Hot Runners for Large & Small Parts Debut at NPE 2009

Although we previewed a number of new developments in hot-runners at NPE 2009 in our May and June issues, the big show in Chicago served up still more new offerings for PET preforms, medical parts, caps and closures, and more.

Share

Although we previewed a number of new developments in hot-runners at NPE 2009 in our May and June issues, the big show in Chicago served up still more new offerings for PET preforms, medical parts, caps and closures, and more. So here’s the rest of what we found, including more details on some products for which few specifics were available before the show. This article supplements previously reported news from Thermoplay/Alba Enterprises, D-M-E, Ewikon, Heitec/Technoject, Husky, Incoe, Mastip, Manner, Melt Design, Mold HotRunner Solutions, Osco, and Yudo (see Learn More box below or online).

PET PROGRESS

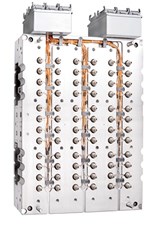

Mold-Masters now offers complete hot halves for PET preforms with two to six drops. These Master PET hot halves have brazed-in nozzle and manifold heaters for improved uptime and precise control. Larger flow diameters and shorter flow paths reduce shear, leading to 10% lower fill pressure and allowing fast color changes. Users can easily replace tip/seal combinations without removing the nozzle heater, and valve pins can be accessed individually through cover plates on the backing plate.

Yudo is making a foray into PET preforms, unveiling a complete tooling system and what’s said to be the first stack mold for this application. Yudo exhibited a 48-cavity, single-face tool for 0.5-liter performs and a prototype 2 x 32 stack mold for 0.5L. Yudo plans to demonstrate the capability of the stack tool by year’s end.

HIGH SPEED, HIGH CAVITATION

Incoe introduced its new Quick-Flo (QF) hot-runner systems designed for commodity resins in high cavitation. The QF series targets caps and closures, medical disposables, and pharmaceutical and other packaging. Nozzles are offered in three sizes with flow-channel diameters of 3, 5, and 8 mm, providing shot sizes from 3 to 375 g. They have twin heaters for fail-safe operation, and the heaters are profiled into the nozzle body. The system is sold as a complete hot half.

Mold-Masters launched its new Sprint system for beverage closures and other parts with molding cycles between 3 and 6 sec. It has a patented bimetallic tip design for superior gate-vestige control, and large flow channels for fast fill and decompression without stringing. The system reportedly delivers greater than 90% balance at 90% fill and accomplishes color changes in fewer than 50 shots.

TARGETING LARGE PARTS

Mold-Masters also launched its new Fusion G2 line of drop-in systems for medium to large parts. It comes completely prewired and assembled. This re-engineered version of the Fusion series launched two years ago now has a single-point connection for easy installation, faster start-ups, and convenient maintenance. It’s also 30% lower in price. Key features include slim-profile, screw-in nozzles that are threaded directly to the manifold; multiple heater zones per nozzle for optimized thermal profile; and leak-proof design. Three standard configurations handle shots of 15 to 3500 g per gate. Minimum size for the previous design was 500 g.

Yudo unveiled its Screw-Modu drop-in system for large parts, which comes fully assembled. Replacing the Eco-Modu line, it has nozzles that screw directly into the manifold to minimize leakage, plus guided nozzle tips for easy assembly. The system uses Yudo’s SCN 35 or SCN 45 nozzles to process a wide range of amorphous or crystalline materials.

FURTHER DEVELOPMENTS

Mold-Masters introduced its Femto-Lite line of valve-gate nozzles for small medical, personal-care, and closure applications. They are said to combine the company’s smallest valve gate with an unusually large bore (6 mm) to minimize pressure drop. The compound nozzle design has a single heater, a longer flange and valve pin for added strength, and removable standard seals. It fits in pitch sizes down to 22 mm, and handles shots up to 5 g.

Mold-Masters also brought out the TempMaster XL-6 temperature controller, a simplified system for up to six zones. It has adaptive auto-tuning and auto-calibration.

Osco rolled out its newest Single-Cavity Valve Gate (SCV-100) for direct feeding of small to medium-size parts. The 100 series SCV nozzle is offered in a new two-stage air-piston design or a single-stage oil piston. Each nozzle has two temperature zones and 0.187-in. flow channels. The unit is smaller than the SCV-200.

D-M-E’s Stellar line comes in a new high-performance version in addition to the standard general-purpose line. Both are made from powdered metal that is formed into rod stock then machined. The high-performance line features a brass-embedded heater for improved heat transfer. D-M-E also introduced its Stellar 5000 single-drop hot sprue bushing for prototype and short production runs.

Incoe developed a new feature for longer nozzles in its Direct-Flo Gold series that eliminates the time and expense of adding a separate groove over the entire length of the nozzle bore in order to accommodate heater cables. These types of systems are typically used to produce large components with deep nozzle bores in the injection half, says Incoe.

New, economical manifolds for general uses from caps to bumper fascias come from PSG Plastic Service Group. Its Thermoject Econ line has simplified designs that cost 10% to 20% less than its premium line, and the scaled-back controller costs about 30% less. Overall cost savings are about 25%. The system is available as separate components, unitized construction, or complete hot half. Five standard manifold heights range from 33 to 70 mm and melt channels span 8 to 24 mm for shot sizes from 0.5 to 6000 g.

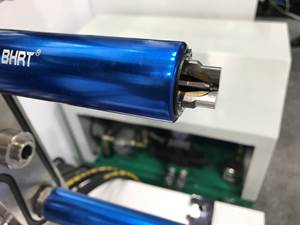

Manner’s new Sidegate line of valve-gate nozzles for side injection is now commercially available. They are suited to long, tubular parts for medical applications. Manner also expanded its 8-mm-diam. Slimline close-pitch nozzle for high-cavity molds into smaller two- and four-drop applications for small parts with shot weights of 0.01 to 10 g. In addition, Manner is starting its first U.S. production in Georgia, to provide components, complete bolt-on systems, cleaning, and refurbishing.

Related Content

PCR-Optimized Hot Runner System

Oerlikon HRSflow showcased the special PCR-ready hot runners in two applications—a fruit crate and household compost bin—with the crate molded at K 2022 by Haitian.

Read MoreMolders’ Block: Dealing With Foreign Materials in a Hot-Runner System

Understanding plastic flow can help you understand how foreign materials move—or don’t move—through your hot-runner system.

Read MoreNew Hot Runner Cooling Design Lowers Energy Consumption, Maintenance

Oerlikon says the HRScool Evo’s design eliminates separate, active water cooling for the hot runner pin’s hydraulic cylinder, reducing energy consumption by up to 10%.

Read MoreHot Runner Controls Add VPN Remote Access

Spark Industries says the new application provides a secure and easy way to connect to its hot runner controls from a remote PC—that is a device not on the same network as the HMIs.

Read MoreRead Next

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

Read MoreNPE News in Injection Molding

If a better machine can help your company beat challenging economic conditions, you’ll probably find it at NPE. And finding it will be easier, thanks to our editors’ efforts to sift out of some 2000 exhibits the most significant news in injection and blow molding, extrusion, compounding, and thermoforming.

Read More