Hybrid Printers & Inkjets Made News at NPE

Processors looking for something new at the NPE 2009 show in Chicago found “hybrid” multi-process printers, high-quality inkjets, and other advances in printing on plastic parts.

Processors looking for something new at the NPE 2009 show in Chicago found “hybrid” multi-process printers, high-quality inkjets, and other advances in printing on plastic parts. Innovative corona and plasma treaters were also featured.

VERSATILE PRINTERS

An eight-color hybrid printing machine for 3D items such jars, containers, and flexible tubes for personal-care products was introduced by Germany’s Isimat, represented here by Isimat North America. The TH 8130 combines the advantages of flexo for half-tone printing of photo-realistic images plus silk-screen printing of solids and texts. This is said to significantly increase the efficiency of the tube decoration process, eliminating the need for offset printing in one machine and screen printing in another. The unit’s flexo printing station features a special servo-driven mechanism that reportedly keeps the distance between cliché roller and tube constant during printing by tracking the run-out of each mandrel. This eliminates distance variances that leave non-print areas on the tube.

Italy’s Omso launched its new automatic Servotube 137 machine with a flexible print configuration for decorating cylindrical tubes by silk-screen and/or flexo technology. The unit has 24 servo-driven mandrels and can reach speeds up to 150 pcs/min, depending on the diameter and length of the tube. The standard version has six print stations with the option of an additional station for lacquering or auxiliary operations. Registration between colors is said to be within ±0.02 mm, which allows for half-tone decorations.

A digital flatbed inkjet printer launched by Screen USA, part of Japan’s DaiNippon Screen Mfg. Co., is said to excel in sharp image reproduction, high-print density, and front-to-back registration. The Truepress Jet650UV is reportedly comparable to a six-color silk-screen printer but is aimed at high-quality printing rather than standard high-volume silk-screened products like T-shirt bags or bottles. Its versatility is suited to products ranging from vehicle dashboards and instrument clusters to appliance control panels, cellular phone cases, medical equipment, and custom packaging. It boasts a rich variety of realistic tones, defined gradients, translucent print for backlighting, and crisp text.

Truepress Jet650UV has a maximum print area of 25.3 x 23.3 in. and speeds up to 201.5 in.2/min. It has a maximum resolution of 2400 x 2400 dpi and eight-level grayscale inkjet heads that can vary the droplet size from 6 to 42 picoliters. The unit comes standard with UV-curable CMYK inks. A CCD camera detects the media position and automatically adjusts the alignment. Also featured are a temperature-control system that keeps inks at a uniform temperature and a media cooler that prevents heat emitted by the UV lamps from distorting the plastic substrate.

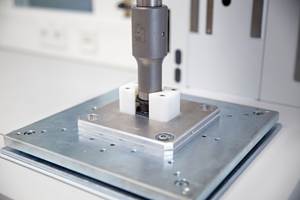

ITW Trans Tech showcased its new InDec V2 Series direct-to-substrate inkjet printers that combine high precision with the flexibility of digital printing. It supports up to six fluids, including white and clear options. Print area is up to 52 x 44 in. and user-selectable resolution is up to 1200 dpi in process or cross-process directions.

A new universal screen printer for cylindrical, slightly conical, oval, and flat containers was shown by Kammann USA. Model K-15F has a compact design based on a round indexing table with 16 carrier stations for up to six-color decoration in one pass. Print-length capacity ranges from 40 to 280 mm and output is up to 5400 cycles/hr.

This printer boasts reduced setup cost due to simplified tooling and fast changeovers. Servo-motor control provides constant height of screens and UV lamps, as well as article diameter adjustment and oval-printing motion. Squeegee heads have pneumatic control, vertical liftoff, and spread and adjustable-angle capability. The unit also offers selectable register direction and UV lamps with a central exhaust system. permits Automatic setting of screen stroke, article rotation, and squeegee movement is based on operator input of article parameters like diameter, taper, radius, and print image length.

Apex Machine exhibited what was called a “breakthrough” in dry-offset printing of up to six colors. The new FlexApex system features special print heads that can deposit much heavier ink films than was previously possible. FlexApex is reportedly suited to applications where rotary pad printing with solvent inks has been the only available technology that offered sufficient ink lay-down and operating speeds. The solvent-free, UV-cured FlexApex offset process is said to be significantly more economical.

SURFACE TREATMENT NEWS

Germany’s Kalwar Group, represented here by Lectro Engineering, featured its new Calvasol series of corona treaters, which can apply coatings of antifog, antistat, or UV stabilizer onto the film during the corona treatment process. Elimination of a secondary coating step is said to result in up to 40% higher line speeds. Other advantages include formation of a reactive layer in the submicron or nanometer range and minimum use of reactive substances. Calvasol eliminates need for additives that require humidity to migrate throughout an extruded film.

Plasmatreat North America showcased its new Openair Plasma treaters for use in multi-component injection molding and coextrusion. According to the company, rigid/flexible combinations of low-cost materials such as PP and TPU were not possible previously because the TPU did not adhere to the PP, forcing manufacturers to design components with more expensive rigid resins such as PC/ABS. Plasma pretreatment makes it possible to mold parts with a thin, soft-touch TPU skin while providing rigidity with low-cost PP.

The atmospheric-pressure Openair Plasma technology has been shown to achieve good bonding between PP and nylon, PE and nylon, nylon 6 and 12, PBT and nylon 6, and between unmodified TPEs. Pretreatment can take place directly in the mold or when transferring parts to another mold.

3DT featured its PlasmaDyne self-contained floor-standing plasma treater that integrates easily into new or existing extrusion lines. This unit is said to deliver a treatment five-to-six times stronger than earlier models within a proximity of 1 in. or less. It allows for line speeds of up to 100 ft/min.

Related Content

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

Read MoreOMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

Read MoreMinnesota-Based Initiative Launches Circular Economy for Flexible Films in Upper Midwest

MBOLD coalition unites leading global businesses and research institutions to catalyze a regional circular economy for flexible films and packaging materials.

Read MoreHot Wash Systems for Recycling Polyolefins

Herbold can configure wash plants for polyolefins that can produce high-quality, food-grade recyclates.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.png;maxWidth=970;quality=90)

(1).png;maxWidth=300;quality=90)