K 2010 Preview, Extrusion More…Layers, Output & Quality

In most segments of extrusion technology, the word at K 2010 is more.

In most segments of extrusion technology, the word at K 2010 is more. Perhaps nowhere will this be more evident than in blown film, where at least two machine builders will be running nine-layer lines at the show, while scores of others will have static displays showing new technology aimed at adding more layers to the mix. The same trend prevails in cast film and sheet, while in pipe and profile extrusion the emphasis is on higher throughputs.

BLOWN FILM LAYERS MULTIPLY

Macchi SpA and Reifenhauser-Kiefel will have dueling nine-layer lines at the show. Macchi (macchi.it) will be making structures comprised of barrier layers sandwiched between structural layers of metallocene LLDPE and LDPE. Macchi will be running nine 55-mm, 30:1 extruders driven by Siemens synchronous torque motors. Each will be equipped with barrier screws. The die is the CoexFlex IBC design: a short, compact unit that is said to combine the best features of melt binary splitting and a traditional spiral mandrel.

Reifenhauser-Kiefel (reifenhauser.com) will mark the debut of its Evolution series. The line will consist of nine extruders and incorporate features that promote easier changeovers, better energy efficiency, and higher output.

Hosokawa Alpine (halpine.com) will demonstrate its high-output 5-layer line designed to process a wide range of materials and layer ratios. At the heart of the machine is Alpine’s patented X-Die.On each of the five extruders, the screw is direct-coupled with the drive shaft of a two-stage gearbox and is turned by a water-cooled, asynchronous AC motor. This drive concept is said to be quiet, compact, and low-maintenance.

Brampton Engineering (be-ca.com) will have a static display of its FlexStack SCD (Streamlined Coextrusion Die) die. The die is about half the size of its standard SCD. As a result, it reportedly offers the narrowest residence-time distribution of any barrier blown film die around, which shortens purging times and minimizes scrap generated during resin changeovers.

Macro Engineering & Technology (macroeng.com) will exhibit a 7-layer TaperPack Die, the key component of its DXL-7000 Series of Double-Bubble Lines, used primarily for multilayer shrink bags for meat and cheese.

Also on display will be the latest upgrades to Macro’s D10 Pro air ring, intended to simplify operation. New valves and motors for each control zone improve reliability, and redesigned software provides faster and simpler startups.

Meanwhile, Addex Inc. (addexinc.com) will show a simplified version of its original autoprofile External Gauge Control air ring. The “brains” of the unit have been moved from outside the air ring into the plenum right next to the motors they control. The number of control zones (132 to 244), remains unchanged. The system requires only two motors, one to adjust air flow and another to turn the first one 360°.

The LFR-style air ring to be displayed by Alpha Marathon (alphamarathon.com) uses low-pressure, high-volume air flow and specially designed fins with side intake ports. A fixed lower lip in conjunction with simple and precise adjustment of the upper lip allows for an easy one-time setup.

A new layflat control system from D.R. Joseph Inc. (drjosephinc.com) is intended for non-IBC lines. By measuring the bubble soon after the frostline, the system can achieve proper bubble size without waiting for the film to pass through the top nip rollers. It works even when running gusseted film. This greatly increases the efficiency of the system and reduces the time to get the bubble on size. The LF-Sizer provides the operator with a simple color touchscreen interface that allows entry of the target layflat width.

Davis-Standard LLC, Blown Film Systems (bc-egan.com) will display a new series of surface winders for blown film that employ pneumatics instead of hydraulics to control winding force. The SLC Series can handle roll diameters up to 60 in. It’s available in widths from 44 to 134 in. and can wind rolls on 3- or 6-in. cores.

Brampton will be showing the FlexWin winder, which can wind in center or surface mode or any combination of the two, as well as gap mode. FlexWin can provide center winding with surface assist and offers tapeless transfer with zero fold-over. Its spindles are driven by direct-drive servomotors for precise torque control and energy savings, and a servomotor drives the lay-on roll as well.

HIGH-TECH TOOLING & WINDERS

More sophisticated structures are also in vogue in flat film and sheet. Extrusion Dies Inc. LLC (extrusiondies.com) will be featuring its “layer multiplication” technique, which relies on a special tool that can be engineered to multiply some or all of the layers within a coextrusion “sandwich” provided by a feedblock. The resulting microlayer structure then passes into the die manifold, where it is shaped into a film or sheet of targeted width and thickness. No matter how many microlayers in the structure, the overall thickness is no greater than that of a conventional coextrusion, and the structure contains the same amount of material.

