Highlights of Fakuma 2015

A selection of the hottest news and molding trends at this “little brother” to the K Show.

The Fakuma 2015 International Trade Fair in Friedrichshafen, Germany, attracted 1780 exhibitors from 38 countries and more than 45,700 visitors from 120 countries. Although its scope is gradually enlarging, this is still overwhelmingly an injection molding event. What follows is a selection of some of the news and trends from the 24th Fakuma show in October. A good deal of news in primary and auxiliary equipment was covered in our October and November Keeping Up and Starting Up sections, and look for more news in those sections of this issue and next month.

NEWS IN MAJOR MACHINERY

Press makers introduced a number of new features and systems:

• Micromolding: We reported in October’s Keeping Up section on a new two-stage micro-injection unit from Arburg (U.S. office in Rocky Hill, Conn.) with 15- or 18-mm screw that accepts standard pellets. Boy Machines (U.S. office in Exton, Pa.) introduced what it says is the smallest single-stage reciprocating screw for micromolding (i.e., without preplasticator). The 8-mm diam. unit holds only 1.9 cc of melt in the flights, for very short residence time (82% less than for a 14-mm screw, the company says). It molded a PBT shot of only 0.06 cc, weighing 0.078 g.

• New sizes: As reported in October and November Keeping Up, Engel (U.S. office in York, Pa.) introduced a larger 80-m.t. size in its all-electric tiebarless e-motion TL series; and Wittmann Battenfeld (U.S. office in Torrington, Conn.) announced the completion of its SmartPower servohydraulic line with models of 180, 240 and 350 m.t. Wittmann also introduced medical versions of three press lines.

From Haitian of China, the Jupiter II Series of servohydraulic two-platen models is now available in “Jupiter II plus” versions with a redesigned clamp that offers 40% faster dry cycle (i.e., cut from 6.5 sec to 4.2 sec for a 450-metric-ton model) and eliminates lubricating cylinders around the tiebars. New linear guides replace tiebar guidance; and a digital, contact-free position-measurement system is said to provide rapid response and high-precision positioning.

Also from Haitian, the Zhafir Venus II all-electric machine has been upsized to 650 m.t. (as seen at NPE), and a 1000-m.t. model is due next year. The new Zhafir Zeres all-electric line with integrated servohydraulics for nozzle touch, ejection, and core pulls (also shown at NPE) has been extended beyond the original size range from 40 to 230 m.t. to 550 and 650 m.t., with larger models to come. (U.S. represententative is Absolute Haitian Corp., Worcester, Mass.).

In development is a new generation of Zhafir Mercury ME-X all-electric tiebarless models, which also will have integrated servohydraulics for secondary functions.

Fanuc of Japan (sold here by Milacron LLC, Batavia, Ohio) showed off a new size of Roboshot all-electric press, the alpha-S130iA (130 m.t.), which fits between 100- and 150-m.t. models. Fanuc also has new Roboshot SI-20A electric auxiliary injection units with 14-, 16-, and 18-mm screws, capable of shot sizes from 9 to 14 cc.

• New features: Sumitomo (SHI) Demag (U.S. office in Strongsville, Ohio) unveiled new enhancements for its IntElect all-electric presses. Among the new standard features, several injection units for the line are now available with a choice of five, rather than three, different screw sizes, allowing more versatility for processors to comply with residence-time limitations in sensitive applications.

During injection, the pressure profile can now be monitored with high precision. An adjustable tolerance band allows better process control and protects the mold from overfilling. There is also a new, standard display of the machine’s energy consumption.

A number of optional features have also been updated. The ejector-force profile across the entire forward and backward stroke can now be monitored with a high level of sensitivity. This is said to offer a new level of mold protection while also enabling high-speed ejector motions. Another optional add-on is the new integrated hydraulic unit with servo drive for faster nozzle travel and for actuating core pulls.

The new activeMoldWater module provides electronic cavity-temperature and flow-rate monitoring. And the activeFlowBalance module has been updated to make it even easier to use. This function balances filling in multi-cavity molds and single parts with hard-to-fill areas. The system allows the melt to decompress as it fills the cavities by halting the screw for a fraction of a second at the transfer point from injection to holding pressure. This allows the natural expansion of the compressed melt (up to around 5%) to top up the filling levels in the partially filled cavities.

KraussMaffei (U.S. office in Florence, Ky.) has upgraded the energy efficiency of its CX hydraulic two-platen machines by about 10%, as reported in October Keeping Up.

Arburg showed a servohydraulic Allrounder C Golden Edition with continuous oil-quality monitoring (particle counting) to indicate when an oil change is due. The company also improved the positioning accuracy and durability of the rotary table on its vertical 1200 T and 1500 T machines. In addition, Arburg has extended its large electric Alldrive machines of 250-500 m.t. by offering three performance variants: the current version aimed at special applications; a “standard” version with options; and a higher-performance packaging version.

