LLDPEs Combine Stiffness, Toughness & Easy Processing

ExxonMobil’s new Exceed S series can reduce the complexity of film structures and formulations while boosting processability and film performance.

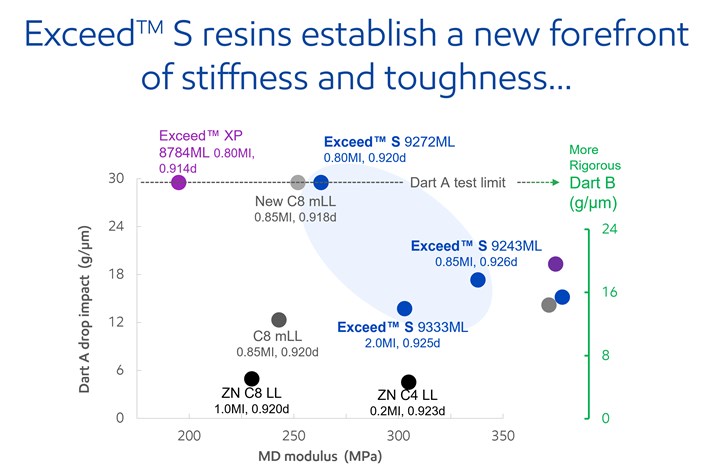

A new series of hexene-based LLDPE film resins recently unveiled by ExxonMobil boasts “industry-leading combinations of stiffness and toughness” while being easy to process. Produced with a proprietary metallocene catalyst, Exceed S performance LLDPEs provide opportunities to reduce the complexity of film formulations and structures while improving processing, converting, film performance and package durability.

Targeted for use in food, industrial and agricultural applications, Exceed S resins can enhance mono-material design for recycle and help enable recycle-containing solutions while unlocking film and package production efficiencies, according to Tom Miller, marketing manager.

Used in the core and skins, Exceed S resins can produce more rugged heavy-duty sack films compared to market reference films. Photos: ExxonMobil

Miller and his team say that optimizing the balance of stiffness, toughness, and ease of processing is the leading challenge in producing high-performance flexible films for packaging, agricultural and industrial applications. They describe a typical example: “A film designer looking to improve the relatively low toughness of a generic, cost-effective coextruded structure will likely upgrade to mLLDPE. To then make processing easier, LDPE is often added to lower melt pressure and increase melt strength, which can lead to higher output. HDPE is then often added to make the film stiffer, but this can reduce toughness. So, adding either LDPE or HDPE introduces compromise and increases operational complexity.”

Miller confirms that the company is currently working with over 75 film processors globally in more than 100 applications using Exceed S resins, which have been shown to exhibit the “highest toughness at every level of stiffness.” He says innovative processors can rethink film design by:

▪ Utilizing Exceed S functional layers to maximize performance;

▪ Leveraging increased performance to help facilitate solutions with sustainability benefits;

▪ Reducing the need to add HDPE for stiffness or LDPE for easy processing;

▪ Creating flatter, less extensible films to increase print and package line efficiency;

▪ Delivering more durable flexible packaging to help reduce food waste.

Uses in Core, Skin and Combination Film Designs

The Exceed S series currently comprises three grades:

▪ Exceed S 9333ML, a 0.925 density, 2.0 MI resin designed for a combination of high stiffness, high toughness, and exceptionally easy extrusion in a range of blown and cast applications.

▪ Exceed S 9272ML (0.920 density, 0.80 MI), which has a combination of high dart impact and stiffness that is greater than the density suggests and thus can help increase the durability of coextruded packaging.

▪ Exceed S 9243ML (0.926 density, 0.85 MI), which boasts a combination of high dart impact and high stiffness, which makes it the grade best suited for stiff and tough functional layers that can help improve package durability.

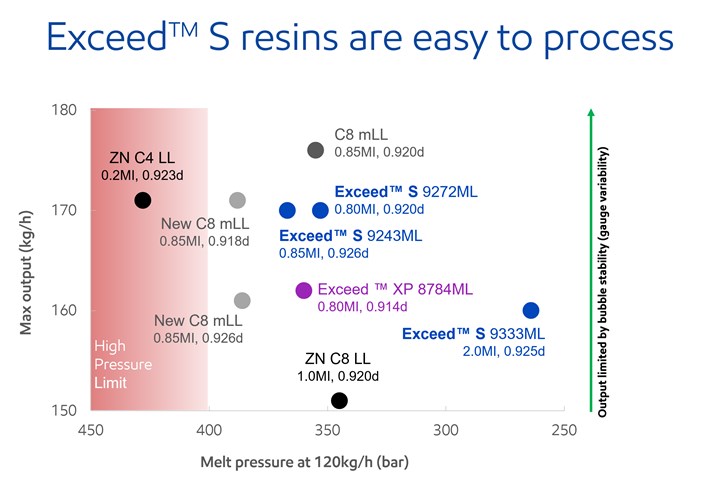

Due to their outstanding stiffness and toughness, along with better melt strength and higher output than current mLLDPE resins, Exceed S resins allow film designers and engineers to rethink film design for simpler solutions. Miller reports that LDPE and HDPE can either be eliminated or amounts reduced, depending on the needs of the application.

Using Exceed S PE resins in the core of a film formulation creates a single functional layer that delivers the stiff/tough backbone needed by the application. The stiffness and toughness are so high that up to 20% HDPE can be removed from the formulation, depending on the resins used in the blend. The low melt temperature and low melt pressure offered by Exceed S resins make them easy to process, eliminating or reducing the need for LDPE and providing film producers with opportunities for higher output and cost savings.