Cloeren Inc. (cloeren.com) will also be displaying “nanolayer” feedblock technology permitting up to 34 layers. This feedblock will eventually be teamed with a Cloeren Epoch III Die and used for nylon, EVOH, TPE, TPU, and PET by an undisclosed U.S. processor. The company will also show feedblocks and dies related to clarified PP and protective and stretch films. A 4000-mm Epoch III AutoGauge 5.5 Die containing an internal deckling system will be paired with a series FG II three-layer TopHat Feedblock. Also at the booth will be a 3600-mm Epoch III AutoGauge 5.5 Die with a series FG III five-layer feedblock for stretch film. Both systems are already running in Asia.

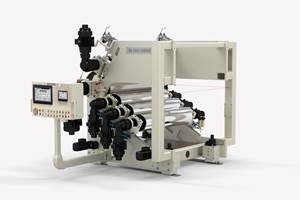

In sheet, Processing Technology Inc. (ptiextruders.com) will show the latest member of its Revolution series of roll stacks. The Revolution H-Stack is a horizontal configuration particularly suited to materials with low melt strength: The material can be accurately placed between the cooling rolls, ensuring that it is “nipped” on both sides at precisely the same moment. Each roll is direct-driven individually and configured with linear-bearing-guided roll actuation, providing the precision and repeatability required to process thinner, high-quality sheet.

Dolci Extrusion srl (dolciextrtusion.it) will be displaying a 1-meter-wide stretch-film line. The FCL 3/1000 can operate at speeds to 1800 lb/hr. Dolci will also show a shaftless winder for machine rolls and hand rolls on a 1.5-meter cast film line. It can provide line speeds of of 800 meters/min and a changeover cycle of 17 sec.

MORE POTENT PIPE, PROFILE MACHINES

Battenfeld Cincinnati (represented in the U.S. by American Maplan, maplan.com), will be showing a new series of parallel twin-screw extruders for PVC profiles. Four machines with screw diameters from 78 to 135 mm and a 34:1 LD provide outputs from 220 to 2200 lb/hr, 25% higher than previous models.

KraussMaffei Berstorff (kraussmaffei.com), will be showcasing technology for producing pipe up to 95-in. diam. A series of single-screw extruders in 105, 125, and 150 mm diam. all have 36:1 LD. The extruder features a barrier screw for low and uniform melt temperature. In the pipe head, specially engineered for extra-large diameters, the melt is gently predistributed via multiple holes to produce an ideal circular cross section before it reaches the spiral channels. The die set can be manually pre-adjusted. A number of heating-oil circuits and segmented heater bands support accurate wall-thickness control. The new head reportedly also results in pipe with much improved inner surface.

KM-Berstorff will also show its QuickSwitch extrusion system, which makes it possible to change polyolefin pipe diameter and wall thickness within minutes on the fly. At the touch of a button, the complete extrusion line changes automatically to the new dimensions, reducing the waste normally produced during changeovers. Because it’s a modification of the previous design—the die is adjustable, while the pin is fixed—the die can be retrofitted to conventional standard pipe heads.

Amut spa (amut.it) will show the BA 114 Cemax parallel counter-rotating twin-screw extruder. Aimed at processing window profiles at more than 1300 lb/hr, it has a 30:1 LD to also enable processors to run rigid PVC pressure pipe at 2400 lb/hr. The extruder will be exhibited with a head for PVC pipe up to 630-mm diam.

In extrusion auxiliaries, a new screen changer from Maag (maag.ch), model CSC/BF-PE, offers fully automatic screen cleaning that can be adjusted for any kind of process. The quantity of melt needed for backflushing is collected in a permanently flushed accumulating space, and will then clean the dirty screen cloth outside the production process by backflushing.

Dynisco (dynisco.com) will be showing the Opt•Trol System, described as an affordable, expandable, integrated extrusion control system. It combines adaptive, autotuned temperature, pressure, and speed control as well as differential control and process-variable trending from a user-friendly color touchscreen. The system can be used on new extruders or retrofitted to existing equipment.

Dynisco is also displaying The SPX-T, a smart 4-20 mA pressure transmitter that includes Temperature Compensation, a feature that reduces drift due to changes in ambient temperature by as much as 80%.

Related Content

Crosshead Die Features Single-Point Concentricity Adjustment

One adjustment bolt controls 360° of adjustment.

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreTeel Straps on Yellow Belt to Cut Scrap on Big Cores

Investments in a lean, continuous process pay off for this Wisconsin processor.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)