Injection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

One of the most important of the hundreds of details involved in the injection molding process is the non-return valve, or check ring. There are various versions: three-piece, four-piece, full-flow, ball-check, etc. In more recent years, sliding- and locking-ring types have been added to the list. Which one is right for you? They all have their issues, and the focus here is on the issues between sliding- vs. locking-ring types. The terms “non-return valve” and “check ring” will be used interchangeably, for both terms are common in the injection molding community. First, what is the purpose of the check ring and how does it work?

The purpose of the non-return valve is to ensure molten plastic flows in only one direction. It is a one-way valve. It is supposed to act like a plunger seal in a syringe. Its function is two-fold: During screw rotation, plastic melt is pumped through the non-return valve by the metering flights of the screw. Molten plastic is forced through the non-return valve to develop the appropriate shot size. The pressure required to do this is determined by the back pressure set on the machine. Back pressures are typically 500 to 750 psi (34–52 bar) plastic pressure for non-filled resins. For glass-filled or resins sensitive to degradation, lower back pressures are recommended.

How well the check ring functions to prevent backflow determines the consistency of shot size and cushion.

Once the shot size is established and the mold is closed, nozzle-contact force is developed and injection of the plastic begins. As the screw starts moving forward, the non-return valve seat mates with the ring to make a seal to prevent molten plastic from flowing back over the flights of the screw. The pressure on the check ring and seat can be 20,000 to 45,000 psi (1380–3102 bar) as plastic is injected into a thin-walled part. Two seals must be made—one between the ring and the seat of the valve and another between the ring and the barrel wall. The seal between the ring and the barrel wall is accomplished by having a very close fit or tolerance between the ring and the wall.

The seal between the ring and its seat depends on perfect mating between the ring and seat. The molder does not want any plastic to backflow. Sounds simple enough, but under high pressures and normal molding conditions there can be some major problems.

These can include:

- Unmelted or partially melted pellets blocking proper mating of ring to the seat.

- Contamination, such as bits of metal and other solids, blocking proper seating or mating of the valve.

- Valves with large mating areas to their seats. Good seals are not made across a large surface area; small contact areas are superior.

- Valve wear. This is a high-wear component and wear is not easily evaluated without pulling the screw and tip.

- Viscosity of the polymer.

- Diameter of the barrel or size of the screw.

How well the check ring functions to prevent backflow deter-mines the consistency of shot size and cushion. Since there are two definitions for cushion, here it is defined as the position of the screw at the end of second stage or pack-and-hold time. How well the non-return valve functions plays a major role in producing consistent parts. Ideally you want to inject the same amount of plastic into every shot.

There are quite a few machines in plants today—for making small parts in particular—that have no check valves at all. These are two-stage presses where material melted in a small barrel with a fixed screw is fed to a plunger or shot pot, where a precisely fitted piston acts as a plunger that injects the plastic into the mold. There is one drawback: The nozzle is longer and has a larger pressure loss.

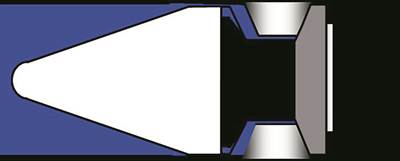

If we understand the mechanics of the check valve, we can now evaluate the sliding- vs. locking-ring issue. With a sliding-ring check valve, the ring does not rotate with the screw during plastication or screw recovery. It only slides backward during screw rotation and forward during injection (Fig. 1). With the locking-ring valve, the ring rotates with the screw during plastication and moves forward during injection (Fig. 2). They perform the same function, except that the sliding ring does not rotate and the locking ring does rotate during plastication.

The locking-ring style appears to dominate the market. My question is, why?

My view is that most molders believe that locking rings make a better seal, leak less and last longer. But where is the data? What is the cost? The locking-ring valve shown in Fig. 3 has been in use about 2000 hr. Note the scoring and scratches both circumferentially due to rotation and horizontally. Imagine what the inside of the barrel must look like. Is there any doubt that the barrel needs to be replaced too? What is only partially shown is the carbon buildup on the flights of the screw. Three flights of the metering section were nearly full of carbon and glass fibers. In this case, I contend that the locking teeth are partially blocking the forward flow of plastic.

In an article I wrote for the August 2017 issue of Plastics Technology (“Time for Another Look at Non-Return Valves”), I voiced my concerns, and Fig. 3 provides some evidence those concerns are real.

The locking-ring style appears to dominate the market. My question is, why?

Can you find sliding-ring valves this scarred? Probably, but after far more machine time and great abuse. Do sliding-type rings wear? Yes of course, but they are far less likely to cause barrel damage. As for better sealing, the industry needs to evaluate stepped-angle and radiused seats. While both are better than standard near-mating-angle valves, one study I have seen shows an 85% improvement for radiused seats over near-mating-angle valves.

Bottom line: I am not a fan of locking-ring check valves and suggest you stay away from them. Granted, we need some head-to-head comparisons with solid data to provide the facts. However, Fig. 3 speaks volumes. How much will it cost to replace the barrel?

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com; scientificmolding.com.

Related Content

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreRead Next

Injection Molding: Time for Another Look at Non-Return Valves

First and foremost, they must seal properly, and check valves with stepped angles or radiused seats perform the best.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More.jpg;width=70;height=70;mode=crop)