How Currier Puts the ‘Custom’ In Custom Blow Molding

The three key ingredients are responsiveness, full-service product development, and control over both the bottle and the cap.

Currier Plastics in upstate Auburn, N.Y., is a relatively small custom molder, but it competes in consumer and healthcare packaging markets served by firms many times its size. Blowing bottles for personal care, beauty and cosmetics, household chemicals, and healthcare is not for the faint of heart. And one of Currier’s major market thrusts is into mini bottles for hotel amenities, travel sizes, and the like, where industry volumes are in the billions of bottles per year and pricing is rock-bottom. So how does a $30-million business thrive in such a competitive field?

Currier’s answer is by focusing on its strengths as a custom molder—with the emphasis on custom:

• Currier is all too happy to provide individualized solutions for customers, even to the extent of exploring brand-new technologies to solve unique problems.

• Currier also offers customers full-service product-development and engineering services. It uses laser scanning, finite-element analysis, 3D printing, computer simulation, and even motion analysis to advise customers on material selection and product design. Product development manager Joel Sieber calls this method “predictive design in a virtual environment.”

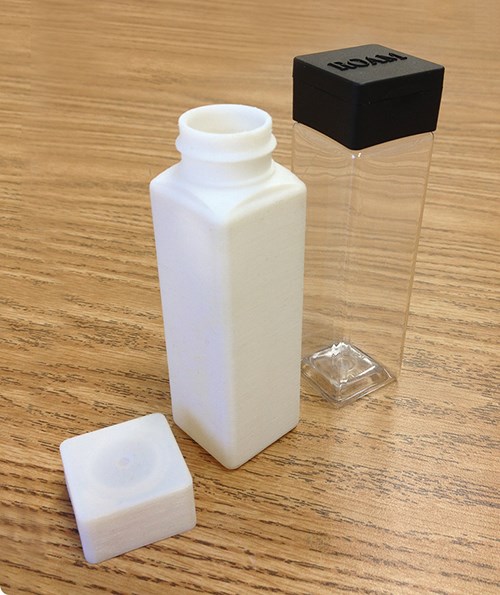

• Third, Currier gains substantial advantage by molding both the container and the closure for about 70% of its customers. “Our corporate mission is the whole package, meaning the bottle and the cap,” says Gary Kieffer, v.p. of new product development.

“Making both bottle and cap puts a stop to the finger-pointing when something goes wrong.” He adds that some packages require the cap to be oriented relative to the bottle. “So thread timing is key, and that’s difficult to achieve if you don’t control both elements.” In cases where Currier doesn’t get that control, it performs its own SQC analysis of a sample of caps and then adjusts the bottle neck design for the expected variability in cap threads and in how tight the customer might torque the cap onto the bottle.

Company president John Currier (son of the founder) adds another consideration: “When you control both the bottle and cap, you can often lightweight more than you could if they were produced separately. The reason is that it’s awfully difficult to ask the other guy to change his mold to help you save some material.”

Currier even molds some custom caps without the containers. “The big cap guys typically don’t do custom, and if they do, their response time is more than twice as long as ours,” says Sriraj Patel, injection molding product engineering manager and toolroom manager. “For a 72-cavity cap job, we can go from concept to production—including post-mold automation—in just 15 to 16 weeks.”

Add to these capabilities a tight focus on “lean” manufacturing efficiency and you get a pretty good picture of how Currier competes with the big boys at home and low-cost molders abroad. Clearly, the formula has worked: Its business has expanded 60% since the end of the last recession and an expected 26% this year alone. Employment has grown 18% in the last two years to 130 people today.

FROM ONE PROCESS TO THREE

Currier Plastics is a privately owned firm that began as a custom injection molder in 1982. In 1996, it expanded into extrusion blow molding (EBM). In 2010, Currier added another process, injection stretch-blow molding (ISBM) of PET.

Currier now operates 28 injection machines—up from 23 a year ago—in a range of 24 to 500 tons. It has 14 EBM machines, two of them added in the past year, with another on order. Its ISBM capacity has risen from five to eight machines since 2012. To accommodate this growth, Currier built a 40,000-ft2 addition last year dedicated just to blow molding, turning over all the original 65,000-ft2 space to injection molding.

From a business that was once 100% injection molding, Currier now derives 60% of its revenues from blow molding, divided 75/25 between EBM and ISBM. Most of Currier’s injection molding is now of closures for bottles and jars, as well as some electrical and healthcare parts (see blog). Although most bottle caps are PP, Currier created an HDPE cap for one HDPE bottle to meet the customer’s desire for enhanced recyclability.

