Induction Barrel Heating May Use Up to 70% Less Energy

Dramatic energy savings, greater reliability, and much faster response than conventional heater bands are being claimed for an alternative that will debut at next month’s K 2007 show in Dusseldorf.

Dramatic energy savings, greater reliability, and much faster response than conventional heater bands are being claimed for an alternative that will debut at next month’s K 2007 show in Dusseldorf. The new Indx non-contact barrel-heating system from Xaloy Inc. utilizes electromagnetic induction. That’s an old and well-known principle, used to heat large industrial furnaces, special machines for injection molding molten metal, thermoset molds, and even some Japanese hot-runner nozzles. But it’s quite new for heating barrels of plastics molding and extrusion machines.

Xaloy’s Indx system turns the steel barrel itself into a resistance heater by generating electrical eddy currents in the metal near the outer surface of the barrel tube. Those eddy currents are induced by electrical current passing through a cable wrapped in a continuous coil around the barrel but not touching it. Although it costs more initially than heater bands, induction heating reportedly pays for itself in several ways—and can do so quite quickly, depending on machine size.

What took it so long?

Why hasn’t induction barrel heating appeared before now? According to Indx business manager Bruce F. Taylor, early efforts to commercialize induction heating for plastics utilized bulkier, lower-frequency, higher-amperage hardware of the type typically used for induction furnaces. These generate lots of heat but are too costly and inefficient in energy consumption, Taylor says. Much more efficient higher-frequency, lower-amperage inductive circuit technology, such is used in today’s variable-speed AC drives, is a recent development whose cost continues to drop. With inductive hardware costs falling and energy prices rising, induction heating makes better sense now than ever before, Taylor claims. He also notes that earlier attempts to use induction barrel heating put the induction coils in direct contact with the hot barrel, which prevented the use of more efficient inductor coils and raised the coils’ electrical resistance, further reducing their efficiency. Also, heat generated in the barrel was allowed to escape wastefully into the surrounding environment.

The Indx system (patents pending) avoids these problems. Barrel heat is retained by means of a foam insulation material that is vacuum formed into half-cylinder sections. Each section has grooves or channels in the outer surface to hold the special high-frequency inductor cable. The insulator sleeves are placed around the barrel and the cable is wound into the spiral grooves, holding the two insulator halves together, though Xaloy also supplies Velcro-type fasteners. Each barrel heat zone takes two insulator half-sleeves and an inductor cable with snap-in connectors on the ends. Installation is said to be much quicker and simpler than with heater bands, since there are no more relays and no wiring to the cabinet other than the snap-in connector cables supplied by Xaloy. Molders can even keep a spare barrel already outfitted with Indx sleeves and heaters. Once the barrel is in place on the machine, just snap in the electrical connection and it’s ready to go.

How much better?

Xaloy’s laboratory measurements indicate that the heating efficiency (relative to energy consumed) of typical mica band heaters at the 390 to 575 F (200 to 300 C) processing range common in injection molding is likely to be only 40% to 60%, while a ceramic band may be 10% to 15% higher. The remaining energy is wasted by radiation and convection to the surrounding environment. What’s more, a new mica band loses about 10% of its initial efficiency after the first 6 hr of use because it darkens, raising its surface emissivity and consequent radiation losses. At higher barrel temperatures for engineering resins, efficiency drops even more.

In contrast, Xaloy measures induction heating efficiency at about 95%. Radiation losses are minimized by the insulating sleeves, which rise to a temperature of around 120 F during operation, Taylor says. The low-resistance induction coils remain cool enough to touch.

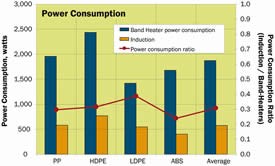

Xaloy tested the Indx system against band heaters on an 85-ton Toshiba injection press with a barrel having an ID of 36 mm and OD of 90 mm and three heating zones. Each zone used either four mica band heaters consuming a total of 3.2 kw or an induction coil driven by an inverter that delivered 2 kw. A 40-g part was molded from a range of resins using a 30-sec cycle time. The same zone-temperature setpoints were used with both heater types. Current draw and barrel temperature were monitored at 1-sec intervals, and melt temperature was sampled at the nozzle to ensure consistent melt quality. The results for four resins are shown in Fig. 1. Induction heating averaged only 30% as much power consumption as the mica bands.

Taylor also says induction’s much more uniform heat distribution along the length and around the circumference of the barrel, and its rapid response translate into more uniform barrel temperatures and thus potentially improved quality of plastic products.

Xaloy explains this in terms of the thermal mass of the band heaters. Barrel temperature can rise only when the band heater is hotter than the barrel, and the barrel can cool only when the band heater is cooler than the barrel. Since band heaters have significant thermal mass (heat retention), the heater itself requires time to heat up or cool down. Induction coils, however, add zero thermal mass to the barrel, so the only limitation is the speed of heat conduction through the steel of the barrel wall. What’s more, Xaloy’s research shows that induction heating acts directly on the steel to a much greater depth than would be expected from theory, so less time is required for conduction.

