K 2022 Preview: Engineering Materials for Sustainability and E-Mobility

Materials that are sustainable yet offer equal performance to their fossil-based counterparts will be prominent at K 2022.

New Tepex composites based on recycled or biobased raw materials including one made with flax fibers and PLA and one with a nylon 6 matrix made from “green” cyclohexane and well over 80% sustainable materials are being launched by Lanxess. (Photo: Lanxess High Performance Materials)

Here is a brief preview of the type of new material technologies you can expect to see showcased at K 2022. Based on advance word from five key suppliers of materials and additives, this offers a glimpse of what is being developed to meet sustainability goals across the supply chain and particularly in the growing e-mobility sector. Lots more news covering a broad range of industry sectors will be forthcoming in our September K 2022 Preview.

Sustainable High-Performance Styrenics & Nylons

Ineos Styrolytion has developed Luran S Eco B with up to 50% renewable (bio-attributed) content, said to be the first biobased ASA (acrylonitrile styrene acrylate) resin on the market. It is based on the company’s Luran S ASA, used in the construction industry and auto exterior parts, as well as toys and sports/leisure applications. The Eco B version is produced using renewable feedstock such as household kitchen and/or wood waste. LCA analysis reportedly shows that Luran S Eco B products will offer up to 58% lower carbon footprint compared with the respective fossil-based products.

Also new from Ineos Styrolution will be four grades of mechanically recycled Novadur Eco and Novadur Eco HH ABS resins for household appliances and automotive, respectively. Up to 100% PCR content is possible, depending on the application, and color options (e.g., red and blue) will be available in addition to black and white.

As a fully integrated producer of durable materials, Ascend Performance Materials claims a unique ability to tailor nylon resin chemistry and global compounding expertise to help achieve sustainability goals. The company’s recent acquisition of Italy’s Poliblend, a manufacturer of high-performance compounds from PCR, has led Ascend to redefine its material portfolio to have a combination of PIR and PCR content. Ascend also will begin making and using biobased feedstocks for nylons. By 2023, the company will offer biobased acrylonitrile, hexamethylene diamine and nylons based on them. At K 2022, the company will launch half a dozen glass-filled nylon compounds with 20% to 40% biocontent:

▪ Vydyne Thermaplus is a new technology platform of high-temperature, high-ductile nylon 66 for clips and fasteners. It’s designed as a replacement for DSM’s Stanyl nylon 46. The new Ascend materials boast better thermal stability, and they have won commercial applications in e-mobility where they are used in fasteners

▪ Full portfolio of UL “yellow-card” certified Starflam FR nylons for a variety of performance requirements. The company’s recent acquisition of France’s Eurostar Engineering Plastics, a manufacture of flame retardants, is key for Ascend’s plans to be a major player in e-mobility and electrical components.

▪ HiDura is a growing portfolio of long-chain nylons 610 and 612 for injection molded consumer goods and connectors, as well as copolymers for films that make packaging more durable. Grades are being introduced with 40% to 60% biobased content.

▪ Ascend e-mobility application-development engineers and polymer scientists have created what is said to be a novel solution to dampen NVH in electric vehicles. EV motors produce vibrations at 10 times the frequency of internal combustion engines, making standard automotive under-hood dampening materials less effective. Vydyne AVS nylon 66 is a new engineered material that is reportedly effective at dampening high-frequency vibrations at the motor, which translates into an 80% reduction in cabin sound pressure.

Meanwhile, DSM Engineering Materials has developed what is said to be the first 100% biobased high-temperature nylon—in this case a more sustainable version of its flagship Stanyl product. New Stanyl B-MB (Biobased Mass Balanced), with up to 100% biobased content from biomass-waste feedstock, enables DSM to halve the carbon footprint of this product line.

Ineos Styrolution’s new Luran S Eco B has up to 50% renewable content and will offer up to 85% carbon footprint reduction compared to fossil-based Luran S. (Photo: Ineos Styrolution)

Other New Sustainable Engineering Resins

Lanxess’s High Performance Materials business unit is also focused on sustainable material and lightweight solutions. Main areas are materials and component concepts for lightweight construction in the developing market of e-mobility—for example, lightweight structural components based on Tepex-brand continuous-fiber composites in the field of batteries for passenger cars.

Lanxess will present new Tepex composites based on recycled or biobased raw materials. One example is brand-new Tepex dynalite Scopeblue 813, which is produced from flax fibers and PLA biopolymer. Also at hand will be a Tepex dynalite with a nylon 6 matrix that is produced from “green” cyclohexane and utilizes well over 80% sustainable raw materials.

Another focus is on tailored solutions for electric vehicles’ powertrains or charging infrastructure. Here, plastic components are often exposed to higher temperatures and at the same time very strong electrical currents and voltages. Plastic connectors, for example, must remain electrically insulating under these conditions and must not allow “creepage” current to occur. Lanxess is launching a new halogen-free flame-retardant and hydrolysis-stabilized PBT compound for these high-voltage connectors.

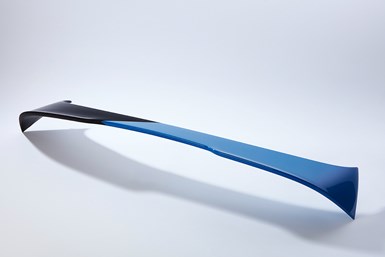

SABIC will emphasize two key areas at K 2022: the circular economy for plastics and a clean-air economy through the transition to product electrification. With road transport making up a significant share of total global CO2 emissions, SABIC’s new BlueHero program will build upon the company’s established materials and capabilities to help the automotive value chain move ever closer to a world with zero tailpipe emissions, with an emphasis on improving structural battery components with unique flame-retardant materials and solution development expertise. Material examples include Stamax FR LGF-PP and SABIC FR PP compounds. The latter is used on Honda’s Edison Award winning battery cover. Other materials, also offered in FR grades, inclide Lexan PC, Cycoloy PC/ABS, and Valox PBT. The company expects to strengthen and expand its thermoplastic offering to help enable electrification with the elevated focus and new investments that will become available under Bluehero.

SABIC’s new Bluehero program is designed to help accelerate the world’s energy transition from fossil fuels to electric power with a special focus on improving structural EV battery components with unique flame-retardant materials. (Photo: SABIC)

SABIC also will highlight its Trucircle program for accelerating the transition of the plastics industry to a circular economy. New certified bio-renewable-based SABIC PP compounds are targeted at high-performance automotive applications, from bumpers and painted or unpainted exterior trim to interior door panels, instrument panels and visible interior trim. Certified bio-renewable based long-glass PP Stamax compounds are targeted at structural automotive applications such as front-end carriers, instrument-panel carriers, tailgate structures, door modules and others. The new SABIC PP compounds and Stamax resins reportedly can replace corresponding SABIC fossil-based grades with no need of lengthy technical validation, as they offer the exact same level of performance and quality.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreWhat is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

Read MorePrices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

Read MoreTracing the History of Polymeric Materials: Acetal

The road from discovery in the lab to commercial viability can be long, and this was certainly the case for acetal polymers.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)