Get Better at Quoting Injection Molded Parts: Part 4 of 4

This fourth and final installment focuses on labor, packaging, secondary operations and various assorted details.

When quoting a new job, some molders combine a single machine operator with their hourly machine rate. What if it takes 1-1/2 operators, or just half an operator, to perform the job in question? The argument that there is no such thing as a fraction of a person is incorrect. It is very common for one operator to tend to more than one machine. In fact, with smaller machines running fully automatic and the parts bulk packed in a corrugated box, one operator can often attend three or four machines.

Labor Costs

The job should be quoted based on the amount of labor required to perform the task—no more, no less. Think about what the operators have to do and how much time they have to do it in. Do they need to make their own boxes, degate the parts, sort parts from a family mold, assemble parts, fixture them, check critical dimensions, apply an adhesive label, etc.? Next, consider the cycle time of the mold and the number of parts ejected during each cycle. I often act out, or replicate what the operator needs to do, to see how long it takes. Keep in mind that labor cost on a small machine is typically a much larger percentage of the part cost then it is on a large machine. Therefore, be conservative (i.e., generous) when estimating the labor for a small machine.

The cost of an operator is not what he or she gets paid per hour—it’s considerably more. The cost of an operator must include items such as holiday pay, vacation pay, medical insurance, as well as the employer’s portion of the Social Security, Medicare, state, and federal unemployment taxes. The accounting department should calculate the labor rate to use during quoting. However, you might ask them if their calculation accounts for things such as lunch breaks, bathroom breaks, job training and possibly some shift overlap. It takes more than eight hours of labor to run a molding machine for eight hours.

It’s good practice to consider also the labor costs for the setup men, quality inspectors and material handlers. Some jobs take considerably more time to set up then others. Small MUD inserts can be set-up in minutes. Large molds with hydraulic cam pull, switches, and robots can take hours. Some jobs require a considerable amount of part inspection and documentation, such as automotive and medical jobs. Other jobs only require the operator to know what flash and a short shot look like. Some jobs generate a lot of regrind, such as with cold runners in a three-plate mold. Others don’t generate any regrind at all because they are specified “virgin-only.” If the job you are quoting takes a long time to set up, requires a lot of inspection, or generates a lot of regrind, those associative labor costs should be added to the part quote.

Packaging Costs

Determining the correct packing requires two things: 1) Asking the customer exactly how he wants his parts packaged--don’t assume you know what he wants—and 2) determining the best box type and size that maximize the box quantity while protecting the parts from warpage or damage, and is not too heavy for an operator to lift and place on the top row of a pallet. Using your CAD software program is a great way to help make this determination.

Ask customers exactly how they wants their parts packaged.

The word “box” is a generic term. The number of available variations in size, construction and physical properties can make your head spin. It is important to know a few basic things about boxes to prevent all sorts of problems. The first thing you need to know is that they are not cardboard boxes. Cardboard boxes are used to package breakfast cereal and cake mixes. You want corrugated boxes because they have a corrugated inner layer for strength and protection.

The most common type of box is called a regular slotted container, or RSC. The top and bottom outer flaps of this type of box meet at the center when folded over, so they can be neatly taped or stapled shut. The inner flaps are shorter and do not meet in the center. This type of box is the least expensive because it generates very little waste when manufactured. Box sizes are specified by length, width, and depth—in that order. These are inside dimensions—and that matters. You also need to know the outside dimensions of the box to make sure they don’t hang over the edge of the pallet. In fact, try to have a minimum of an inch or two of space between the boxes and the outer edges of the pallet. Otherwise, the boxes will get damaged when loaded on a truck and during transit.

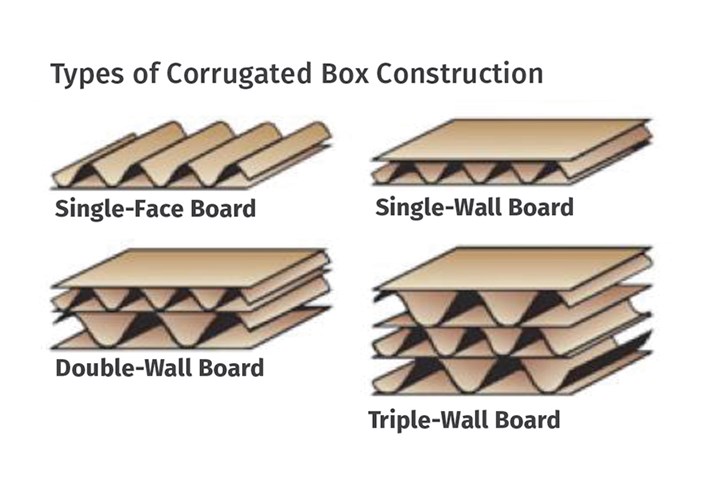

FIG 1 Four basic types of corrugated box constructions. Most of the time single-wall construction will suit your purposes.

