When planning to invest in granulation equipment, selecting the right one for your application can take what started as a simple task and make it seem overwhelming once you start asking questions. When you hear buzzwords like low speed and high speed, you can start to wonder what you really need. They’re all the same, right? In a big-picture view, they all chop things into smaller pieces.

But what are you really buying? Think of a granulator as a tool, like a drill. In buying a drill, your goal is to pick one that lets you make good holes of the size you need in a particular sort of material. With a granulator, the ultimate objective is to convert your material from its present state into high-quality granulate that will allow you to reuse this material to the utmost.

So, where things start to get a bit more involved is that granulators do not come in a one-size-fits-all type of solution. To better understand this, let’s define what high-quality granulated material really means.

WHAT IS QUALITY GRANULATE?

Quality in granulate comes down to three main concerns:

• Cleanliness: It must be free of dust and fines, which represent lost material if separated from granules during air conveying; or, if not filtered out, can negatively affect processing when reintroduced to an extruder or molding machine. The material type enters into this consideration, as brittle materials may be more likely to shatter during granulation and produce fines and dust.

• Uniformity: Consistent granulate size leads to consistent bulk density and more consistent feeding and blending with virgin pellets—and more consistent melting in the machine barrel.

• Size: Choice of appropriate granulator screen size can help balance desired throughput with a final granulate size that is compatible with the particle size of your virgin infeed material.

Regardless of the industry you serve as a plastics processor, there will always be material that can be reclaimed. Whether it’s runners from the injection molding process, edge trim from a sheet or film extrusion line, or flash from blow molding , the materials in this form have value. This does not account for non-conforming parts or startup materials.

When you consider the rising cost of raw materials, increased demands for price reductions, and the end-user market desire to include recycled materials, the use of granulated material should be considered as a marketing opportunity as well as a cost control.

If this material is not handled correctly or simply discarded, there is a significant and direct impact to the bottom line. Taking the time to assign a dollar value to that material can result in a very quick return on investment (ROI). This material is also already on hand—the value is increased if it contains color, as the color concentrates can be even more costly than the resin itself. What’s more, if the color doesn’t match, the non-conformance can negatively impact your bottom line again. In addition to cost savings, reclaiming your scrap is the responsible thing to do.

Now that we have defined what we are trying to do, what do you need to know to select the right tool for the job?

With the advances in cutting technology and machine design, reductions in energy consumption, and increased automation available for size-reduction systems, there are many cost-effective solutions available to provide quality regrind for the manufacturing process without adversely affecting production rates, part quality or the plant environment.

Years ago, it was very common for processors to specify a certain size of granulator motor or cutting-chamber opening. Today, suppliers of size-reduction equipment like to ask specific questions to get processors the best solution.

QUESTIONS TO ASK YOURSELF FIRST

Here are the key questions that are important to reflect on to help select the best granulator for the application:

• What is your application? Most commonly we deal with blow molding, injection molding, extrusion, thermoforming and recycling, with distinctions being drawn between post-industrial and post-consumer varieties.

• What kind of material will you be looking to process? Material types can affect the recommendation. Both the generic resin type and the presence of fillers or reinforcements must be considered.

• How will you introduce the material into the granulator? Common methods are by manually feeding, feeding with a conveyor, pull rolls or robots, and blowing the material via an air-conveyance system.

• What will you be feeding? This will be a physical description of what is to be fed—i.e., bottles, sheet, film, pipe, or sprues/runners.

• What are the dimensions of what you wish to feed? Knowing the largest to smallest size range as well as wall thickness will help to guide the best granulator choice.

• How much throughput will you need? This is important to know and is usually expressed as lb/hr or kg/hr.

• What size granules do you want? This is the final output size, usually ⅛ in. (4 mm) to 1 in. (25 mm), with 5/16 in. (8 mm) to ⅜ in. (10 mm) being quite common.

Many of these questions may seem like common sense … and they usually are. While it’s difficult to find one question that is most important, one that seems to be very elusive is “How much throughput?” Really knowing this value can aid in the machine selection and ROI.

Buying a granulator that is too small or too large can have a big impact on the success of your project. Having a firm grasp of how much material needs to be processed is very important.

The connection between how much you need to process, and the granulator chosen can be directly tied to instantaneous throughput rate as compared with intermittent rate. It’s easy to undersize a granulator by considering only the intermittent rate.

To explain intermittent rate, let’s assume the information provided is for 600 lb/hr and your parts are 10 lb each. With this in mind, only one part per minute can be fed into the granulator. However, if 600 lb of material is collected until the end of the hour and the desire is to process them in 15 min, the instantaneous rate is 2400 lb/hr and the granulator choice is radically changed. But use caution, as a oversized granulator is also something you will want to avoid. If a large granulator sits idle and the rotor spins without parts, the energy efficiency ratio is greatly decreased.

In this example, if a 600-lb/hr machine is chosen and it is fed at the equivalent rate of 2400 lb/hr, the undersized granulator will end up being overfed and ultimately result in unscheduled maintenance. Granulators operate best with a steady diet at the rate for which it is designed.

There have been advances in cutting-chamber designs that allow granulators to perform at optimal levels, extending knife life, reducing dust and fines generated, and cutting energy consumption.

Accepting the fact that granulators do not come as one-size-fits-all, it is important to appreciate that the cutting-chamber type or design will have a significant impact on the quality of the granulated material.