Its blow molding business is quite varied. On the EBM side, it ranges from commodities like HDPE detergent jugs to more specialized products like coextruded bottles for a body lotion that have HDPE on the inside and soft-touch TPE on the outside. “We’re also one of the few custom blow molders that still runs PVC,” notes Max Leone, v.p. of business development. The main vinyl job in the plant currently is a bottle for a hair-coloring formula that is an oxygen scavenger, which tends to pull in the bottle sidewalls. Rigid PVC provides the needed combination of rigidity, squeezability, and chemical resistance.

Currier’s largest blow molded product used to be EBM HDPE dispensing canisters for wet wipes, which ran 20-30 million units annually. But Currier is currently expanding its market thrust into mini bottles (1.5 to 3 oz) beyond hotel amenities into travel-size containers and restaurant portions, which can run to 100-125 million a year for a single job. For example, there’s a 1.5-oz PET squeeze bottle for a restaurant portion of maple syrup that is being converted from glass. Currier molded hundreds of millions of mini bottles last year, both ISBM PET and EBM HDPE. “It’s an area of growth for us,” says Leone. “There are huge volumes, but it’s incredibly competitive. Hotel amenities are ‘free’ give-aways, so they have to be cost-effective. It requires very tight process control and product uniformity.” One unique version Currier produces is amenity bottles with Braille lettering on the side.

Currier’s ISBM products range from ultra-thin spherical and flat PET bottles with a 0.010-in. wall to ultra-thick perfume and cosmetic bottles in Eastman’s Tritan copolyester with walls of up to 0.250 in. to give the heavy feel of glass. There’s even an ISBM amenity bottle molded of 100% post-consumer recycled PET—fairly uncommon, says Steve Valentino, blow molding plant manager.

One highly engineered specialty is an ISBM pressure vessel molded of Eastman Chemical's Tritan. It’s all curves with no straight walls. Another special bottle is a 4.75-oz ISBM PET bottle for a new extended-release carbohydrate supplement drink. Its unusually complex shape is somewhat flattened, with rounded ends and large panels that are not actually flat but lightly “dished” or concave. It also has three highly elevated ribs on both narrow ends. Molding must be very precise, because the customer will apply a shrink label that conforms tightly to the bottle’s curves and ribs.

IN-HOUSE ENGINEERING

Currier has ample experience in helping customers develop products from even the vaguest of concepts. “When we started work on the wet-wipes dispenser, the customer had no specific design in mind,” recalls Kieffer. “The idea was something for the kitchen environment that would give an impression of high quality—that’s all. We drew up 18 different concepts, then winnowed down the list on the basis of manufacturability. We used computer graphics to simulate different product textures, colors, and lighting conditions in a home kitchen. We even asked the women in our company what they thought of the ideas.”

The home carbonation pressure vessel illustrates the kinds of technologies Currier can bring to bear on product engineering. The product was originally made of PETG and was suffering failures in the field. Currier used SolidWorks Premium Simulation to perform finite-element analysis (FEA) of structural properties, which indicated that the molded lettering on the sides of the vessel was a point of weakness that had to be eliminated.

Next, Currier recommended a different material—Tritan copolyester—to ensure the product could withstand repeated dishwasher cycles (a particular strong point for this unique resin), and performed further FEA work to determine the minimum wall thickness allowable. “Doing in-house FEA is unusual for a company our size, which would typically farm it out,” observes Leone.

This was followed by rapid prototyping on an Objet 30 inkjet-style 3D printer, which Currier purchased in 2012. “We use the 3D printer on most jobs today, especially for simulating the cap/bottle interface,” says Sieber. “We have simulated multiple thread-start positions to ensure correct orientation.”

For the Tritan pressure vessel, Currier used the 3D printer to produce parts of a prototype fixture to trim off one end of the part to expose a second set of threads.

Perhaps the most unusual aspect of that development process was an animated motion study to simulate the automated process for trimming the part in the fixture. “We had to make sure the trim process was reliably consistent and operator-safe,” says Steve Faes, CAD designer.

Faes made imaginative use of his computer tools on a project to optimize an HDPE detergent jug. Since this is a commodity product, Currier wanted to minimize wall thickness without compromising necessary strength and stiffness. Faes used a laser scanner to measure the dimensions of a molded jug when empty and when filled with water. Feeding this data into the SolidWorks system produced a tri-color map of the product, where gray represents the “perfect” CAD geometry, yellow shows any deviations in the empty blown bottle, and magenta shows further deviations in the filled container .

Faes is starting to build a database of the relationship of strength to stretch ratio in ISBM PET—an area where studies are lacking in the industry, he says. He’s also very interested in work on simulating the ISBM process conducted at Queen’s University in Belfast, Northern Ireland.

ORGANIZED FOR EFFICIENCY

Lean manufacturing is an expression one hears mentioned repeatedly at Currier. It influenced the company’s choice of molding machines. For example, all of its ISBM units are integrated one-stage injection and stretch-blowing systems from Aoki Laboratory America, Elk Grove Village, Ill. Control over the entire process in one machine was a key consideration, according to Leone. Adds Valentino, another reason is that “the product engineering is really in the preform, and Aoki has extensive experience in that area and provides a lot of help. Our entire team has visited them in Japan more than once.”