There are four basic types of corrugated box construction, as shown in Fig. 1. Most of the time, single-wall construction will suit your purposes. On occasion, a double-wall box may be required.

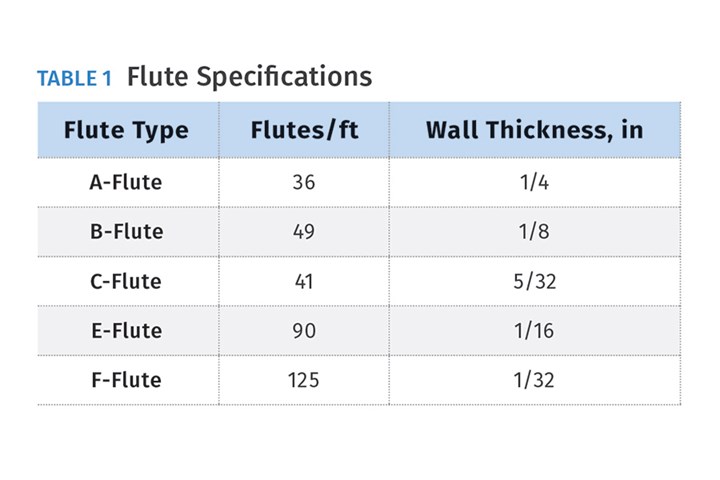

The wavy corrugated portions of the box (shown in Fig. 1), are called flutes or profiles. The five most common flute styles are pictured in Fig. 2 and described in Table 1. C-Flute is the most common type of RSC box. E-Flute and F-Flute are commonly used in small retail boxes that have detailed graphics printed on the outside, because the more flutes you have per foot, the shallower the waves or ripples on the outer surface.

FIG 2 The most five common flute styles. C-Flute is the most common type of RSC box.

While having a lot of flutes per foot is better for printing, fewer flutes/ft generally have better vertical compression strength. Compression strength is another reason why the length, width, and height dimensions are important. You never want a box to lay on its side. It was designed and strength-rated to be laid on its bottom for stacking. If you stack boxes on their side instead of their bottom, you will not have the same stacking strength, because the flutes will then be oriented horizontally instead of vertically.

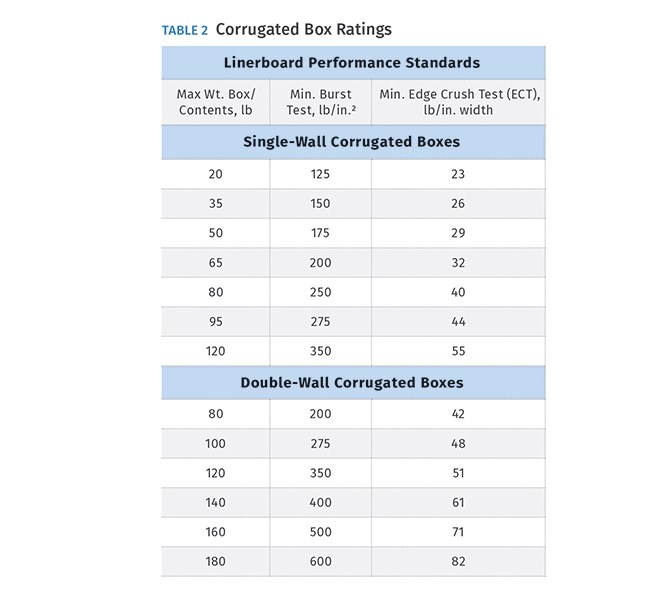

The two most common measurements or ratings of box strength are burst strength (also known as the Mullen test) and ECT (which stands for edge crush test). Burst strength is useful for predicting how a box will withstand being dropped, jostled, or otherwise subjected to rough treatment. The edge crush test is a way of predicting the compression strength of a corrugated box. It was developed to be a more direct indicator of a box's ability to hold a static load over time. This is also called the stacking strength and it is applicable to most molders who put their finished products on pallets. If the bottom row of boxes on a pallet collapses, especially during humid weather, the ECT rating was not high enough.

