INJECTION MOLDING: Another Way to Deal with Regrind

You can run into a lot of problems molding parts from a blend of regrind and virgin material. Might you be better off using 100% regrind?

The most important variables in molding are those that cause downtime and rejects if not handled properly. The amount and quality of regrind used in the process is one of these. Getting the most production from your purchase of resin requires appropriate use and care of regrind. To start, let us define “regrind” to be sure we all are on the same page, as there is no standard definition.

Regrind is material that has been processed at least once before, with the sprue, scrap, etc. subsequently ground or chopped. Note that even what most consider “virgin” resin may have one or more processing histories, as it was compounded and pelletized when made. Virgin resins can have additional process history, as additives such as color, fillers, stabilizers, lubes, etc. require a second compounding step. This “compounding” may be done by the resin supplier or at a separate compounding facility.

As a result of these processing histories, the polymer may experience degraded physical, chemical, and flow properties. As fellow Plastics Technology columnist and materials expert Mike Sepe often states, one of the first issues to check if you have questions about resin quality is length of the polymer chain or degradation of the molecular weight. This is done via a melt flow rate (MFR) test. If the chains are broken, MFR will increase in neat resins. Glass-filled polymers are a special case, as the glass fibers are broken during processing and special rules apply.

CAN MY REGRIND BE BLENDED?

What causes molecular-weight degradation is important, but not today’s topic. This is the question I want answered: Is the regrind acceptable for blending? If you chopped the chains—for example, by processing wet material that you thought was dry—you are in trouble (hydrolysis) and you should not blend this material with virgin. While most processors say they can tell if the resin is wet by the appearance of the melt or part, unfortunately they are wrong. Water is consumed by the hydrolysis reaction and parts will look and perform fine at room temperature.

Keeping the polymer chains long is just the beginning. Contamination is perhaps the biggest single problem with regrind. It gets contaminated with other resins, color, dirt, fines, metal, etc. There are plants that have huge quantities of regrind they know is contaminated and therefore unusable, but it stays on the books as “worth something.” The regrind sits there taking up valuable inventory space. (I wish the financial folks would pay as much attention to this fiasco as they do to “just-in-time” part inventories.)

Other resin/regrind complications can be loss or consumption of additives, such as mold release, antioxidants, acid scavengers, and antistatic agents during previous heat histories, along with color degradation, fiber-length reduction, over-drying etc.

WHAT LEVELS CAN BE USED?

Last but not least, we need to discuss regrind use level. How much is allowed, and what is actually being used at the press? In medical applications, the typical answer is none. The industry range is 0 to 100%. In addition, the target level may be one number, while the actual level being used is often a very different number. Just because you are using state-of-the-art weigh blending does not guarantee you are at the targeted level of regrind. What is your strategy for ensuring the target regrind level?

To develop a strategy and optimize the value of regrind, it is important to know the complications involved. Appropriate shop-floor procedures and discipline must be in place to avoid catastrophes. The list of complications is significant and there are subtleties within each:

• Tracking and documenting the actual level of regrind in a part.

• Degraded polymer in the regrind.

• Broad range of granule sizes in the regrind. Should you re-pelletize? It is extremely difficult for any injection molding screw to uniformly melt a wide range of particle sizes or shapes.

• Contamination from other plastics, colorant carrier, metal, wood, dirt, cardboard, etc. How much metal has plugged your hot tips? It does not take much to foul up the system, and after blending at any percentage it never leaves the system unless you sell all the regrind you have.

• Excessive fines in the regrind. Fines are a known to cause black or white specks.

• Processing variations due to the foregoing issues. These will be random and will be difficult for the processor to catch and accommodate.

If you are blending regrind with virgin you must contend with all of these issues. They might be possible to deal with on paper but nearly impossible to control on the production floor. For instance, how do you test to verify that the regrind is good, not contaminated or degraded? It can be done, but I have yet to see it truly implemented; and then there is the cost.

Bottom line: If the regrind is good then why blend it? If the resin regrind is not good why blend it? When you blend regrind with virgin you’re opening the door to a variety of problems: It’s hard to track; there’s no way of dealing with contamination; and there is the question of process stability as various percentages of regrind go through your presses.

