’s very clear and flexible, with 89A hardness and ultimate elongation above 450%. It also boasts very good low-temperature properties.

The other brand-new TPE is Kurarity resin from Kuraray, based on PMMA and PnBA blocks. It has clarity similar to PMMA, good softness and flexibility, easy flow, and good adhesion to other polar plastics like PC, ABS, SAN, and PVC. Its polarity also provides good paintability. Its acrylic content gives it excellent weatherability and color stability. Kurarity (known developmentally as LA Polymer) can act as an impact modifier and flexibilizer for resins like PBT and PLA, also adding oil and abrasion resistance. It acts as a compatibilizer for PBT with ABS.

Kuraray also has added to its Septon family of hydrogenated styrenic block copolymers (HSBCs). Septon K is notable for its excellent bond to metal or glass without pretreatment.

Zeon (U.S. office in Louisville, Ky.) showed new Zeotherm 151-40D TPV for blow molding. Based on nylon 6 and crosslinked acrylate rubber, it’s aimed at automotive and boasts improved resistance to aggressive fluids. It withstands continuous use at -35 C to 150 C (-31 F to 302 F) and brief exposure to 175 C/347 F.

PolyOne GLS Thermoplastic Elastomers, McHenry, Ill., has extended the performance of SBC-type TPEs with its new OnFlex S high-temperature grades for seals in automotive and appliances. They show improved compression-set resistance at up to 150 C/302 F. PolyOne GLS also came out with injection molding grades of OnFlex HFFR 300 Series halogen-free FR TPEs for connectors and plugs. Reportedly unique in the market, they use the same technology as previously released OnFlex HFFR 300 extrusion grades for cables.

The big news from Kraton Polymers LLC, Houston, was the development of SBC-based compounds for slush-molded soft skins of auto instrument panels, airbag covers, armrests, consoles, and interior door trim. Developed in collaboration with Italian TPE compounder SO.F.TER., slush-molded SBC skins can be made on the same equipment as for PVC slush molding but reportedly are much more efficient, due to lower molding temperature and up to 30% thinner skins. They also save 30% to 40% in weight and have better aging properties and softer feel. The new compounds are said to be lower-cost alternatives to TPU and a performance upgrade over PVC at similar system cost.

Also unusual was the introduction by newly formed Styron LLC, Midland, Mich., formerly part of Dow Chemical, of the Inspire At-Press TPO System. Instead of stocking different TPOs for painted and unpainted automotive parts, this two-part system of PP and a masterbatch of rubber and fillers is said to add flexibility and reduce costs for molders.

Several developments from Kraiburg TPE (U.S. office in Duluth, Ga.) were reported in September, including improvements in its Hipex high-performance TPVs and new medical-grade Thermolast M HSBCs. Further new entries are scented grades of Thermolast K SBCs supplied as compounds or 50% masterbatches of essential oils—peppermint, vanilla, and apple.

AlphaGary Corp., Leominster, Mass., presented new Evoprene SBC-based TPEs. What’s claimed as a world first is a grade for pharmaceutical stoppers that provides outstanding sealing performance over a wide temperature range and is puncture resealable. It has been tested for biocompatibility according to USP Class VI and ISO 10993-5 and can be sterilized with conventional techniques. Also new is a compound developed for printing and laser marking, such as on inside seals of soft-drink caps. A new Adapted Evoprene COGEE grade reportedly allows ink-jet printing of photo-quality images without pretreatment or coextrusion/co-molding with PP. A new food-contact grade, Adapted Evoprene G, allows high-speed marking. And a new high-strength grade has tensile strength of 17 MPa (2465 psi), tear strength of 40 N/mm (5.7 lb/in.), and hardness of 50 A. (AlphaGary was recently acquired by Mexichem, a Mexican PVC producer.)

NYLONS GALORE

In addition to the products noted under the sustainability heading above, here’s what else was new in nylons:

•Arkema, Philadelphia, added a new high-impact grade (G300 HI) to its Rilsan Clear line of transparent nylons. It’s for molded eyeglass frames.

•DSM introduced Akulon Fuel Lock nylon 6 as a mono-material solution to reduce evaporative emissions from small fuel tanks for lawnmowers, off-road vehicles, and other small-engine devices. It boasts higher barrier than standard nylon 6, allowing thinner walls in monolayer tanks. Tests of a tank with 2-mm wall thickness showed emissions of less than 20% of the EPA limit.

