Higher-Performing Biopolymers Seek New Market Opportunities

A new generation of biodegradable polymers is going beyond conventional applications like bags and disposable cutlery and packaging.

A new generation of biodegradable polymers is going beyond conventional applications like bags and disposable cutlery and packaging. Two German biopolymer suppliers are focused on delivering improved processability and better performance to meet more demanding uses. These new cellulose blends, polylactic acid (PLA) blends, and polyhydroxybutyrate (PHB) compounds are aimed at medical and diagnostic devices and barrier packaging in addition to more standard packaging and disposable uses. Both PLA and PHB are derived from bacterial fermentation of plant starches or sugars.

Emulates LDPE film

FKuR Kunststoffe GmbH, in collaboration with the Fraunhofer Umsicht Institute in Oberhausen, Germany, has developed a PLA/polyester blend that reportedly processes like LDPE film. Tests show that the new Bio-Flex 219F material can be processed on conventional blown film lines without modifications to screws, dies, and take-offs, says FKuR.

The company claims easy processing results from the high compatibility of the blend components. The formulation consists of more than 10% PLA (purchased from NatureWorks LLC, formerly Cargill Dow, Minnetonka, Minn.) plus a biodegradable copolyester and special additives. FKuR says a special combination of compatibilizers permits coupling between the PLA and the copolyester. The compound is homogeneous, which allows the film to be drawn down to 8 microns. Film up to 110 microns thick is 90% degraded after 12 weeks in composting conditions.

Bio-Flex 219F is targeted for shopping bags, mulch film, and laminates for trays. FKuR has also developed Bio-Flex grades with higher stiffness. Grade 466F (more than 20% PLA) and grade 467F (more than 30% PLA) are for shopping bags. Grade 482F, with more than 70% PLA, is for cast film.

Another offering in FKuR’s Nature Compounds line is a modified cellulose with processing characteristics and mechanical properties similar to polystyrene. Injection moldable Biograde 300A for foodservice applications like cutlery is white in color and produced with natural fillers and a special vegetable oil. It boasts high thermal stability and can be molded on standard machines with a general-purpose screw. The material is notable for its low shrinkage and virtual absence of warpage, according to the company. Up to 20% regrind can be processed without deterioration of properties.

Biograde 500A is slated for introduction later this year. It will contain special additives that permit the material to be thermoformed into hot cups.

Versatility in processing

FKuR also recently introduced Biograde 200C, an unfilled cellulose blend with high stiffness and transparency for cast film and injection molding. The material can also be blow molded into bottles and thermoformed into cups and trays, according to Patrick Zimmermann, FKuR’s sales and marketing manager. Injection molded Biograde 200C exhibits properties comparable to polystyrene—but with the addition of barrier performance comparable to PLA. It consists of 100% renewable resources, but does not contain starch.

FKuR opened in 1992 as a plastics recycler and launched its biopolymer business in 2000. The company has capacity of more than 6 million lb/yr and sells in all global regions. Zimmermann forecasts 25% growth in 2005 as the company enters new markets like mulch film. Products range in cost from 2.85 to 3.70 euros/kg.

Medical shows promise

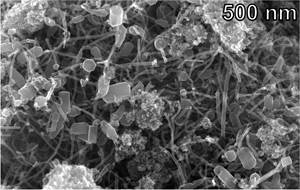

Biomer, another German biopolymer maker, is exploring new markets for its PHB and PLA polyesters. Biomer develops microorganisms that ferment sugar or starch syrup through a toll manufacturing arrangement. The polyester extract is then compounded with low- and high-molecular-weight plasticizers, nucleators, and processing aids to produce three standard injection molding formulations. Melt viscosity is very low, so high clamp force is not necessary to produce complex structures. The materials are said to process like liquid-crystal polymers and have MFR above 20 g/10 min. Biomer says 1.2-mm-thick samples of its materials degrade in a composting environment within six weeks.

Grade P226 reportedly has mechanical properties similar to PP, is easy to mold, and offers fast cycles. Grade P209 has properties similar to HDPE but elongation at break is significantly lower because of the material’s crystalline structure. Grade P240 is a higher impact version of P209.

Injection molded applications include medical "Immunostick" diagnostic tools, fireworks casings, and practice artillery shells for the military. PHB is also extruded into multi-filaments for woven surgical patches. Biomer president Urs Hanggi says the company is developing PHB grades with higher melt strength for blown film. Biomer also produces smaller amounts of PLA for transparent medical diagnostic strips, which are injection molded.

The company is experiencing strong growth, particularly in the U.S., says Hanggi. Capacity is several tons per month. PHB prices range from $5 to $10/lb. Hanggi believes PHB is destined for food packaging such as yogurt cups and beverage bottles. However, a big obstacle is obtaining food-contact approvals. Due to the many substances present in the residual biomass, food-approval testing becomes prohibitively expensive, according to Hanggi. Biomer has put its food-approval effort on hold until it can secure a commitment from a large food processor.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Biodegradable Polyesters: Packaging Goes Green

The U.S. is catching up with Europe and Asia in exploring the potential of biodegradable polyesters in flexible and rigid packaging. Because of their cost, these resins often find use in blends with other degradable materials.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More