Giving the ‘Royal’ Treatment in PET Packaging

In the U.S. for just seven years, Royal Interpack is emerging as a growing, innovative, customer-centric supplier of food packaging.

Royal Interpack Group certainly has accomplished a lot in a relatively short period of time. A member of Royal Holdings in Thailand, the family-owned-and-operated business launched in 2000, in a small plant with two vacuum-forming machines and a handful of employees making PET clamshells for fruit and produce.

Just eight years later, it moved to a 35-acre site in Chonburi, Thailand, an operation that brings under one roof post-consumer PET recycling, PET sheet extrusion and thermoforming of rigid packaging serving produce, bakery, food processors, fast food, and deli markets. Today, the Thailand operation employs more than 100 people and reprocesses post-consumer PET bottles collected from Asia, Australia, and other regions at a rate of about 20 million lb∕yr.

In 2012, When Royal set its sights on the North American market, it opened a 150,000 ft² plant in Riverside, Calif. Initially, this plant was divided between manufacturing and warehousing. Now it’s entirely production, with another 100,000 ft² in a nearby warehouse. And just three years after the Riverside startup, Royal expanded into the Midwest, investing nearly $12 million in a 40,000 ft² plant leased in Anderson, Ind., which produces more than 20 million lb a year of clamshell containers for fruits, vegetables, bakery, deli and other food-service items that are sold to processors, packers and distributors. And just a month ago, Royal opened a brand-new 130,000 ft² plant in Whitestown, Ind.

States Kunal Sidhpura, director of operations for the company’s North American business. “Initially we were exporting packages from Thailand before we opened the California plant. Our core values are to provide products made to extremely high quality standards, to focus on the needs of the customer, and to respond quickly. So, we decided we needed a footprint in the U.S., because that’s where our customers needed us to be.”

The Riverside operation houses four sheet lines furnished by German machine builder Diamat Maschinenbau, with a fifth one planned. The machines have 125-mm single screws that run primarily PET at rates above 2600 lb∕hr. Diamat supplies these lines on a turnkey basis, equipping them with its own sheet dies and Nordson backflush screen changers, as well as drying, crystallizing, and conveying systems from Motan. Sheet is run at widths from 20 to 62 in. at thicknesses from 10 to 40 mil. Royal runs reclaimed PET sourced from its Thailand operation in an A-B-A coex structure.

In California, Royal has 13 thermoforming lines that consist of seven “Asian-style,” smaller-format presses—advantageous because they permit utilization of more economical tooling—along with six faster-cycling thermoformers from Europe. One of these is equipped with a robot, which erects the packing box, fills it with products, tapes it, and loads on it on a pallet,

On the way to Riverside is a 52-in.-wide Lyle thermoformer, and Royal is adding extra extrusion capacity to accommodate it—set up in a rather innovative way. Two 125-mm extruders will share a single-layer die to create a line capable of running more than 4400 lb∕hr.

The new plant in Indiana is another reflection of Royal’s credo to “be where the customer needs us.” Royal quickly outgrew its original 40,00 ft² plant in Anderson, necessitating the need for bigger digs. “A location in the Midwest where we can produce our entire product line is a vital part of our strategy to be fast and responsive,” says Sidhpura. “From Indiana, you can reach 70% of the U.S. in one-day’s highway travel,” he notes.

Royal’s model is to have the same equipment set up in all its facilities, including extrusion, thermoforming and auxiliary equipment, accordingly Sidhpura. “This allows us to ship tools around all of our facilities depending on what the customer needs and when.” Royal runs its extrusion and thermoforming lines on a 24∕7 basis.

There is currently one 125-mm Diamat coextrusion line running in Indiana, with two more on order, as well as five Asian thermoformers, also equipped with economical tooling. Ultimately, Royal expects to add robotics to its Indiana thermoforming operation. States Sidhpura, “We utilize technology to improve efficiency and to minimize waste. In the long run, we feel that the best way to remain competitive is to automate.” Royal is also investigating an investment in larger-width thermoforming technology in the Hoosier state.

In terms of its overall production capacity in the U.S., Sidhpura considers Royal to be “mid-size.” Yet the firm’s business strategy to be nimble and responsive resembles more closely the mindset of a smaller company. “Over the year, we have picked up small projects, and these have led to large projects because of the way we have served the customer.”

Sidhpura continues, “We pick up small projects that lead to large projects. Larger competitors often won’t consider a project unless there is a minimum commitment. Consolidation in the industry can lead to an erosion in customer service. We’ve acquired business from big players. We’ve had customers come to us, stating, ‘We’re in a bind, we need something quickly, can you help us out?’ And we do.”

Big on Collaboration

Royal Interpack’s ability to replicate technology platforms across plants around the world requires it to align closely with a select set group of suppliers. On the extrusion side, as noted, it relies on Diamat for turnkey lines that include some auxiliaries. For cooling, it has been working with Frigel to provide advanced process-cooling methods, first in California, then replicated in Indiana.

When Royal started out in California, recalls Juan Alvarez, the firm’s technology director, it was relying on air-cooled chillers as the only process-cooling source in the plant. This proved ineffective, so the company began working with Frigel to come up with a system that would achieve optimal control of water temperatures and flows to achieve a three-pronged objective: effortlessly match water temperature and flow to the characteristics of any given process and product; increase throughput of extruded sheet for thermoforming; and reduce the amount of energy consumed in extrusion and thermoforming, consistent with Royal Interpack’s commitment to sustainability.

