Infrared Crystallizes and Dries PET Faster and with Less Energy

In the search for ways to dry hygroscopic resins faster and more efficiently, infrared energy is an approach that many dryer makers find intriguing and potentially promising.

In the search for ways to dry hygroscopic resins faster and more efficiently, infrared energy is an approach that many dryer makers find intriguing and potentially promising. A few have tried their hand at building IR dryers, with mixed success. Now Novatec Inc. has begun making an IR crystallizer/dryer for PET regrind that is said to overcome limitations of earlier designs.

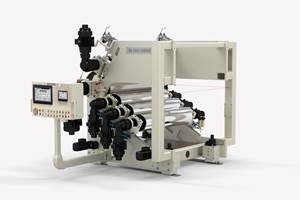

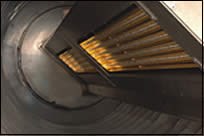

Novatec’s Infrared Rotary Drum (IRD) unit is produced and sold under exclusive license from Stricker IRD Patent GbR in Germany and UPM Holdings Ltd. in the U.K. It is a slowly turning cylinder with a wide, shallow spiral channel on its interior, as well as paddles that stir the PET regrind as the drum turns. The helical channel gradually conveys the material along the axis of the drum. A stationary bank of IR emitters hangs in the center of the drum and a stream of ambient air flows through the drum to carry off moisture that escapes the hot resin. Resin passes through the drum in 8 to 14 min. In that short period of time, the PET is not only fully crystallized but is also dried to a substantial degree, according to dryer sales manager Mark Haynie. This is what distinguishes the IRD from conventional hot-air crystallizers, he says.

Because some additional drying is typically required–especially if the regrind is to be used in bottle or preform molding, Novatec pairs the IRD with a conventional twin-bed desiccant dryer to finish the job and to serve as a buffer hopper to keep the resin dry until it is processed. Time in the buffer hopper also results in a more uniform resin I.V., Haynie notes.

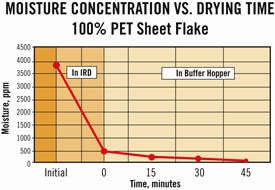

He says the residual amount of drying required after crystallization can be accomplished much more quickly and in a much smaller desiccant dryer than would otherwise be needed. According to Haynie, around 15 min in the IRD and another 45 min in the dryer is sufficient to finish the job, as compared with a typical hour in a conventional crystallizer plus 4 to 5 hr in a desiccant dryer. Not only is the IRD/desiccant crystallizer/dryer system faster than the industry standard, but Haynie says it also uses much less energy. Capital cost is about the same.

Haynie says one reason why the IRD system is faster is that the IR energy can penetrate up to 5 mm into the PET particles. Other dryer makers have disputed this, claiming that IR heats only the surface of the PET. However, Haynie replies that the efficiency of IR heating depends on the wavelength used and that the short IR wavelengths (1 to 2 microns) used by Novatec’s IRD are tuned specifically to the absorption spectrum of both PET and water, and also penetrate more deeply than other wavelengths.

While some earlier IR drying systems for PET were plagued by dust collecting on the heaters and drum walls, Haynie says this has not been a problem with the IRD, which turns at only 1 to 1.5 rpm.

Customer validation tests

Novatec has performed a number of IRD test runs for large PET bottle molders and sheet extruders. Those tests were conducted at Novatec’s new Drying Technology Center using an IRD-500 model, rated at 500 lb/hr, plus a twin-bed dryer. Because the IRD unit holds a small inventory–only 125 lb in this case–the system requires only a 300-lb buffer hopper on the desiccant dryer. According to Haynie, a conventional system, in which most of the drying takes place in a desiccant dryer below the crystallizer, would require a 2500- to 3000-lb drying hopper to match the 500-lb/hr throughput of the IRD/dryer system.