Currier streamlined its ISBM installations by moving the dryers off the floor onto the machine hoppers and designing the water manifolds so staff can quickly blow out the molds during changeovers. For the new building, an overhead crane was added so that one person can perform a mold change instead of two. (Overhead cranes were also added to the injection molding department.)

All Currier’s EBM machines have automated trimming. “We sold off our last mold-and-drop press. We’re big fans of in-machine trimming and prefer it to add-on automation if we can avoid it,” says Valentino. “With separate manual trim, one operator can handle four cavities in 16 sec. With in-machine trim, the same operator can run eight cavities in 15 sec.” In addition, every standup bottle is 100% leak tested on the exit conveyor at the machine. We’ve had zero leaks at production rates of 70-80 million bottles a year,” Valentino notes.

All Currier’s recent purchases of injection and blow molding machines have been all-electric presses, and that will be the trend in the future. On order is one of the latest all-electric EBM units from Kautex Machines, Inc., North Branch, N.J. It’s a KBB60 double-sided press with 12 heads, one of a new series introduced at the K2013 show in Dusseldorf . It will be running in Kautex’s booth at NPE 2014 in Orlando, Fla., before moving to Currier’s plant.

Since moving into the new building, the blow molding department has been reorganized into four cells—one for ISBM, one for large EBM presses, and two for smaller EBM units (separated by manufacturer—Heins or Automa.) “The goal is improved efficiency,” explains Valentino. “Cells bring more focused attention to a limited number of machines with common characteristics.” The injection molding department followed suit with a reorganization into three cells by machine size and product range.

“Automotive and medical manufacturing uses this approach, but not many custom molders,” says Steve Feaster, injection molding plant manager. Each cell is headed by a cell engineer, who is responsible for the machines, processes, automation, and efficiency. “It took us a while to define the role of the cell engineer,” recalls Feaster. “We decided that the cell engineers would have no direct reports, freeing them from that management burden. For plant managers and plant engineers, our job is to support the cell engineers. We’re measuring their performance every day, and we have a roundtable meeting once a week at lunch to talk over how things are going.”

A bulletin board on the molding floor graphs the performance of all the cells—distinguished by different colored trend lines—according to four critical factors: efficiency, floor scrap, production value relative to the schedule, and utilization relative to schedule. The data are published daily and graphed monthly. “It breeds healthy competition,” says Patel.

Another new feature of Currier’s reorganized plant layout is the location of multiple QA stations on the plant floor—one for each injection molding cell and three for the blow molding department. These stations cost $25,000 each to outfit with equipment for measuring—in one blow molding example—topload strength, bottle height and weight, min/max wall thickness and wall variation. One station also has a vacuum chamber. All measurement data goes automatically into the company’s central SPC database.

According to Valentino, the company’s goal is to achieve better efficiency through innovation. “We want technology to be the driver,” he says. On the blow molding side, Currier is evaluating multi-parting-line (MPL) technology patented last year by Fidelity Tool & Mold Ltd., Batavia, Ill. Similar to stack molds for injection molding, the tool has two independent parting lines, though the centerlines remain stationary. Special twin-row heads are offered for this process by W. Muller GmbH (U.S. office in Agawam, Mass.). Like stack molds, this approach can double machine capacity if the extruder is up to it.

Currier has also launched in-house initiatives to boost productivity. “On some machines, our engineers can squeeze 75% to 100% more cavities into an EBM mold,” boasts Valentino. “They can take a 6-up, double-sided machine and remodel it to run as many as 20 cavities. The machine builder didn’t believe we could do it.” The reason why is obvious: On a double-sided press, the extra cavities required enlarging the molds until they just barely miss touching each other when the two shuttles come together.

One project under way is to get customer qualification to use liquid colors for molded containers and lids. Valentino cites three advantages: Liquid colors give more homogeneous dispersion at low pigment levels for translucent products. PET pellet masterbatches require predrying. And pellet concentrates “leave color residue all through the handling system.”

Related Content

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MoreRead Next

On-Site: Custom Molder Pursues the Dream of Proprietary Products

“Every custom molder thinks he needs a proprietary product,” says John Currier, president and co-owner of the injection molding firm his father founded, Currier Plastics in upstate Auburn, N.Y.

Read MoreThe Customer Buys the Machine, You Mold the Parts

Currier Plastics houses and operates customer-owned injection and blow molding presses, cutting costs for both parties.

Read MoreThe Customer Buys the Machine, You Mold the Parts

Currier Plastics houses and operates customer-owned injection and blow molding presses, cutting costs for both parties.

Read More