How to Choose & Use Metal Separators

Tips and Techniques

Use of magnets for removing ferrous contaminants in an industrial environment began in the 1940s to help farmers trap and remove metal contaminants from their grain chutes.

Use of magnets for removing ferrous contaminants in an industrial environment began in the 1940s to help farmers trap and remove metal contaminants from their grain chutes. Today, in plastics and other industries, ferrous metal contamination can damage process equipment and create impure product that must be scrapped or sold at less than full value. This metallic contamination may come from a variety of sources. Incoming products may contain contaminants from the transportation vessel used to deliver the product, such as a tanker truck or railcar. Contamination may originate within the plant due to material processing, grinding, crushing, or general abrasion. And plant personnel can accidentally drop metallic objects into a container or stream of raw material.

Problems associated with ferrous metal contamination can be reduced or eliminated by using magnetic separation equipment. Magnetic separators are available in a wide variety of designs to remove ferrous material such as nails, rust, scale, bolts, welding rod, and other contaminants from dry or liquid products. This article will also briefly discussion detection and separation equipment for nonferrous metals.

Selecting the proper magnetic separator requires an understanding of magnetic properties, the process application, and environmental elements in each specific installation. Processors are advised to consult with a magnetic separator supplier.

PERMANENT MAGNET MATERIALS

The magnet material specified in a separator product generally refers to the magnetic pressings or castings used to develop the magnetic field within the separator. This material may be cut and arranged in a linear fashion using other materials to create a magnetic circuit. Depending on the desired outcome, circuits may be designed to cast a shallow-wide magnetic field, a deep-narrow field, or anything in between. This is why it is often difficult to compare competing products made of similar materials. Once the circuit is assembled, it is usually encased within stainless steel to protect the magnet material from mechanical damage, wear associated with product flow, or from contaminating the feed material.

Since their inception in the 1940s, there has been substantial change in the materials used to manufacture permanent magnetic separators. The following are the most common magnetic materials used over the past 60+ years:

•Alnico: One of the earliest magnet materials used for ferrous separation, Alnico magnets are castings of aluminum, nickel, cobalt, and iron. They are commonly recognized by their horseshoe shape. Although seldom used today, as there are more economical magnet sources, Alnico may still be used in applications involving temperatures above 400 F (204 C). This material is comparable in strength to ceramics and is used to remove relatively large pieces of ferrous metals, such as nuts or bolts.

•Ceramic: From the 1960s until the early 1980s, ferrite ceramic pressings were the standard in permanent magnetic separators. Ceramic pressings are easy to work with because they can be cut in all directions, assembled into a circuit, and then charged as a complete unit. Ceramic-magnet circuits work best when the goal is to remove relatively large pieces of ferrous metal contamination.

•Rare earth: The term “rare earth” is a misnomer. This magnetic material derives its name not because it is rare, nor because it is earth. It is so named because part of its makeup is one of the 14 Lanthanide elements of the Periodic Table between 57 and 71. These are known as the “rare earth elements.”

Samarium-cobalt was the first such material used in the early 1980s. The next material on the market was neodymium-iron-boron. Today, rare earth magnetic circuits produce a magnetic force more than 10 times that of ceramic magnetic circuits. Today’s rare earth magnetic circuits are 50% to 66% more powerful than early versions. They can develop an extremely high surface force to enable the magnetic circuit to remove very fine or weakly magnetic contamination such as rust, scale, or even work-hardened stainless steel from a product flow. High-strength rare earth separators are used by plastics processors requiring the highest levels of purity.

APPLICATION CONSIDERATIONS

Here are several factors to consider when choosing a magnetic separator for your process application:

•Temperature: Permanent magnetic materials lose strength when exposed to elevated temperatures. Some losses are reversible, so that when the temperature is returned to normal, the magnetic strength returns. Permanent magnets heated beyond certain temperatures (which depend on the specific material) may also suffer irreversible loss—a reduction in strength that cannot be recovered by cooling. When specifying a magnet application, it is important to note the ambient as well as any Clean-in-Place (CIP) temperatures to ensure a proper magnet design suitable for long-term separation performance.

•Flow rate: Magnetic separators perform best when the contamination is presented to the surface of the separator. It is best to select a magnetic separator configuration that provides for a thin “burden depth” (thickness of the material layer) over or under the magnet to ensure that the magnet will have the best opportunity to capture the ferrous contamination.

•Flow characteristics: Many products exhibit different flow characteristics when damp or moist. Are there large chunks that may plug an opening or gap in the separator? Will the product flow freely through the selected magnetic separator? For example, brown sugar with any significant moisture content will not flow between the tubes in a grate magnet assembly, although they may be positioned nearly 1 in. apart.