| TABLE 1—CRYSTALLIZING & DRYING 100% PET SHEET REGRIND FLAKE (Customers’ Target: 200 ppm) | ||

| Moisture Content, ppm | ||

| Customer A | Customer B | |

| Initial | 3838 | 2218 |

| After IRD Crystallizationa | 493 | 218 |

| In Buffer Hopper | ||

| 15 min | 231 | 208 |

| 30 min | 158 | 84 |

| 45 min | 91 | — |

| aAbout 14 min. | ||

Table 1 shows results of test runs of 100% sheet flake regrind supplied by two different customers. In both cases, fairly “wet” regrind was crystallized in about 14 min in the IRD-500 and about 90% of the moisture was removed at the same time. The customers specified a target moisture content of 200 ppm (0.02%) as suitable for reusing the flake in sheet extrusion. The table shows that flake right out of the IRD unit was close to the target level and reached the target within 15 to 30 min in the drying buffer hopper and 30 to 45 min total processing time. The IRD operated at 190 to 230 F (depending on the run) in the first heating zone and 330 to 375 F in the second zone. The twin-bed dryer used 350 F drying air.

Table 2 shows results of two similar tests on 100% PET bottle regrind flake supplied by two customers. In these cases, the customers’ target moisture content was 50 ppm for recycling the PET back into bottles. This target was achieved after 30 to 60 min in the buffer hopper and 45 to 90 min total processing time. The final I.V.’s were well above the minimum of 0.69 dl/g recommended by PET resin suppliers for bottle uses. The IRD was run at 250 F in the first zone for both tests and at 350 to 375 F in the second zone. The Buffer hopper was at 350 F.

Estimating energy savings

For these same customers, Novatec estimated energy costs for crystallizing and drying regrind using the IRD and conventional systems. For 100% bottle regrind at 2100 lb/hr, total estimated savings were 45%. At 4000 lb/hr, the savings were 54%. That is based on estimates that the IRD dryer uses 33% less energy than a conventional crystallizer, while the buffer hopper dryer uses 74% less than the larger companion dryer that would ordinarily be used.

| TABLE 2—CRYSTALLIZING & DRYING 100% BOTTLE REGRIND FLAKE (Customers’ Target: 50 ppm) | ||||

| Moisture, ppm | I.V., dl/g | Moisture, ppm | I.V., dl/g | |

| Customer C | Customer D | |||

| Initial | 1997 | NA | 5415 | NA |

| After IRD Crystallizationa | 101 | 0.759 | 587 | 0.497 |

| In Buffer Hopper | ||||

| 15 min | 76 | 0.786 | 246 | 0.608 |

| 30 min | 48 | 0.766 | 85 | 0.719 |

| 45 min | 53 | 0.820 | 70 | 0.798 |

| 60 min | — | — | 50 | 0.800 |

| aAbout 14 min. | ||||

For 100% sheet regrind at 3000 lb/hr, the total savings were 35% and rose to 56% at 4000 lb/hr. However, if the dryer accompanying the IRD unit had gas instead of electric process heating (with electric regeneration heat), the total energy cost savings at 3000 lb/hr would balloon to 49% less than the electric-heated conventional system.

Now, if the conventional system used gas heating for both the crystallizer and dryer process heating (not regeneration), the cost would be very close to that of the all-electric IRD/buffer system at 3000 lb/hr. And if gas were used on both the conventional and IRD/buffer systems, the total energy cost would be only 21% less for the infrared alternative.

Because the capital cost for the infrared and conventional crystallizer/dryer systems are comparable, Haynie says the IRD system makes economic sense for PET sheet producers and others that uses more than 10% regrind, which requires a separate crystallization step. However, bottle makers that use less than 10% regrind can crystallize that amount in a drying hopper without using a separate crystallizer. For such users, nearly doubling the capital cost to purchase an IRD/buffer system would be a questionable choice, since the payback period would be as long as two years.

More than 50 IRD systems have been built by other licensees in Europe and Japan. Novatec offers the system in standard sizes from 200 to 4000 lb/hr and aims to test the IRD with resins other than PET.

Related Content

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreDeDuster Systems Cleans Up rPET Sheet

rPlanet cut its gel count drastically—allowing it to sell more sheet at prime prices—after installing a DeDuster system.

Read MoreRead Next

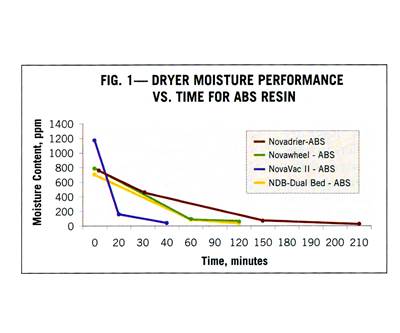

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)