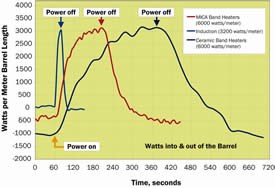

Xaloy demonstrated the differing in responsiveness of induction vs. band heaters in steady-state plasticating of resins on a barrel segment (38 mm ID, 89 mm OD, 368 mm long) representing a single heat zone, mounted on a benchtop. Barrel temperatures were measured using six pairs of thermocouples installed at six incremental depths from the outside surface to the bore. Power consumption and temperature were measured 10 times per second. Figure 2 shows that heat input to the barrel reaches a maximum almost instantaneously (i.e., within 15 sec) when the temperature controller directs power to the induction heater and drops to zero just as fast when power is turned off by the controller. In comparison, it took more than 2 min for the heat input rate to peak using mica heater bands and about 5 min with the more massive ceramic heaters. Likewise, when power was turned off, it took over a minute for mica bands to cease any heat input to the barrel and about 3 min for ceramic heaters.

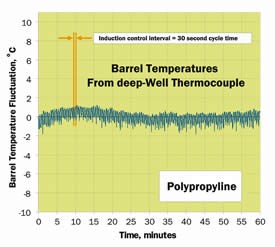

What this means on a real injection machine appears in Fig. 3. It shows very slight barrel-temperature fluctuation with induction heating, as measured and controlled with a deep-well thermocouple close to the barrel ID (and to the melt). Each time a new shot of cold material entered the barrel, the deep-well thermocouple sensed the cooling of the inner barrel wall and called for more heat, and then cut power to the induction coil once the deep-well setpoint was reached. Using simple auto-tune PID temperature controls, the induction heaters were so responsive that the controller was able to perfectly synchronize the temperature-control interval with the 30-sec machine cycle.

In experimental trials with heater bands, the same control setup produced wide swings in barrel temperature, five times larger than the fluctuations with induction heating, and occurring over more than a dozen cycles. To be fair, Taylor notes that heater bands on injection machine barrels are not typically controlled in this manner. Precisely because external barrel heating with heater bands is too slow in responding to temperature measured deep inside the barrel, most heater bands are instead pulsed on and off every few seconds to provide constant heat input to the barrel wall. Temperature sensing with heater bands normally uses only shallow-well thermocouples nearer the barrel’s OD that are insensitive to rapid temperature fluctuations near the barrel ID. In other words, Taylor explains, typical injection-machine temperature controls don’t look at what is happening deep inside the barrel close to the melt channel, precisely because they can’t respond to it effectively in any case.

Taylor is developing more data to show what really happens to deep-well barrel temperature using heater bands and typical control schemes for those heaters. In one customer trial on a 1000-ton machine with a 3.5-in. barrel ID and 8-in. OD, with the machine control cycling the induction heaters on and off every 6 sec just as it does with band heaters, the shallow-well thermocouples detected only a few degrees oscillation during the 92-sec molding cycle—but the deep-well thermocouples detected five times greater oscillation in temperature due to the entry of cold resin for each shot. Taylor is confident that further tests will show similar wide swings in barrel ID temperature with band heaters.

The greater responsiveness of induction heaters is especially valuable in cyclical processes—which is why Xaloy is first marketing it to injection molders. In the future, Xaloy plans to adapt the Indx system for extruders, blow molders, extrusion dies, rolls, and other plastics equipment. (Extrusion has the added complication of requiring a means of barrel cooling.)

Taylor says induction provides faster startups by bringing the barrel up to temperature two to three times faster than band heaters. And during downtime, the Indx insulation is more effective than barrel blankets at retaining barrel heat.

No more heater burnouts

While heater burnout is a common problem among molders, Taylor says, inverters are highly reliable in continuous use and he expects no failures of the induction cable. He adds that molders frequently operate unknowingly with failed heater bands, and that it can be difficult and time consuming to identify which band has failed. This can lead to quality problems, he says, and higher maintenance costs from uneven wear of screws and barrels.

He also notes that individual heater bands typically heat only 50% to 80% of the barrel circumference, depending on size. Therefore, users need to know not to install the bands with their latches and terminals lined up in parallel, or uneven barrel temperature and screw/barrel wear are likely to result.

What about the cost?

At present manufacturing volumes, the Indx system costs roughly five times as much initially as conventional heater bands, though that differential could come down later on. That makes the target market for Indx among medium-size to large machines using screws of 50 mm or larger—i.e., of 400 tons or greater clamp capacity. Taylor says induction barrel heating can pay for itself within 18 months in energy savings alone for a machine with a 70-mm screw operating at high throughput and using electricity at 10¢/kwh. He notes that the higher the machine’s throughput (“the harder it’s working”), and the bigger the barrel, the greater the savings should be.

Added to that, he says, are potential savings from reduced wiring on new machines, less frequent replacement, no need to keep thousands of dollars’ worth of spare heater bands in inventory, reduced downtime, and even improved product quality.

Incidentally, Taylor coauthored a paper on the induction heating system with Xaloy’s Timothy W. Womer and Robert Kadykowski (“Efficiency Gains and Control Improvements Using Different Barrel Heating Technologies for the Injection Molding Process”) at this year’s SPE ANTEC meeting.

Related Content

Captive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreHigh-Temperature, Low-Flow Indicator for Mold-Cooling Applications

Burger & Brown Engineering has released a new high-temperature low-flow indicator to monitor flow inside critical, restricted cooling paths such as those with bubblers or baffles.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=970;quality=90)