Heat Deflection Temperature vs. Dynamic Mechanical Analysis (Part 3)

DMA provides a rich and detailed picture of polymer performance, and it can be challenging to understand all the things that we can and should know about our materials. But the fact that it may be hard does not mean that it should not be attempted.

Since we have demonstrated the lack of detail regarding elevated-temperature performance provided by the heat-deflection temperature (HDT) test in the first two parts of this series, one may wonder why it is that we continue to perform it and publish the results. During NPE2018 I gave a short presentation entitled “Never Use HDT Values Again.” But perhaps a better objective would be to never perform HDT tests again. We are so accustomed to a particular way of doing things, that as long as someone is generating the test results, people will continue to use them. But to what end?

Periodically, the question about the utility of HDT comes up in an online discussion and sometimes specific questions are asked about comparing HDT to dynamic mechanical analysis (DMA). Some of the answers are curious. I saw one response that preferred HDT “because there is a published method for it.” In this individual’s mind, the fact that a method exists for conducting a test is the foundation for judging the utility of that test. Aside from the fact that there are multiple methods published for DMA, it may be useful to look briefly at the history of HDT methods.

The ASTM method known as D 648 was first published in 1941. Generally, the lower the number associated with the method, the older is its initial date of publication. Most of the commonly used tests for characterizing the mechanical performance of plastics fall into this group, including tensile testing, flexural testing, and the notched Izod impact test. Unlike the HDT test, these other tests had already been well established for metallic materials and were simply adapted for use in plastics.

It is true that methods are periodically reviewed and updated; however, the general framework for performing the HDT test has not changed significantly since its inception almost 80 years ago. ISO 75 is the international analog to D 648. It contains provisions for a greater variety of sample configurations and has instituted a third stress level that is significantly higher than the two that are used in the ASTM version. But the two methods have essentially the same purpose: to identify the temperature at which the modulus of a material declines to a specific value.

Dynamic mechanical analysis first emerged as a relatively user-friendly tool for material characterization in the 1960s, although the idea of using experiments that oscillated a material to learn about its properties goes back to 1909, coincidentally the year that Leo Baekeland invented phenolic. DMA is a very versatile technique and can be performed on liquids and melts as well as solids. By the 1980s, instruments capable of easily performing tests on solid materials of even very high stiffness were in use and it became feasible to develop the types of curves that we showed for PBT in my February column. The initial ASTM methods for DMA were being developed during this time frame and many variations exist today.

When I first started running DMA tests in the late 1980s, the industry people who seemed most interested were from the thermoset side of the business. Manufacturers of thermosets have long been frustrated by the HDT test because many of their materials, which have evident practical advantages over high-performance thermoplastics at elevated temperatures, often display a lower HDT. The DMA curves painted a more accurate picture. When I began showing DMA curves at conferences, everyone from the industrial disciplines wanted to know where the data came from. It is a question that I still get today, which underscores the lack of awareness in the industry regarding what is available to help us better understand our materials.

Of course, the academicians and polymer researchers knew all about DMA. But they were not using it to better communicate engineering performance. They were using it to delve deep into polymer structure and viscoelastic properties. The publications on DMA are full of complex ideas and daunting math that do not typically attract the interest of designers and engineers tasked with developing products, even though the underpinnings of viscoelastic theory govern everything that happens to our plastic products once they are in use. In most scientific disciplines, you have theoreticians who think about foundation problems, experimentalists who verify or overturn the theories, and engineers who figure out the details of turning these discoveries into products.

Unfortunately, in the world of polymers, these groups tend to be very insular and ignore each other. DMA was a casualty of this approach; it remained a research and development tool, and the engineering community that so desperately needed better tools for assessing polymer performance remained oblivious. The versatility of DMA was obscured by its complexity, and without a spokesperson who could articulate its attributes in practical terms it was ignored by the very people who could most benefit from it.

But it is time that we grew up. From an engineering standpoint, the most practical use of DMA is to provide a complete picture of how modulus changes with temperature. If we simply started there, it would be possible to replace HDT data tomorrow with curves of modulus as a function of temperature. From there, it is possible to illustrate the analogy between the effects of temperature and the effects of time under load. DMA provides a very rich and detailed picture of polymer performance, and it can be challenging to develop a complete understanding of all the things that we can and should know about our materials. But the fact that it may be hard does not mean that it should not be attempted. If the plastics industry is going to make a credible case for capabilities such as metal replacement, we cannot continue to provide designers and engineers with HDT values and assume that we have given them enough information to make intelligent decisions about material performance.

I sat in on a webinar a few months ago regarding replacing aluminum with glass-filled nylon in an automotive application. At room temperature the modulus of the two materials was represented to be comparable and the range of temperatures for the application was -40 C to 120 C (-40 F to 248 F). After the webinar, I contacted the presenter to point out that the properties of the glass-filled nylon decline by approximately 50% between room temperature and 120 C, while the properties of aluminum would be essentially unchanged. I wanted to know how that would be communicated to the engineer doing the conversion. When he asked me how I knew this, I told him I had DMA curves. His response: “Well, those are hard to find.” And that is exactly the problem.

As it turns out, they are not that hard to find. Many material suppliers, especially those who produce higher performing polymers, have been publishing them in their design manuals for years. They can also be found in some of the better material property databases. But there are problems. Because much of these data were developed by those comfortable with DMA theory, they are not always presented in a form that is user friendly to engineers and part designers. In our next article we will discuss some of these presentation problems and show how to get the most from the available information.

ABOUT THE AUTHOR: Mike Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe, LLC, is based in Sedona, Ariz. He has more than 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

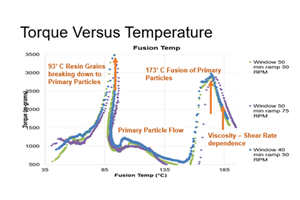

Try This Alternate Method for Heating Your Torque Rheometer

Rheometers are generally not on all the time. And most users have found that the first test run in the instrument after heating up is not very reliable and is usually discarded. Try this method instead.

Read MoreHandheld NIR Instrument Distinguishes PET from PETG

Mobile spectroscopy from trinamiX detects more than 30 different plastics—and now PET vs. PETG as an aid to recycling.

Read MoreK 2022: ‘All-in-One’ Bottle Tester Takes Three Measurements at Once

Delta Engineering’s new system performs simultaneous topload, height and both pressure-decay and high-voltage leak testing.

Read MoreDatacolor Launches Annual Subscription Payment Program for Color Management Software

The subscription plan is available for Datacolor Tools color QC application for plastics and other software products.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)