Having Output Problems? Check Your Feed-Port Design

With an extruder, like all other devices, “it can’t come out unless it goes in first.” That’s the first thing I remember when I am asked to figure out why an extruder is performing below expectations.

With an extruder, like all other devices, “it can’t come out unless it goes in first.” That’s the first thing I remember when I am asked to figure out why an extruder is performing below expectations. Unfortunately, many extruders are actually designed to place limits on output. I am not referring to poor screw design, but something perhaps even more fundamental: bad feed-port geometry.

An extruder is, after all, a pump, and to optimize the performance of any kind of pump you need to have an adequate flow of material coming to the device, and an adequate entryway into the device itself. It sounds simple, and relatively speaking, it is. Yet feeding is one of those seemingly mundane details that if overlooked can cause issues from the moment you turn the machine on.

And it's not just an issue for old machines; even today I see spanking new extruders where less-than-optimum feed-port geometry is used in an effort to reduce manufacturing cost.

INLET DESIGN IS KEY

So what makes for optimum inlet design? Way back when, many inlets were nothing more than a round hole. That design in itself restricted the feed, but to make matters worse this hole was usually situated atop the start of the screw flights or “pocket.” Keep in mind that the pocket of the screw cannot convey material forward until the pushing side of the flight takes on a pitch. As a result, almost one-third of a round opening can be blocked for part of each screw revolution! This obviously limits output and can result in unstable feeding.

That problem was largely corrected when machine builders went to rectangular or oblong feed ports, where one full flight is always open under the hopper to accept infeed material.

In order to be carried forward, the feed material must be contained between the screw and the barrel wall. Consequently, there is little forwarding going on under the actual feed opening. Flow occurs only after the screw conveys the polymer in a radial direction, containing it between the screw channel and barrel wall. Just like any other pump, this process can be assisted by a little head pressure to push the polymer down into the gap formed by the screw channel and the barrel wall.

If you have ever watched a hopper empty, you have seen that the extruder output drops significantly when the feed level falls below a certain point. That’s because there is too little pressure on the remaining material. As a result, the material tends to “float” on the screw rather than be conveyed into the closed space formed by the screw channel and the barrel wall.

Also, the faster the screw turns, the more it tends to lift the material as the flight enters the throat opening. Unless there is some pressure to help gravity, the feed material may not have time to fall into the open channel for a complete fill. This is often the case for an extruder that has declining or flat specific output above a certain screw speed.

The greater the downward pressure exerted on the feed material the better the feed rate. This is particularly true when bulk density is reduced by the introduction of regrind. The pressure we are talking about is only a few psig, and it usually can be accomplished with 18 to 24 in. of material over the screw. However, any obstruction or geometric change that reduces that pressure also reduces the feed rate.

The accompanying illustration shows some examples of geometry changes that can affect output, compared with the proper design of a feed entry. Figure A is the proper design, where the hopper exit to the feed throat is the same size as the rectangular feed opening, and the feed-throat opening width is exactly the same as the barrel bore and the length is 1.5 times the barrel bore.

The feed entry should retain those dimensions for a height of at least 18 in. and preferably 24 in. above the screw to ensure some column pressure on the feed material at the screw.

Figure B shows a hopper exit that is smaller than the feed-throat opening, which creates a restriction to flow into the screw and reduces pressure on the material entering the feed throat.

Figure C shows a device mounted over the feed throat opening that restricts the flow and reduces the pressure. In this case it is an undersized magnet pack, but it can be any form of restriction such as a split hopper entry, a poorly fitting slide gate, or any minor geometry change that would restrict flow.

Figure D shows a side feeder that protrudes into the flow path in the area necessary to develop the pressure over the screw. Depending on its geometry, it can have a significant effect on the feed pressure and resultant output. Side-feed devices should either not protrude into the feed opening or be raised at least 24 in. above the screw.

If you think of the polymer flow into the screw like the flow of water into a pump, it becomes obvious which items and geometries will affect the feed rate.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

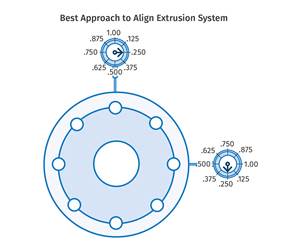

Extruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.jpg;width=70;height=70;mode=crop)