Service Helps Manufacturers Buy Energy When the Time is Right

Insulating manufacturers from market volatility can pay off big, as one firm can attest.

Processors have long identified material as their biggest expense and many have taken steps to do whatever possible to mitigate those costs, including using third parties to negotiate on their behalf with suppliers or replacing one resin with another. Even in the face of a labor shortage, people are expensive too, and more and more processors have turned to automation to do jobs operators used to do. But energy, which by some estimates accounts for up to 15% of overall expenses in a typical plastics-processing operation, has been largely overlooked, and a start-up company intends to rectify that oversight among manufacturers of all kinds.

“Imperium Predictive Analytics was a concept born out of the desire to optimize the way energy is purchased,” says Arthur Kaplan, a founding partner and Imperium’s chief sales officer. “We saw a complicated system built for the energy companies, and not the businesses who use their product. We are focusing on our industrial manufacturing and processing community as we see a large need for reduced energy spending without limiting output, which meaningfully impacts the bottom line.”

Data-Backed Procurement

The firm’s strategy is to use analysis of the energy markets to save money for its clients. Kaplan explains, “If you know the best time to buy, you insulate yourself from market volatility in the long term. We take 25 pieces of data spanning the last 30 years and couple that with algorithms we started to create three years ago to achieve predictive accuracy of 90%+ on average. Simply buying at the right time, when prices are lowest, is the most powerful way to reduce energy expense. Brokers call when you’re up for renewal; they simply do not know where the market is moving and do not have your bottom dollar in mind.”

“If you know the best time to buy energy, you insulate yourself from market volatility in the long term.”

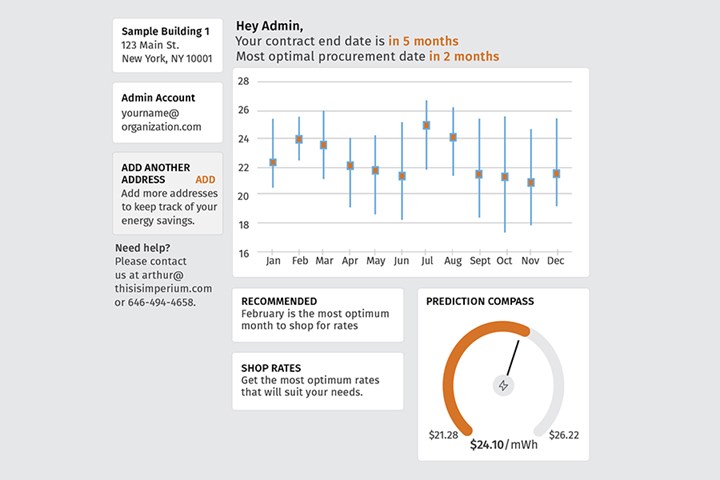

Imperium’s clients, on the other hand, have access to an easy-to-use dashboard where they can not only buy quickly but also see energy data on multiple locations at once, regardless of the energy supplier for that building. “We take care of fractured and inconsistent billing and procurement processes for you, making the process simple and transparent from start to finish,” says Kaplan.

In addition to our data strategy, Imperium offers manufacturers the ability to assess individual building needs to determine physical upgrades that would reduce energy use at the source. “We often discover that elements such as building seals, windows, and lighting are often neglected and can turn into a large drain on energy. We partner with long-standing companies nationwide to provide consultation on your buildings to determine what minimally invasive upgrades can optimize your energy use. These upgrades can often be financed via the savings the company is getting through Imperium, so there are no large up-front costs for these upgrades.”

One Manufacturer’s Experience

In a real-world example of its strategy at work, Imperium pointed to a medium-size plant in the Midwest that uses 9 million kWh annually at a cost of more than $600,000/yr, or $55,000 a month. This company, which asked to not be identified, wanted to save money on energy but had no interest in reducing capacity or slowing down production to get there. (Note: although this is a food-processing plant, its experience with Imperium’s service would seem equally relevant to plastics processors.)

Imperium clients get access to an easy-to-use dashboard that helps them buy quickly and see energy data on multiple locations at once. (Illustration: Imperium)

Kaplan notes that this company was not working with a supplier to lock in utility rates, making it vulnerable to the volatility of the energy market. “We determined the best time for them to purchase and locked in a lower rate within 30 days,” Kaplan adds. “This company saved 23% on their energy at their next billing cycle, which equated to $13,000/month, or more than $150,000/yr in annual savings. This was achieved without shutting down one single machine or interrupting their production at all. Early next year we will be replacing their facility lighting with energy-efficient LED alternatives and installing solar panels on the roof to reduce their usage by close to 15% overall, compounding their savings.”

The customer’s plant manager adds, “The ease in signing up and working with the Imperium team has been second to none. Transparency is important to us, and what you see is what you get with them, no shady sales techniques. Our operations team loves the dashboard management, and our finance team loves the savings we’re getting with Imperium’s artificial-intelligence procurement.”

Kaplan adds, “Other brokers typically stick you on the back burner until your contract comes up for renewal, but we monitor energy on your behalf 24/7 to realize further savings. If we see an uncharacteristic dip in pricing, we will present the opportunity to blend and extend your contract and capture that delta. Consulting on physical upgrades to further reduce usage and informing clients of legislation that could affect their energy costs are additional ways that Imperium differentiates itself. We don’t stop working on our goal to reduce what you use and what you spend on that usage.”

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)