Frigel began with an extensive analysis of the extrusion and forming processes and associated cooling temperatures and requirements. From there it designed and implemented an integrated cooling system that eliminated the air-cooled chillers altogether. The new system features components tailored to each process. Each sheet extrusion line, for example, uses one dual-zone Microgel RCD and one single-zone Microgel RCM unit; both are chiller∕temperature-control unit (TCU) combinations. Positioned next to each line to cool the roll stack, the Microgel units supply the precise temperatures, turbulent water flow, and pressure needed for each production run.

Each of the 13 thermoforming lines in California uses a single-zone Microgel unit to deliver the same level of control as that achieved on the extrusion lines. Plantwide, three closed-loop Ecodry central adiabatic coolers deliver process-cooling water to the machine-side Microgel units used in both processes. Frigel monitors each microprocessor controlled Ecodry unit to ensure optimal efficiency and ease of routine maintenance.

Alvarez says the Frigel system provides control over process cooling—including temperatures and flows—where none existed before. As a result, he says, the processor has been able to leverage the full capacity of its extruders by boosting throughput by as much as 15%. Machine-side control also eliminated the need to use a heat exchanger to reheat chilled water supplied previously by an air-cooled chiller.

Moreover, Royal Interpack now consistently delivers process-cooling water to the thermoforming lines at the temperatures, flows, and pressures needed, says Alvarez. This means there is no wasted energy, since air-cooled chillers often provide no temperature control and supply water at only one temperature and flow rate. The new system achieves even more energy savings because it uses ambient air to cool process water to save energy via “free cooling,” which means there is no need for chillers to meet cooling loads when ambient conditions permit, Alvarez points out.

“We can also monitor process data remotely to see how equipment is running, to catch mishaps,” Alvarez states. The control system is also integrated with the Motan auxiliaries for total line monitoring and data gathering.

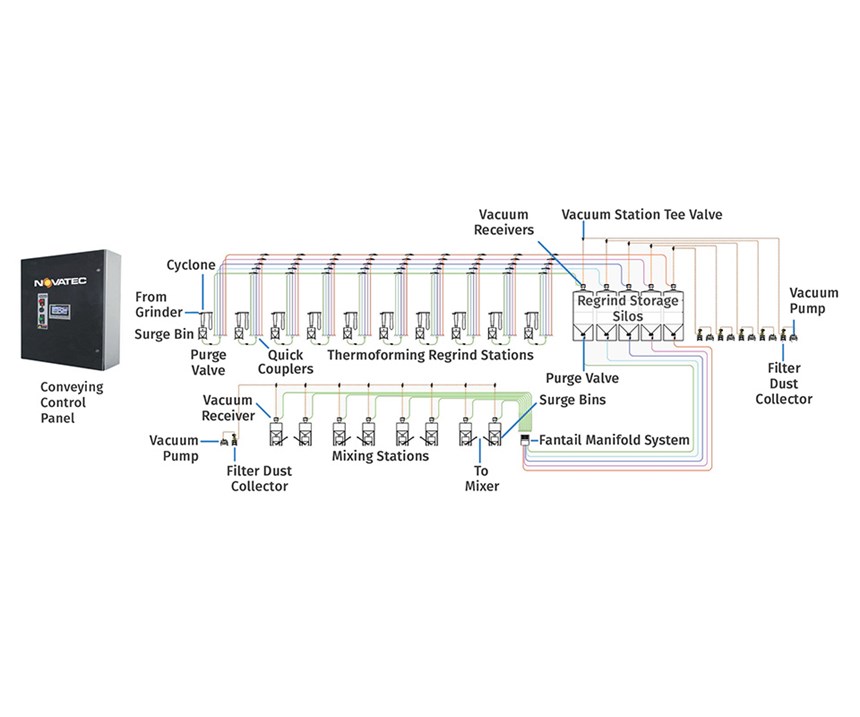

More recently, Royal worked with Novatec to engineer a central conveying system that automates the collection of sheet edge trim and thermoforming skeleton scrap. The first such system will be installed in the California plant; then once it’s proven out it will be supplied to the Indiana facility as well. Extrusion and thermoforming scrap is conveyed to buffer silos, then back into the process as needed. Sidhpura says this is a more efficient way to handle scrap then to feed it out of bulk bags, which tend to rip. It is also modular, so the system can be expanded in increments as the processor increases its extrusion and thermoforming capacity.

Royal Interpack collaborates with local tool shops all over the world, resulting in delivery of 3D tool designs within 48 hr, prototype parts in a week, and production parts in a one-up cavity in two weeks.

Its collaborative efforts also extend beyond its supply chain to the customer and beyond. Says Sidhpura, “We work not only with our customers on new designs, but at the retail level, too.” In one instance, Sidhpura said the firm worked with an undisclosed retailer on a new package design that converted a round container to a square package, improving the retailer’s shelf utilization and the visibility of the product, which had been obstructed by a bulky tamper-evident seal. The project started with cut fruit and is now being used for salad packaging and deli platters as well.

Related Content

Back in the Family Business

In its 45th year, Precision Molded Plastics has carved out a technology and market niche, growing not just when opportunities arise but when they make sense, after its leader changed careers to keep the family business from changing hands.

Read MoreGeneration Gap? Not at Packaging Personified

Started at a kitchen table and now in its third-generation of family involvement, this vertically integrated supplier of flexible packaging traces its success to closely aligning with customers and continually investing in new technology across its films, printing and converting operations.

Read MoreInside the Florida Recycler Gearing Up to Take on Scrap at NPE2024

Hundreds of tons of demonstration products will be created at NPE2024 next spring. Commercial Plastics Recycling strives to recycle all of it.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)