HRSflow Opens Ultra-Modern Hot-Runner Plant in Michigan

Italian hot-runner firm establishes first North American production, focused on automotive.

In September, Italian hot-runner specialist HRSflow officially opened its first North American manufacturing facility in Byron Center, Mich., near Grand Rapids. More than 200 molders, OEMs, and other guests attended the event. The brand-new building occupies 40,000 ft2 and plans to add another 50,000 ft2 in the next three to four years are already on the drawing boards. The number employees would then more than double from the present 50 (and still growing).

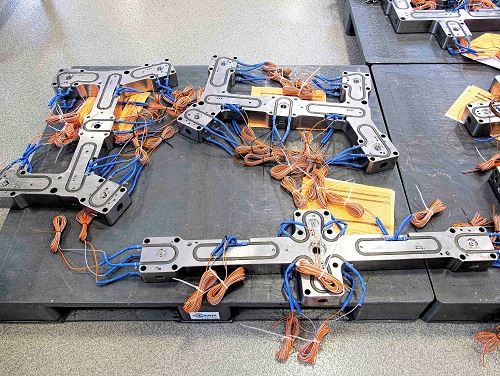

The plant has CAD/CAE design capabilities, three CNC milling systems, and three lathes, including a palletized system that can run load up to seven manifolds to run “lights out.” One lathe can run for two days unattended, thanks to an automatic bar-stock loader, auto tool changer, and six-axis robot that removes finished nozzles and places them in a storage rack. John Blundy, president of the new operation, says, “It’s the most modern, innovative plant in North America for producing hot runners.” Blundy is a well known figure in the field of injection molding, with 40 years of experience, 15 of them at Incoe. (For more details on the new plant, see blog post.)

HRSflow is a division of Italian moldmaker INglass S.p.A. It specializes in larger automotive appearance parts for lighting and instrument and door panels, fascias, fenders, and spoilers. Its flagship product is the FLEXflow servo-driven valve-gate system, which offers eight steps of freely programmable valve-pin position, speed, and acceleration. The results are said to be improved cosmetic appearance and elimination of flow “hesitation” lines while permitting reduced clamp force, part weight, and warpage. During the opening event, mineral-filled TPO rear spoilers were molded on the plant’s 1000-ton injection press (used for mold trials) with and without FLEXflow valve-pin control. Results in the accompanying table show the ability to use 20% lower clamp force while achieving 4.5% to 7.3% weight reduction. (For more details see this blog post.)

HRSflow has been represented in North America for sales, service, and engineering since 2001. “We nevertheless realized that only with local production facilities could we achieve the short delivery and response times and the overall flexibility that are needed, for example, in the automotive industry,” said Maurizio Bazzo, founder, president, and CEO of INglass. A goal for next year is reducing shipping time for standard components from 24 hr to 4 hr. HRSflow also manufactures in Italy and China.

Besides automotive, HRSflow also has a Multitech line of hot runners for high-cavitation, fast-cycle parts like closures and medical disposables. While HRSflow North America has sales specialists for Multitech, it will focus its manufacturing efforts on automotive for now. Manufacturing of Multitech systems here could be two years off, said Bazzo.

Related Content

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)