• Lightweight composites: As reported in last month’s Starting Up, Sumitomo (SHI) Demag molded nutcrackers using three plies of unidirectional PP tape with continuous glass fibers. What was new was use of heated grippers to handle the pre-consolidated tapes instead of a preheat oven, before overmolding. Sumitomo also used an infrared camera and software from the South German Plastics Center (SKZ) to monitor a thermal “map” of demolded parts.

KraussMaffei overmolded organic composite sheets with long-glass/PP in the form of a 60% long-glass concentrate let down with neat PP. What was new, according to KM, was the ability to ensure precise metering of the long-fiber pellets in order to maintain the correct percentage of long fibers in the final mix. This involved two gravimetric feeders, one of them a C-Flex M flex-wall feeder from Motan Colortronic (U.S. office in Plainwell, Mich.), used to overcome the complex flow properties of long-fiber pellets. As a result, fluctuations in fiber content were said to be reduced significantly.

NEW FOAM PROCESS

Arburg demonstrated its new Profoam process for physical foaming with nitrogen or carbon dioxide. The gas is introduced into the feed hopper, not through a barrel port as with other methods. The two-chambered hopper has an upper chamber that is depressurized when loading pellets and pressurized when full. Then the pellets are discharged into the lower chamber, which is kept at 30-50 bar pressure (435-725 psi) to force the gas into solution in the hot melt. Besides the special hopper, the only other hardware modifications are two extra seals on the barrel and feed throat.

An Arburg source at the show said no Profoam systems had been sold yet, but Arburg uses the process internally to produce a switch housing for the safety doors on its machines. This is a thick part, and foaming yields reduced warpage.

NEW LOOKS IN ROBOTS

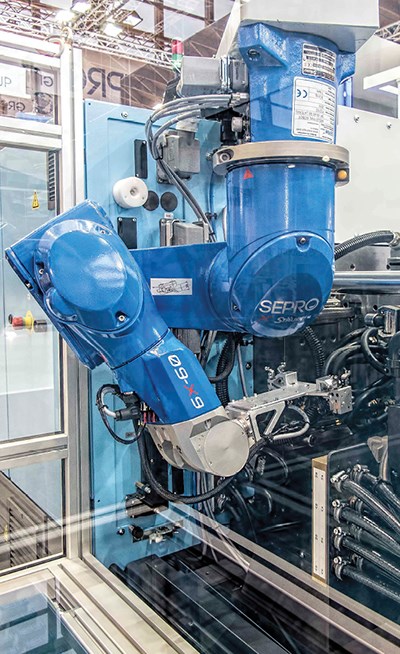

Automation was the name of the game at Fakuma, but with some new twists. Six-axis, articulated-arm robots were much in evidence, but what was particularly noticeable was that so many of them were mounted on top of the fixed platens of injection machines. Engel had a large easix model positioned over its multicomponent clearmelt cell (see opening photo). Most of them, however, were small models that operated within the envelope of the machine’s guards. One example was a Sepro 6X robot on a Sumitomo (SHI) Demag press (Sepro America is in Warrandale, Pa.). Small models from Kuka Robotics (U.S. office in Shelby Township, Mich.) hung from the platens of Netstal, KraussMaffei, and Boy presses.

The one shown by Boy was different from others, however, in that it was a new seven-axis model of a “collaborative” robot from Kuka that can operate around people without safety guarding. Torque sensors stop the motion of the robot on the lightest contact, and it resumes motion once the obstruction is removed. Another seven-axis Kuka collaborative robot loaded and unloaded a Freeformer 3D printer at the Arburg booth.

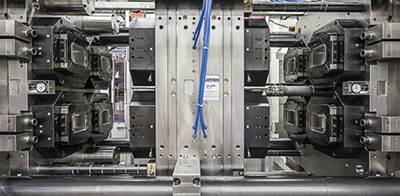

While this robot had a sleeker appearance than most articulated robots, a totally different look was on display at the Netstal and Fanuc exhibits. These futuristic, super-fast pick-and-place units were aptly termed “spider robots” by Machines Pagès of France, which supplied the IML system for Netstal’s groundbreaking demonstration of IML with a stack mold (see October Keeping Up). Also called “parallel” or “delta” robots, these devices have been used for several years as assembly robots, but this may have been their first appearance at a plastics show. Netstal (U.S. office in Florence, Ky.; netstal.com) used a small Kuka six-axis robot hanging off the machine platen to demold eight PP IML margarine tubs. The Spider robot picked them up one by one and placed them on a stacking fixture. A rationale for use of the spider robot was that it could pick out any random defective parts and dump them in a reject container without sacrificing the entire shot.

Spider-style robots also appeared at the Fanuc booth (U.S. office in Rochester Hills,

Mich.), where a pair of small M-1iA delta robots sorted micromolded parts by cavity. Fanuc’s optional iRVision allows the robot to recognize and locate different parts produced by a family mold in random positions.