•Process issues: How will the material be presented to the separator? Is the material metered or do you need to handle surge flow? Can the system be stopped for cleaning or is a self-cleaning magnet required? Is access available for cleaning? Is there ferrous material in the area that may create a hazard for magnet handling? How much contamination is to be removed? And finally, what level of product purity is required?

TYPE OF MATERIAL PROCESSED

Assessing the material being processed is a key step in selecting the proper magnetic separator. Materials generally fall into three categories: dry, moist, or liquid. A wide range of product variation exists within each of these groups—depending, for example on particle size of solids and viscosity of liquids.

Dry, free-flowing, granular product: If the particles are small and free-flowing, a grate magnet may provide the best opportunity for the ferrous contamination to contact a magnet directly. Grates do the best job with vertical product flows, while plate magnets work well if the material is cascading down a chute. These product-cleaning methods require that the product flow be stopped when removing collected ferrous contamination from the magnet.

Pneumatic flows of free-flowing product work best with a magnetic “hump” configuration or radial field cartridge. These separators also require suspension of product flow for cleaning.

Drums, pulleys, and suspended magnets can provide for continuous automatic removal of tramp metal without needing to stop the flow and with little or no cleaning required.

Dry product with some bridging tendency: While grate magnets provide for very efficient removal of fine metallic contamination, they do not work if the material cannot cascade between the magnetic tubes. Plate magnets do not restrict the flow of material and will not contribute to bridging if installed beneath a sloped chute.

Magnetic humps are available for less-than-free-flowing products as long as the material will cascade down a sloped chute. Suspended magnets and pulleys may also work well if the material is conveyed with a belt conveyor or vibratory feeder.

Liquid or slurry products: Products in a liquid or slurry state require a magnetic trap. Traps are available in either a grate or plate type design. Many traps are built similar to grates in that tube magnets are arranged perpendicular to the flow inside in the body of a casting to “trap” any ferrous materials passing through. A U-Trap employs a flat plate magnet in a shallow body to minimize damage to the product flowing past. They are ideal for chunky-flow applications.

PLATE MAGNET DESIGNS

Plate magnets are used in the bottom of an inclined chute or suspended above a thin burden of material on a belt conveyor or stainless-steel vibratory feeder to remove occasional pieces of ferrous contamination. Plate magnets are simple and economical to install and good at removing occasional pieces of tramp metal.

Some ceramic magnet models are effective in removing relatively large ferrous objects such as nuts, bolts, staples, and welding rods from a dry product flow. Rare earth models will do a much better job on very fine or weakly magnetic contamination such as rust or scale.

In a typical chute installation, the magnetic contamination adheres to the magnet face while the product material slides across the face of the magnet. The magnetic field attracts and holds ferrous material until the plate is removed for cleaning. The magnet is usually hinged and swung away from the chute and cleaned manually.

Round pipe separators (RPS) are actually plate magnets with a fabricated transition from a round pipe to the rectangular chute that contains the plate magnet. The RPS consists of an inlet transition to match the existing pipe or tubing, a rubber deflector to “aim” the product against the plate magnet, then transitions back to the chute shape. The material flow must be stopped to clean the accumulated tramp metal from the plate magnet.

Hump magnets are similar to round pipe separators except that the fabricated chute utilizes two plate magnets instead of one. This extra plate effectively doubles the chances of collecting ferrous material. The hump consists of a dogleg chute that allows the product stream to cascade from one magnetic plate to another as material moves through the dogleg. Units are available for pressure, vertical, or horizontal pneumatic applications. The material flow must be stopped to clean each plate. Self-cleaning units are also available to cycle the plate magnet away from the flow so that a stripper may automatically remove the accumulated tramp metal from the plates.

Deep-reach separators use a plate-magnet-style circuit but incorporate it into a vertical chute. They work well when sticky products do not readily flow down sloped chutes or when headroom is at a minimum. Two large magnet assemblies are affixed to opposite sides of a stainless-steel chute and attract ferrous contamination as material flows by the chute. The magnetic circuit is designed for an exceptionally deep reach into the product flow, which makes these separators effective at removing large, chunky tramp metal.

GRATE MAGNET DESIGNS

Grate magnets consist of 1-in. diam. magnetic tubes in a grid formation designed to allow the feed material to cascade through the grate, effectively spreading magnetic protection through the cross-sectional area of a pipe, chute or hopper. As with plate magnets, ceramic models are effective in removing relatively large ferrous contamination such as nuts, bolts, or staples, while rare earth models are better on fine or weakly magnetic material such as rust or scale.