•Another new eco-friendly product from DSM is a low-oligomer polyamide (LOPA)—a nylon 6 that reduces emissions of caprolactam monomer during extrusion of biaxially oriented film or coextrusion of films with nylon 6 outer layers. This grade contains only 0.10% residual monomer, vs. about 0.18% for a typical resin of RSV 3.0 viscosity. As much as half the residual lactam evaporates during extrusion, condensing into a fine powder that coats equipment, walls, and ceilings and can be inhaled by workers. A typical biax film line can release up to 15 tons of lactam per year.

•DSM released two new high-flow grades of nylon 46, Stanyl CR and Stanyl Highflow (30% to 50% glass or mineral/glass). Both are halogen-free FR grades.

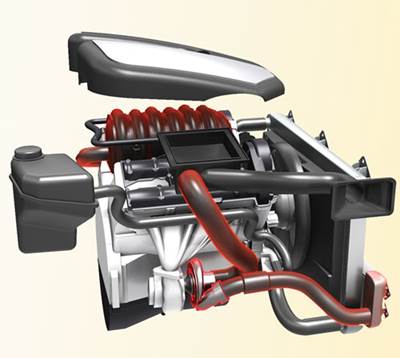

•DuPont added a sixth grade to its new Zytel Plus line of modified nylons that stay tougher longer in hot, aggressive auto underhood environments. Hot-oil resistance is a particular merit of these products, which include nylon 6 and 66 with special additives, as well as a new nylon copolymer. Zytel Plus 95G40DH1T is a new copolymer grade with 40% glass. It’s engineered to meet specs for aluminum mufflers and oil pans in stone impact and heat/oil aging.

•The “Shield Technology” used in Zytel Plus is also applied to two new Zytel HTN92 Series PPA resins with 35% and 45% glass for auto underhood uses. After 1000 hr at 230 C air-oven aging, their strength is said to be twice that of standard PPA and 20% to 25% higher than PPS.

•EMS-Grivory introduced long-carbon-fiber (LCF) grades of Grivory G partially aromatic, crystalline nylons and Grilamid L nylon 12. They’re for sporting goods, bicycle frames, and antistatic uses requiring high strength and toughness.

•New Grilamid TR 30 transparent, amorphous nylon with improved scratch and wear resistance resists nonpolar fluids in automotive and industrial applications such as filter housings, flow meters, or sight glasses.

•New for eyeglass frames are Grilamid TR 90 TL and TR 90 NZZ. The former allows filigree designs, owing to its high strength and stress-crack resistance. The latter has outstanding impact strength for sports applications.

•New second-generation Grilon TS nylon 6/66 copolymers have improved heat stability allowing 10° C higher continuous-use temperatures under the hood.

•Evonik has a new Vestamelt nylon copolymer that acts as an adhesion promoter between sheet metal and nylon in overmolded hybrid composites. Adhesion is so strong that a bond area of just 4 cm2 reportedly can support the weight of a heavy armchair. Vestamelt can be extrusion coated, electrostatically coated as a powder, or applied by coil coating.

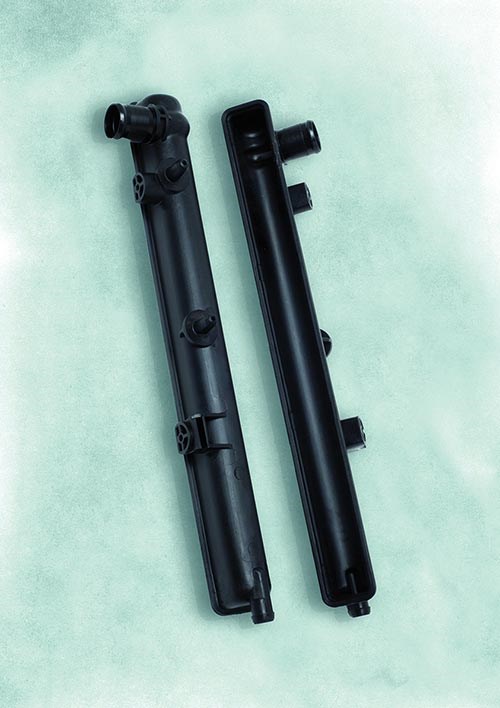

•Radici’s new Radilon A GF300 RKC is a glycol-resistant nylon 66 for car radiator end tanks. It contains some recycled fiber manufacturing scrap. Two related existing grades, which are new to the U.S. market, are Radilon A RV300 RKC, hydrolysis-resistant nylon 66 with 30% glass; and Radilon A GV HO 30P sw E4, a special nylon 66 billed as “top of the class” for auto cooling systems.

