K 2004 News Preview: Compounding

Compounding news at the K Show includes the use of alternative motors to save space and raise output on twin-screw machines.

Compounding news at the K Show includes the use of alternative motors to save space and raise output on twin-screw machines. You’ll also see radical redesigns of a couple of high-end corotating twin-screws to lower their cost with-out losing much performance.

Driving innovation

One of the more interesting motor developments won’t be at the show, but will be talked about at the Farrel booth. For the past five years, with no fanfare, Farrel has been using a radial-piston hydraulic motor on single-screw extruders that are gravity-fed hot compound from another extruder or mixer. Farrel also has used this hydraulic motor on mill rolls to form ABS sheet for dicing.

These variable-speed motors are said to be more powerful and compact than a typical crankshaft-type hydraulic motor or an electric motor of the same horsepower. They provide full torque throughout the whole speed range, and they typically mount directly on the drive shaft without gears. Radial-piston hydraulic motors are made by several manufacturers, though Farrel uses motors from Hagglunds Drives.

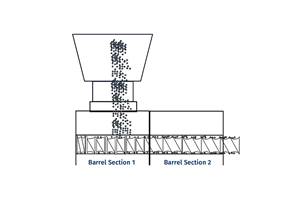

Another development at K is the first commercial application of a new four-motor drive to twin-screw compounding. The CMG drive is built by K. & A. Knoedler GmbH in Ostfildern, Germany, represented here by Henschel America. Henschel’s German parent developed a new drive system, called TMG, that applies the four motors to two screws. The drive is said to increase output significantly over the same size extruder with a conventional drive.

Henschel is building a special counter-rotating twin-screw extruder for the K show with a clear polycarbonate cover to show how the new motor works. Henschel will adapt the drive next to corotating twin-screws.

Although new to production-scale extruders, this motor has been used for a couple of years on a laboratory twin-screw machine by Leistritz in Germany.

Standardized to cut cost

Machine builders will launch new standardized, medium-performance versions of their high-end, customized twin-screw compounders. Berstorff is introducing a new corotating twin-screw, the ZE Basic, which costs about 20% less than its high-end ZE-UTX for nearly the same performance. It offers fewer options and it uses some unusual technology to save cost. For example, an inductive heating method is used to harden the inside of the barrel, reportedly imparting the same wear resistance as bimetallic liners. ZE Basic comes in sizes of 26 to 77 mm with drive packages for maximum speeds of 600, 900, or 1200 rpm.

Berstorff also has a new C-clamp barrel system that allows 70% faster changing of barrel segments than conventional bolted flanges or tie rods.

Coperion will offer a new brand of corotating twin-screws designed in Germany and assembled in China. Called Coperion STS, these models are at least 30% less costly than Coperion Werner & Pfleiderer’s high-end ZSK machines.

STS machines use German-built gear boxes, but the bearings are designed for medium performance and wear. Coperion expects the new Chinese-built line to compete with single-screws rather than the ZSK. The Coperion STS and ZSK machines will be sold in the U.S. by separate sales forces from Ramsey, N.J.

Batch mixing news

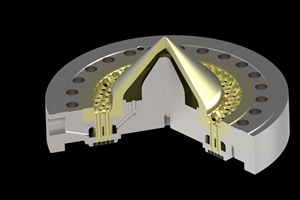

Farrel will introduce a crossover technology from its acquisition of Francis Shaw rubber machinery in 1999. An Intermix intermeshing twin-rotor batch mixer from Shaw has been adapted to mix heat-sensitive plastics. It has five cooling zones instead of two and a modified rotor geometry.

Related Content

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MoreSustainability Among the Many Niches at Niche Polymer

Founded in 1987, Niche Polymer continues to grow—both organically and through acquisition—by focusing its product-development efforts on ever-changing market needs. Adding value to both industrial and post-consumer scrap is a growing part of this effort.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More