With the core layer delivering high stiffness and toughness, the skin layers of the film are available to enhance other aspects of performance like sealing, hermeticity, optics or haptics that brand owners value in the final package. Exceed S resins thereby simplify blend formulation while creating opportunities to better optimize film and finished package durability and consumer appeal.

According to Miller, Exceed S PE resins can create the most value when used in the core of three-layer coextruded structures or the core and sub-skins of coextruded structures with high layer counts. There are a few applications, however, where moving the stiffness/toughness functional layer to the skin creates more value. These are applications with critical performance attributes like:

▪ Resisting blocking and improving heat resistance of hot-filled bag-in-box;

▪ High amounts of HDPE in the core of heavy-duty sacks for creep resistance;

▪ Incorporating recycled content in the core to improve sustainability.

The low melt temperature and low melt pressure offered by Exceed S PE resins make them easy to process and provide opportunities for high output, helping film producers realize cost savings and increase revenue. Also, many lean blends of HDPE in LLDPE can be replaced with a single grade of Exceed S. Simplified formulations, easier operations, and the potential for fewer coextruded layers can all contribute to reduced complexity and fewer opportunities for operator mistakes and equipment malfunctions that generate scrap and increase costs.

Used in air bag (tube) applications, Exceed S film resins can enhance toughness and durability, compared to market reference films to protect fragile contents.

The inherently high stiffness of Exceed S resins can deliver stiffer, less elastic, and less extensible films that should run more efficiently on high-speed gravure printing lines. These same characteristics can also help ensure more accurate indexing and less problematic web-tension control on packaging lines, which can lead to lower scrap costs and improved quality.

Inherently high dart impact, puncture, and flex-crack resistance all contribute to improved film performance. Along with the ability to create stiff, tough core layers, this can enable use of lower-density or other higher-performance skins that further improve bag-drop survivability, enable faster sealing, improve clarity and gloss, or enhance package feel. The result can be more durable PE packaging that can be recycled mechanically or by advanced recycling. This packaging can also better resist breaking or leaking during transportation or use by the consumer. In e-commerce, for example, this can mean fewer product complaints and returns, which can help reduce the cost associated with refunds or supplying replacement products.

Applications that ‘Shine’

Exceed S resins demonstrate significant value in such applications as:

▪ Non-laminated pillow pouches (liquid filled), where Exceed S in the core layer can deliver comprehensive improvements in package performance compared with a market-reference film. Package toughness and durability can be maximized. HDPE can be eliminated or reduced while high stiffness and toughness are maintained. Melt temperature and pressure can be reduced, which may help improve output. Lower-density sealants can be used in the skins to speed heat sealing.

▪ Laminated PE/PE pillow pouches (liquid and solid filled), where Exceed S in the sealant web enhances toughness and durability compared with a market -eference film. A single-resin core paired with low-density skins maintains laminate stiffness, enhances dart impact and facilitates fast sealing. Outstanding bag-drop performance increases the chances of package survivability, potentially enabling the use of larger packages, and promoting the use of full-PE packaging for more aggressive contents.

▪ In two different classes of heavy-duty bags for non-resin applications, Exceed S in the core and skins produces a more rugged film vs. market-reference films. In 25-kg industrial and agricultural bags, high dart impact, MD tear and stiffness are provided as required for bagged products like potting soil sold directly off of pallets at DIY stores. There is also a combination of excellent tear and stiffness with less blending and less HDPE added. In up to 50-kg industrial and agricultural fertilizer-type bags, premium dart and tear is provided, as required for rough handling in the field, with significantly less HDPE added.

▪ In agricultural silo bags, Exceed S can deliver elevated performance compared with a market-reference film. Used in the core and skins, these resins enhance MD tear, TD creep resistance, dart impact, and needle puncture performance in a film that is 6% thinner. Using Exceed S in the core and Exceed XP LLDPE resins in the skins offers near-comparable improvements in performance, a 13% thinner film, and potentially higher output.

▪ In hot-filled bag-in-box liquid packaging, Exceed S in the skin layers can deliver comprehensive improvements in packaging performance vs. a market-reference film. These resins have been shown to deliver premium, next-level flex-crack resistance. They also reduce blocking by providing a higher seal-initiation temperature (SIT). There is also potential for an increase in hot-liquid packaging line speeds due to more heat-resistant bags.

Exceed S resins boast “industry leading combinations of stiffness and toughness” while being easy to process. (Image: ExxonMobil)

Related Content

Wisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreVariable-Diameter Air Ring Cools Film Above Frost Line

Tower-mounted adjustable ring adds cooling so that blown film can run at optimum line speeds with structures having soft inner skin layers that tend to block.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreRead Next

ExxonMobil Linear Alpha Olefins Production Unit On Course for Commercial Startup in Mid-2023

A fully range of LAOs will be produced and sold under the Elevexx brand.

Read MoreExxonMobil Completes First Commercial Sale of Certified Circular Polymers

Berry Global is the company’s first customer of resins based on ExxonMobil’s Exxtend advanced recycling of plastic waste technology.

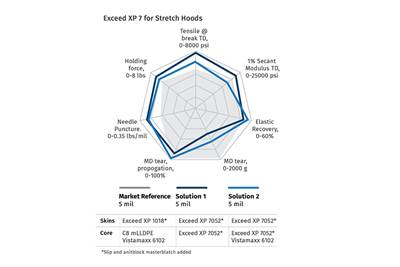

Read MoreNovel LLDPEs Enable Films that Are 'Ahead of Their Time'

ExxonMobil’s new Exceed XP 7 series boasts remarkable mechanical performance combined with low density and fractional melt index.

Read More