There are a variety of grate magnet designs for almost any application. The simplest of these incorporate a single-layer magnetic grid for use inside a hopper so raw materials must pass through the grates as material feeds from the hopper. Multiple-row units improve separation effectiveness. Some applications will utilize a single row of magnets and incorporate them into a grate housing assembly of the user’s design. Housings can also be fabricated to include one or multiple rows of magnetic grates with staggered magnetic tubes, depending on the level of protection required. These units are common for vertical chutes of free flowing materials.

Grate-housing designs may include a standard grate that is removed from the housing for manual cleaning. An easy-toclean grate design provides for a push/pull operation to strip accumulated tramp metal from the grates without physically handling the magnet. Rotating magnet designs are available for materials that bridge or do not flow well. Self-cleaning units are also available so that the cleaning process is automated.

PNEUMATIC LINE MAGNETS

The radial field (RF) cartridge magnet is ideal for pneumatic flows of any product typically conveyed with air from a tank truck or railcar. The assembly is designed to match the existing pipe and is then transitioned to a larger pipe that incorporates an enclosed magnet element. The material cascades around the magnet, and ferrous material collects on the magnet as it is conveyed through the assembly.

PULLEY AND DRUM MAGNETS

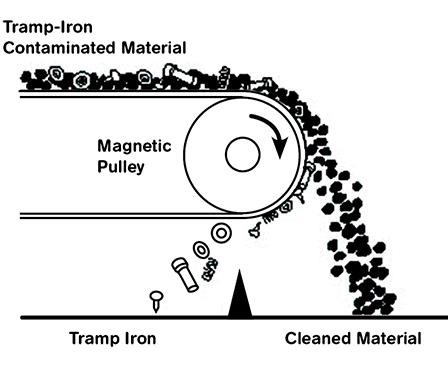

Magnetic pulleys replace standard conveyor head pulleys and effectively convert the conveyor into a self-cleaning magnetic separator. As the conveyed material passes the head pulley and discharges in its natural trajectory, the magnets “scalp” large tramp metal from the burden, then discharge it as the belt pulls away from the backside of the pulley.

One unique version of this system is used to separate the components of multi-layer or multi-material plastic regrinds. Eriez’s PolyMag system utilizes a magnetic additive that is added to one of the resins much like a colorant. When the regrind passes over the rare earth magnetic roll, the magnetic-additive-containing component is separated from the other component so that both can be recycled with minimal contamination by the other component.

Drum magnets are self-cleaning magnet assemblies that continuously remove tramp metal from a product flow. The magnet assembly is enclosed within a stainless-steel drum and fixed in position. The drum rotates around the magnet, conveying material through the magnetic field. Clean or nonferrous material cascades off the drum face while the magnetic material is drawn around the drum and discharged at the bottom. As noted for plate and grate magnets, drum separators use ceramic magnet circuits to remove relatively large ferrous objects from a dry product flow, while rare earth models are better suited to removing very fine or weakly magnetic contamination.

NONFERROUS METAL SEPARATORS

Eddy-current separators use a different approach to magnetic separation: They “repel” nonferrous metals. These powerful magnetic separators “kick-out” the nonferrous metallic products or contamination being conveyed while allowing other materials to continue in the flow. Eddy-current separator systems contain high-speed, powerful rare earth magnetic rotors and are available in a range of configurations. These often include vibratory pan feeders, adjustable splitters, high-speed conveyors, hoods, and even suspended magnets to remove ferrous metals that may also be present.

A variety of all-metal detector/separator systems are also available. They detect aluminum, brass, copper, mild steel, stainless steel, and other metals (magnetic or non-magnetic) and use various mechanisms to eject any detected metals. They use arrangements of transmitter and receiver coils that bracket the flow of material (or the transmitter and receiver can be integrated into a single unit). The transmitter coil emits a low-frequency electromagnetic field. This field will be perturbed by the presence of metal, which will absorb some of the energy by the generation of eddy currents in the metal. The receiver coils sense the change in the field and actuate some sort of mechanism to reject the contaminated feed material.

One version can be installed directly above the feed throat of an extruder or molding machine with an air-actuated slide and evacuation venturi to remove metal contaminants. This type is best suited for virgin materials with less than 15% regrind.

Another variety can be installed in conveying lines to detect and remove metals under free-fall conditions. Highly sensitive detectors can catch metals even when encapsulated in plastic pellets. And metal detector/separator conveyors can be used to protect shredders and granulators by cleaning the infeed material of metal contaminants.

Related Content

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)