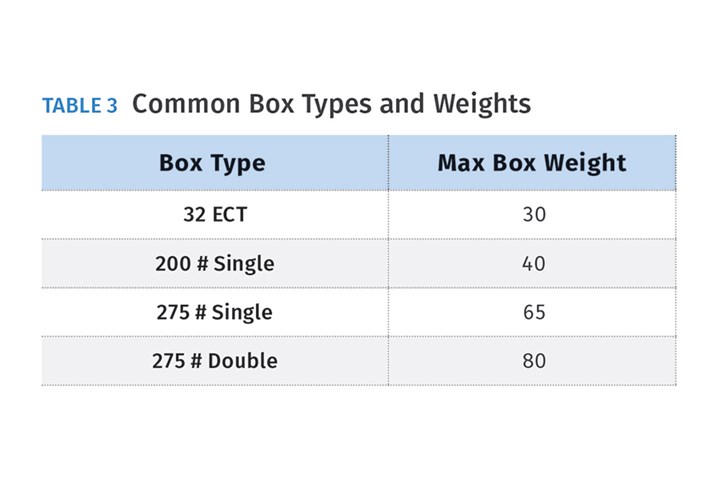

Table 2 lists the burst strength and ECT ratings of single- and double-wall boxes. Table 3 lists the most commonly used box types and their suggested maximum content weight. Box ratings can vary from manufacturer to manufacturer depending on the paper they use. The bottom of the box will have a round certificate stamp that specifies the type of box as well as the suggested maximum load.

Always try to select a box with the same length, width and height. These are called cubed boxes. They are the least expensive. For example, a 12 in. × 12 in. × 12 in. box has 1728 in.3 of space and costs about 85ȼ. An 8 × 8 × 24 in. box only has 1536 in.3 of space but can cost twice as much.

Cubed boxes are the least expensive.

Let’s assume the boxes are small—say 6 in.3. Most skids are stacked just under 8 ft high—a few inches shorter than the height of the inside of a tractor trailer. This particular skid will therefore have 16 vertical rows. I guarantee that without some method of keeping the stack of boxes intact, they will scatter all over the floor when the forklift goes to move the pallet. How do you prevent that from happening? Placing 40 × 48 in. corrugated skid pads between the layers of boxes, as well as corner guards, reinforced banding and shrink wrap, are some commonly used methods—all of which have associated material and labor costs.

I recall reviewing a fellow engineer’s part quote and telling him the packaging cost was way off. When he asked why, I informed him that this part is being shipped to one of the big-box stores. These retailers have stack-height requirements based on the height of their shelves. The boxes could only be stacked two rows high—a third of what could otherwise fit on a wooden pallet. A wooden pallet costs about $5. If you can only get two rows on the pallet, that adds a significant cost to each box.

An 8 in. × 8 in. × 2 mil polybag will cost about 3ȼ. An 8 in. × 8 in. × 4 mil reclosable (zippered) polybag will cost about $1. If the bag needs to be gusseted, shielded, printed with a white block, or die-cut for retail markets, that cost is going to be even higher. Don’t forget to include in your quote the cost of any cardboard dividers, tissue paper, foam, newsprint, or other packaging materials required to protect the parts.

If the corrugated master carton is a custom size, or if there are custom chipboard boxes inside the master carton, these will require getting firm quotes from a container company. Usually there will be a one-time die charge, which is often somewhat expensive. If any of the packaging, including any adhesive labels or instruction sheets, must be in color, those can also be expensive. It is not unrealistic for the total packaging costs to exceed the cost of the molded parts. With custom packaging items like these, it is best to ask the customer to pay for them up-front. If the estimated sales volume doesn’t come to fruition, you don’t want to get stuck with a lot of expensive inventory you will never be able to use.

Costs of Secondary Operations

In order to be competitive, most molders today must offer a variety of additional services. Commonly, that means secondary operations such as assembly, ultrasonic welding, hot stamping, pad printing, heat staking or swaging, riveting and machining. Once again, you have to think about what the secondary operator needs to do. The only difference is that a secondary operator is not motivated by a mold repeatedly opening at a specific time interval. Therefore, be a little more generous with your estimation.

Most secondary operations require component costs in addition to the labor cost. Some of these costs are one-time costs, such as for a fixture, stamping die, or custom ultrasonic welding horn. Other costs are consumables and are based on the production quantity, such as threaded inserts, hot-stamping foil, pad-printing inks or adhesives. All secondary operations have associated setup, debug, and teardown costs. This last item is commonly forgotten when quoting—and that’s a big mistake. Debugging costs can be staggering in both man-hours and scrap generation.

Quality Considerations

The initial hurdle of any new mold is getting samples approved. Sometimes that’s nothing more than putting a few parts in a box and sending them to the customer. Other times it can be quite involved—and expensive. Is an ISIR (Initial Sample Inspection Report), FAIR (First Article Inspection Report), DOE (Design of Experiments), PPAP (Production part Approval Process), Cp or CpK Study or other procedure required? How many critical dimensions are specified? How tight are the tolerances? Are any inspection fixtures or gauges required? How often do they need to be inspected during production? These are the types of questions you need to ask so that you can quote the part properly.