NEW CURE FOR THE SHAKES

In recent years, makers of servo robots have attacked sources of vibration in order to achieve greater positioning accuracy for placing inserts or transferring pre-molded parts for overmolding. Robot vendors have approached the problem mechanically, by constructing robots of more rigid materials like carbon fiber, and also electronically, with control algorithms that counteract the oscillations caused by inertia when robots start, stop, or change directions. At Fakuma, Engel announced an effort to take electronic vibration control a step further. Up to now, its Viper Cartesian robots have used vibration-control algorithms that calculate the amount of vibration based on the programmed path of the robot, and then signal small motions of the servo drives to counteract the predicted vibrations.

Engel’s new active vibration control operates in real time, using acceleration sensors, and thereby can respond to variable or unpredictable external forces. An example would be the momentum imparted by the robot’s own kick stroke. Another would be the case of a part sticking momentarily in the mold and then releasing, causing additional vibrations. Engel says active vibration control helps the robot reach a stable working position more quickly, shortening cycle time, and to achieve greater positioning accuracy. All Engel viper robots will be equipped with active vibration control.

Engel also revised its Viper linear robots with a new drive package that automatically adapts the robot’s speed to the actual weight load. Thus, they move faster when bearing lighter loads and slower with heavier ones. Machine operators no longer need to set robot operating speeds. Within three molding cycles, the robot “learns” the optimal speeds for the current job—for example, slowing down during a long cooling cycle without adding to the overall removal time.

Wittmann Battenfeld also announced new robot control features. It showed a W833 pro all-servo model with new onboard weighing of parts as a quality check after demolding. The robot also uses this function to measure the weight of the EOAT (proportionately much larger than the part weight) and then adjusts its accelerations accordingly.

Also new from Wittmann is an A-C servo wrist for the W832 pro through W843 pro models, suited to presses from 400 metric tons and up. The new wrist is slimmer and has a completely closed execution; it costs no more than the previous version.

HOW MUCH CLAMP FORCE IS ENOUGH?

At Fakuma, Engel added a new “iQ” (“intelligent quality”) function for the clamp end of the machine. New iQ clamp control uses expert software to find the optimum clamp pressure for each individual mold. If clamp force is too low, parts can be prone to flashing or visible burrs that impart a feathery edge to parts. Too-high clamp force can impede venting and result in burning or “dieseling” of parts. It also adds unnecessary stress to molds, shortening tool life, and wastes energy.

Engel explains that because manual measurement of clamp force is subjective and imprecise and requires expertise to interpret the data, many molders simply use the maximum clamp force available. Engel addressed this situation with software that automatically measures the mold’s response to clamping. When the machine clamps up, it compresses the mold slightly. Some of that compression is reversed by the internal mold pressure when the mold is filled. That slight expansion is what Engel terms “mold breathing.”

Engel found a way to measure mold breathing without need for any sensors other than those normally on the machine. The software measures the final mold position during a dry cycle and during injection; the difference is mold breathing. Over three to 10 cycles, the software changes the clamp force in increments until it can extrapolate a characteristic curve for breathing vs. clamp force and determine the optimum clamp force as the inflection point just before the curve bends sharply upward.

This new software will be available for CC300 controllers on Engel machines having electric clamp units up to 220 m.t. Engel notes that it is a valuable adjunct to iQ weight control, which adjusts switchover point and holding pressure, because changes in either parameter can affect mold breathing. The iQ clamp control has an additional advantage in that the curve of mold breathing vs. time during the injection cycle is very similar to the curve of cavity pressure vs. time. As a result, data from iQ clamp control can be a proxy for cavity pressure without need for costly mold sensors.

Among other controls enhancements at Fakuma, Boy Machines introduced injection/compression molding as a new function for its small servohydraulic machines. Boy also introduced a new online energy calculator (accessed via the Boy app), which calculates the energy demand to mold a part of a particular material at a particular cycle time.

KraussMaffei premiered the use of its APC (Adaptive Process Control) function in LSR molding. APC determines the viscosity of the material during the cycle and adjusts the filling volume during the same shot to maintain uniform part weight. KM says APC is valuable for LSR because the latter is vulnerable to significant batch-to-batch variations in viscosity.

Related Content

New Tool Steel Qualified for Additive Manufactured Molds and Dies

Next Chapter Manufacturing says HTC-45 — an optimized H-13 — will offer superior thermal transfer and longer tool life.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreKraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

Read MoreRead Next

Lightweight Composites & Superfast Container Molding at Fakuma Show

Overmolded UD tapes replace organosheet with major weight savings. And 4 PP cups molded in 1.55 sec.

Read MoreINJECTION MOLDING: Sneak Peek at Fakuma News

News in LSR, micromolding, IML, medical technology, and more.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)