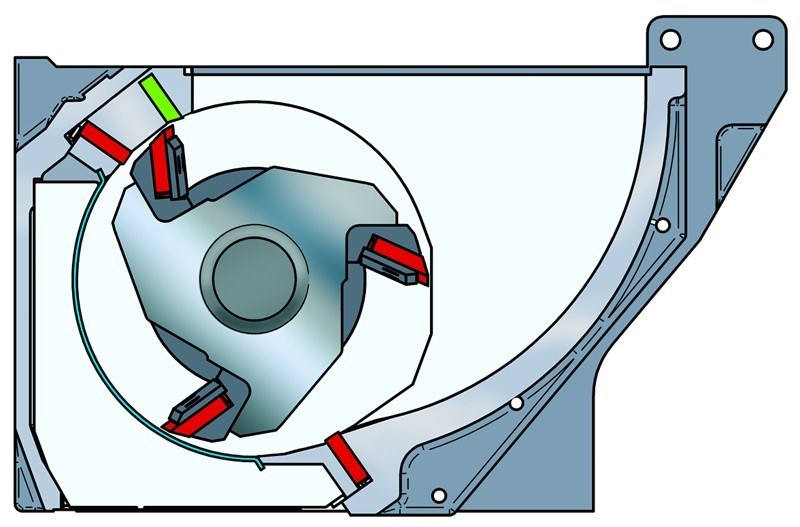

Using a blow molding application as an example, modern granulator designs will incorporate such technologies as the “super-tangential cutting chamber,” where there is a belly in the cutting chamber and the parts are more quickly consumed, thus minimizing the amount of time that the material spends in the cutting chamber. This more efficient cutting procedure can help extend knife life as the material is more quickly processed; reduce noise generation and energy consumption; and, most importantly, produce the high-quality granulate you seek. The right cutting-chamber design will be more efficient and can often allow a physically smaller machine to do the work that historically required a larger machine.

DON’T IGNORE MAINTENANCE

Unscheduled maintenance is costly, but also poor cleaning and not adhering to scheduled maintenance can be very expensive, subtracting from your bottom line.

Maintenance and cleaning of granulators and their critical components is usually the most neglected area of service in many facilities. Machines that are difficult to clean are usually directly related to poor design that prevents easy access to the cutting chamber. Modern granulator design allows for quick and easy access to the cutting chamber, reducing planned or unplanned downtime. Statistics tell us that cleaning and maintenance can account for up to 80% of the cost of running a granulator. Newer designs go a long way to reducing the overall impact.

Modern designs also extend to the cutting action inside the granulator. It is good to look for machines that employ a “scissors cut” to reduce the energy required and also produce the most uniform granulated material while reducing wear and tear on the granulator. The scissors cut helps reduce the overall impact on the cutting system, leading to lower power consumption, reduced noise, and more efficient operation.

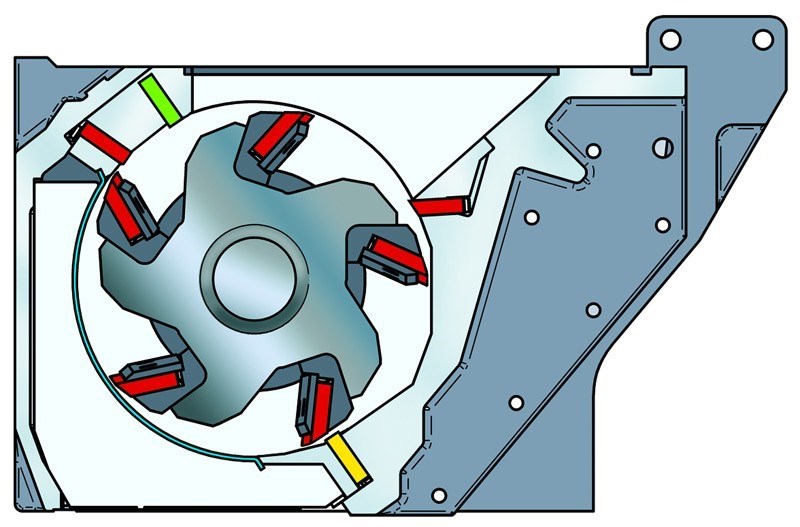

Another key feature in modern granulator design is adjustable rotating knives. These knives are connected to the rotor, which turns in the cutting chamber to produce the cut. The principle behind the adjustable rotor knives is to keep the knife tip as close as possible to the granulator screen. This eliminates an area where material can accumulate and reduces frictional heat, preventing screen clogging.

Many granulators have knives that can be sharpened and have about ⅜ in. (10 mm) of usable material when you sharpen the knives. The rotating and fixed knives get progressively shorter until they reach that minimum length.

In older granulator designs, these knives are fixed to the rotor without the ability to adjust them and only the bed knife can be moved forward to compensate for the material removed in the sharpening process. The sharpening process is a variable—it is quite difficult to get the knives all the same. The result is that you can end up with knives of varying lengths. If the length varies by more than 0.002 in., you can only set the bed knife to the tallest knife, and therefore only that one knife does most of the cutting. When this happens, it is difficult to get the knives all set to the same gap. This will also lead to increased heat and motor loads, adding hidden costs to your process.

While there are a lot of variables to consider, if you start with the ones above you will be well on your way to finding the granulator that is best for your application and will allow you to get the most benefit from the material you have already purchased.

ABOUT THE AUTHOR Jim Hoffman is v.p. of sales/marketing and service for Rapid Granulator Inc. in Leetsdale, Pa. He is responsible for sales in North America and has been with Rapid for more than 28 years. Rapid Granulator, Inc. is a wholly owned subsidiary of Rapid Granulator, AB of Sweden. Contact: jimh@rapidgranulator.com; rapidgranulator.com

Related Content

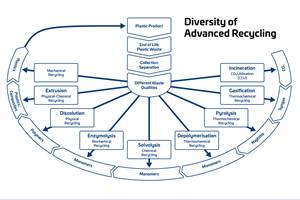

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More