•Radilon A RV500RW 339 blk is a new 50% glass-filled nylon 66 said to beat other similar compounds in tensile strength, ultimate elongation, weld-line strength, and impact (wet or dry).

•Radilon A R350 HHR Blk is a 35%-glass nylon 66 with greatly improved heat-aging resistance. It withstands underhood exposure up to 200 C/392 F, suiting it to turbocharged engines.

•For blow molded turbo engine ducts, new Radilon A BMV200K 333 blk is a nylon 66 with improved heat aging (up to 200 C).

•Rhodia extended its TechnylStar high-flow nylon 66 technology from glass-filled grades to unfilled versions. The new ultra-high-flow unfilled grades allow lower molding temperatures, which reportedly can save up to 20% in energy and increase injection molding productivity by up to 15%.

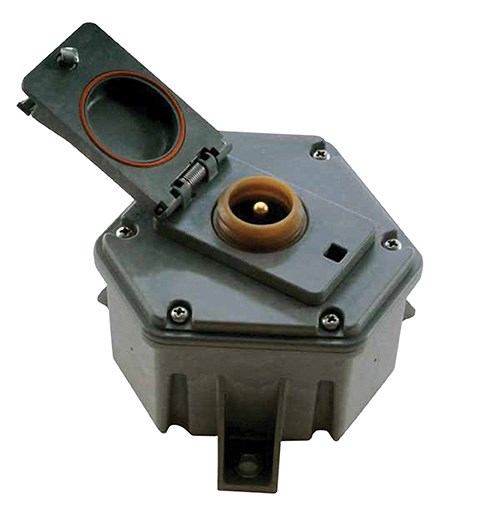

•Rhodia also launched halogen-free FR nylon 66 grades for photovoltaic (solar panel) components. They meet UL 5VA, 94V-0, and demanding UL F1 weatherability specs. Technyl A 60G1 V25 is designed for junction boxes and boasts “best-in-class” RTI. Technyl A 50H1 is particularly suited to thin-wall connectors.

•Solvay’s reformulated Ixef BXT 2000-0203 polyarylamide (MXD6 nylon) blow molding resin was recently approved by the EPA and California Air Resources Board (CARB) as an emissions barrier for three-layer fuel tanks used in lawnmowers, snow blowers, weed trimmers, generators, and other small off-road equipment. Approval reportedly lets OEMs use the material without costly, lengthy tank permeation testing.

OTHER ENGINEERING THERMOPLASTICS

DuPont introduced UV-stabilized Rynite PETs for photovoltaic module frames and components. They are a 35%-glass/mineral version for injection molding and a 40%-glass grade for injection or extrusion.

One member of DuPont’s new FG (Food Grade) family is Delrin FG400MTD, a metal-filled acetal for equipment used in food processing. Because it can be detected by metal sensors, it has been substited for stainless steel in food hoppers.

Radici introduced special hydrolysis-resistant PBT compounds, Raditer B RV300 KB and ERV300 TKB. Aimed at automotive and electrical/electronic parts exposed to high heat and humidity, they contain additives for laser marking. High flow suits them to thin-wall parts like connectors.

A second-generation injection molding grade of Topas COC from Topas Advanced Polymers offers a wider processing window and better surface quality without need of an external lubricant for injection-blow or stretch-blow molding. It is also being considered for extrusion blow molding.

Topas is launching a new range of COC/polyolefin blends, using the stiffness and heat resistance of COC to elevate PP into competition with polyetherimide, polysulfone, or polyethersulfone in steam-sterilizeable medical films and trays. Three TopasBlend PP alloys have HDTs of 140 to 160 C (284-320 F) at 66 psi. These non-transparent blends also have good dielectric properties, targeting replacement of PVDF in antenna insulation, for example. In development are COC/HDPE blends for steam-sterilizeable pharmaceutical bottles or caps.