AN ALTERNATIVE APPROACH

So, instead of blending regrind with virgin and encountering all the above problems, evaluate using 100% regrind. Store the regrind until all the virgin resin is consumed. Then feed regrind at 100%, after removing fines. The benefits of this approach are:

• There is no question about amount of regrind or if it is

properly blended.

• If there is polymer degradation, the machine will tell you, providing you are using velocity control and watching actual pressure at transfer. Broken polymer chains will show up as lower pressure at transfer as the velocity control maintains the same fill time.

• Range of granule size may still be an issue but may be corrected with processing adjustments.

• Possibility of contamination still exists, but this strategy is self-purging; the contamination will never be blended with good material. In addition, you can now implement strategies such as using only virgin with hot runners to prevent plugging of tips, and regrind would be used only in cold-runner applications.

• Excessive fines are still a potential problem, but you can add a deduster.

• Tracking the regrind becomes simple. Parts are labeled with the resin lot number and the number of passes of the regrind used. If parts made with regrind are bad or contaminated, they can easily be identified by pass number, pulled from inventory, and discarded. Chances of contaminating virgin resin become very low.

• It’s possible to test a worst-case scenario. Make parts from virgin material, then make another batch of parts after five regrind passes. Test their properties and compare. If all properties are good, use only a maximum of three passes to provide a safety margin.

For example, if you are processing a 1000-lb batch with a 20% scrap rate, on the first pass you’ll generate 200 lb of scrap; on the second pass you’ll make 160 lb of good parts and 40 lb of scrap; and on the third pass you’ll get 32 lb of parts and 8 lb of scrap. If contamination occurs, you only toss out the pass that is contaminated, not the whole production run. Sell the final 8 lb of scrap.

• Capital costs are lower because you do not need to buy blending equipment.

• As for physical properties, a study done by Sue Janicki et al. presented at SPE ANTEC 1992, The Material Cascade: An Alternative Form of Regrind Utilization, provides data showing excellent retention of physical properties after five 100%-regrind passes.

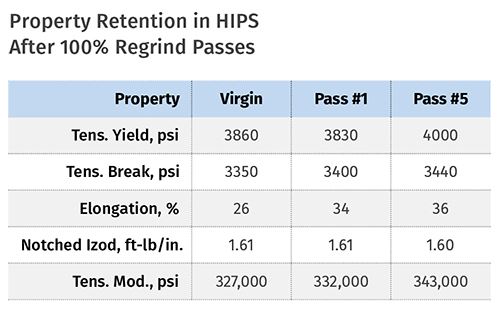

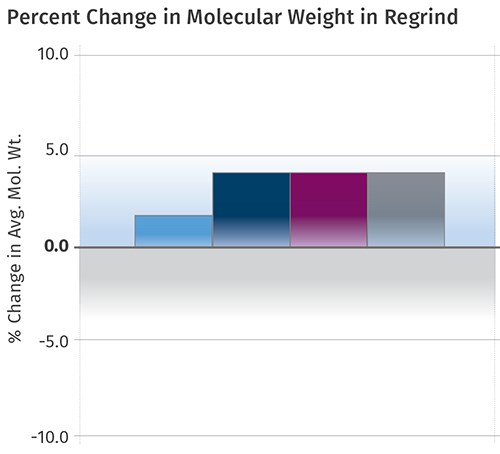

Some property-retention data from that study are provided in the accompanying table and graph. The table on p. 38 shows outstanding property retention in HIPS after the fifth regrind pass. The graph on p. 39 shows apparent increases in molecular weight (MW) for HIPS, ignition-resistant PS (IRPS), and polycarbonate (PC).

The MW increases are not real, however, as the data is only for average molecular weight. What the data shows is that with processing, the low-MW fractions volatize and are removed, hence the average MW moves up. (Interesting fact: Removing these low-MW fractions actually improved the ignition resistance of the PC.)

Of course, there are issues with using 100% regrind. Certain resins or colors may have processing issues, particularly resins with glass fibers. Processing glass-filled resins is known to reduce fiber length and this will reduce physicals.

You may have to get UL testing done on parts from 100% regrind. That’s costly, yes, but my bet is you already have that money tied up anyway in regrind inventory you cannot use.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)