Other (not Trivial) Considerations

There are a few other items to consider when quoting a new job. If the parts are large, they will take up a lot of floorspace in the warehouse before they are shipped out. Floorspace is valuable—not just in terms of having enough room to move around, but in operating cost. A 20,000 ft2 building costs more to build, heat and maintain than a 10,000 ft2 building. Therefore, there is a $/ft2 cost associated with floorspace. Additionally, if room is tight, the warehousemen often double-stack the pallets—putting one on top of another. In order to prevent damage to the bottom layer of boxes, you need to go back and read the section on ECT box strength. You might need to specify a stronger, more expensive box.

Are you quoting a job for an existing customer? If so, that’s an indication that it is pleased with your company’s abilities, the quality of previously molded parts, engineering support and customer service. That’s worth a little something. If you are quoting a job for a new customer, you need to use a sharp pencil to get that first order.

The best customer is a knowledgeable one. It supplies you with all the information needed to accurately quote a part. Other customers email you a solid CAD model and say they need 10,000 a month in nylon 66. For this type of customer, submit a part-cost estimation—not a firm part quote. Until you get more information, such as what the part will be used for, what the packaging requirements are, what the aesthetic requirements are—as well as receiving a 2D drawing defining the critical dimensions—you really don’t know what is required. That can lead to a lot of surprises later on and surprises are rarely good.

Most customers want to know their part price FOB their facility—not your dock. Try to avoid providing that. The freight or shipping costs of a full truckload versus LTL (less than truckload) are considerably different. If you must quote the parts FOB the customer’s facility, have the shipping department get firm quotes for both a full truckload and LTL. Have a separate line item on your quotation for the estimated freight cost, because they frequently change.

A significant cost that is often neglected is mold maintenance. Most molders do not charge for it, especially if they built the mold or had someone build it for them. It’s an unwritten rule that the molder will properly maintain a customer’s tooling while in their care. In addition to molds needing a good cleaning after a specific number of cycles, many of the components will wear over time and need to be adjusted or replaced.

There is no way to accurately predict the longevity of a mold and the future costs associated with keeping it production-ready. Just because the mold may have had an initial rating, such as class 102, which supposedly means it is able to produce 1 million cycles, doesn’t mean that it will do so without some unforeseen costs. A person skilled in the art of molding knows that a simple two-plate mold with no cam action, lifters or shifted parting line will cost very little to maintain, while more complex tools, can drain your profits quickly. This understanding needs to be accounted for in the part quote.

Mold maintenance and repair costs can drain your profits.

While most molders want long-running jobs, not all jobs are like that. Since setup and startup costs are so expensive for short runs, it’s a good idea to specify a minimum order quantity or run time—somewhere between a full shift and a full week.

I have never liked the standard verbiage, “Prices held for 90 days.” Who picked that number? What happens on the 91st day? Does anyone ever increase their prices then? I prefer to use the phrase, “Prices held until costs beyond our control increase.” That phrase protects the molder from dwindling profits and gives the customer notification that prices may change in the future—as they often should.

Most quotation templates specify a generic lead time of three to four weeks ARO (After Receipt of Order). Many types and grades of molding material are not stocked by suppliers and can take six weeks or more to compound. It won’t look good if you make a promise you can’t keep.

Payment terms, such as 1% 10, Net 30, should also be considered. Discuss what terms should be used with the accounting department for potential customers. Do you want to offer a discount for paying early? Is there a penalty if invoices are paid late? Do you want a percentage upfront from a small customer who has no track record?

Lastly, don’t forget to apply a salesperson’s commission or mold amortization, if applicable.

Quoting an injection molded part is not difficult. It’s just time-consuming. If you don’t take the time to consider all the aspects of each request, you could be setting yourself up for a loss—either by losing money if you get the job, or by not getting the job at all.

About the Author: Jim Fattori is a third-generation molder with more than 40 years of experience in engineering and project management for custom and captive molders. He is the founder of Injection Mold Consulting LLC in Pennsylvania. Contact: jim@injectionmoldconsulting.com;

injectionmoldconsulting.com

Related Content

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreRead Next

Get Better at Quoting Injection Molded Parts: Part 3

Follow these detailed tips to get the jobs you want. This installment focuses on the mold and the molding machine.

Read MoreGet Better at Quoting Injection Molded Parts: Part 2

Follow these detailed tips to get you the injection molding jobs you want. Here we factor in the costs of scrap and regrind, along with energy and certain additives.

Read MoreGet Better at Quoting Injection Molded Parts: Part 1

Follow these detailed tips to get you the jobs you want. This installment focuses on the various raw material aspects of quoting.

Read More