Styron introduced Calibre 301-58 LT PC with high light transmission and high flow for LED applications. Opalescent, tinted, and UV-stabilized versions can be custom tailored. In addition, three developmental resins are aimed at thinner TV enclosures: XZ 94291.10 high-flow, transparent PC; XZ 92.696.00 high-heat, high-flow PC/ABS; and XZ 92.699.01 high-flow, high-modulus PC/PET/ABS.

SABIC Innovative Plastics has new Noryl GTX PPE/nylon alloys designed for larger auto body panels and tailgates. The 98 Series has up to 40% lower CLTE, which has been a limiting factor. The new grades also offer up to 50% higher stiffness without sacrificing impact strength.

SABIC beefed up its high-end range with new Extem UP alloys of thermoplastic polyimide (TPI) and PEEK. Amorphous TPI contributes high heat resistance and dimensional stability, while crystalline PEEK adds flowability and chemical resistance. The blend has one of the highest UL continuous-use temperature ratings for an unfilled thermoplastic. Continuous-use range is 150 to 250 C (302-482 F), and UL 746B RTI rating is 240 C. Stiffness and flex strength are up to five times greater than unfilled PEEK at 200 C, and CTE is up to 30% lower than unfilled PEEK. Applications include high-end connectors for military and aerospace, valves for the chemical industry, semiconductor chip trays, oil/gas industry parts, and very thin wire insulation. Two unfilled grades are available; glass-filled and lubricated are next.

Victrex Polymer Solutions, W. Conshohocken, Pa., introduced a companion to the easy-flow WG101 premium wear-resistant PEEK introduced a year ago. Newer Victrex WG102 is a standard-flow version with slightly higher strength, impact, and heat resistance.

POLYOLEFINS & STYRENICS

Dow Chemical, Midland, Mich. showed several new products:

•Three Clarilite HDPE and PP cap/closure resins are designed for excellent taste and odor and lightweighting.

•Five new high-flow PP copolymers for rigid packaging are designed to run faster and thinner and to provide good taste and odor and high clarity. They have MFRs of 70 or 100. One product allowed injection molding a thin-wall container at 30 C lower temperature for a 10% shorter cycle and 33% energy savings.

•Two new PPs are for non-pressure pipes. Developmental D151.01 is a low-shrink resin with excellent stiffness/impact balance and up to 10% faster line speed (50 m/min) for 20-mm OD pipe. Also new is Inspire 114 PP for faster extrusion due to its low viscosity and low melt temperature.

•New Dowlex 2377 PE-RT for industrial pipe. At 0.941 density and 0.55 MI, it offers long-term hydrostatic strength at high temperatures without crosslinking.

•An experimental PE for rotomolding large tanks is said to provide shorter oven times and higher impact strength.

•Sealution Peel Polymers are ready-to-use, single-pellet olefinic formulations for easy-open packaging. They eliminate on-line blending and can be used in blown and cast film with PE or PP substrates.

•Amplify TY Functional Polymers are maleic-anhydride (MAH) grafted polyolefins for use in PE-, PP-, and PS-based barrier film structures, as well as rigid packaging. They utilize Tymor PE-MAH grafting technology from Rohm and Haas (now part of Dow).

Styron announced its next-generation ESCR HIPS for refrigerator liners. XZ 94022 reportedly allows downgauging by 10% or more.

Total Petrochemicals (U.S. office in Houston) introduced products for refrigeration, including HIPS grades with improved ESCR and high gloss. Total also launched a new series of Lumicene PP random copolymers for injection molded food packaging, caps/closures, medical devices, and housewares. Five new grades have MFI of 10 to 110 plus good gloss and transparency.

Customers report 10% faster molding cycles with 110-MFI Lumicene than with a 70-MFI PP, while also obtaining higher stiffness and impact strength, allowing for downgauging of 4% to 8%.

Ticona, Florence, Ky., came out with GUR X 192 Macropowder of VHMW-PE. It can be sintered to produce porous parts for liquid and gas filtration with higher flow rates, lower pressure drops, and increased strength.

Related Content

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreLanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MorePrices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

Read MoreRead Next

K 2010 Preview, Materials Higher Performance, Better Processing, And Now Sustainability Share Spotlight at K

The K 2010 show will present new plastics materials for a wide range of industries, which makes it hard to generalize, but a few markets stand out prominently: packaging, medical, automotive, and electronic equipment.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More