Low-Scrap Thermoforming Competes In Medical Orthotics Manufacturing

An example of how thermoforming is expanding into more and more sophisticated and high-tech applications is the case of orthopedic devices to improve posture, function, and mobility.

An example of how thermoforming is expanding into more and more sophisticated and high-tech applications is the case of orthopedic devices to improve posture, function, and mobility. Restorative Care of America Inc. (RCAI) in St. Petersburg, Fla., relies on innovative use of thermoforming to produce orthotic devices. It claims to be unique in its use of this process, while competing products are based on metal or injection molded plastics.

RCAI has expanded its use of vacuum forming and a variant of the process called drape forming to produce splints, cuffs, stays, hinges, braces, and joints that comprise many of its roughly 70 orthotic products. RCAI is enjoying annual growth of up to 10%. Its most popular device is the foot orthosis, which comes in nine sizes.

Drape forming’s benefits

Orthotics traditionally have relied heavily on aluminum and stainless steel. But conventional orthotics exert pressure on sensitive body areas that can contribute to soreness, and they can be difficult or impossible to adapt to individual patients by a doctor. RCAI says its use of plastics overcomes both those limitations. Most of RCAI’s products use drape-formed Kydex high-impact acrylic/PVC sheet from Kleerdex Co. LLC, Bloomsburg, Pa. It offers flexibility, tensile strength, and toughness.

In the drape-forming process, a 4 × 4 ft sheet, 0.125 to 0.187 in. thick, is heated to around 295 F, well below the material’s melting point of 320 to 390 F. Semi-molten sheet is then machine-stamped into a template of various parts arranged to minimize scrap (typically only 3%). The templates are cut into individual parts with a CNC router, Those parts are reheated to around 295 F, and loaded into a cold mold half (typically made of a composite). The soft sheet conforms to the mold without any pressure or vacuum. Cycle time is around 2 min.

Compared with traditional thermoforming, drape forming is relatively simple, “low-tech,” and more labor intensive. It yields parts with minimal built-in stress, exceptionally low and predictable shrinkage, and highly uniform wall thickness.

According to RCAI, drape forming offers new design opportunities. The approach makes it feasible to eliminate pressure points and reduce the risk of contact soreness. Drape molding also permits the orthotic device to be reheated and reshaped in the field with a heat gun by medical practitioners. Orthotics can thus be repositioned at a new angle, or a range of motion can be modified as prescribed by a doctor’s treatment plan.

Heat-formability of drape-formed parts also means that orthotics supplied in basic prefabricated sizes can be custom-fitted to individual limb sizes or conditions (e.g., degree of swelling). For example, the diameter of a holding cuff can be modified for precise fit on an affected limb. RCAI says Kydex sheet allows parts to be adjusted many times without compromising tensile strength or other key properties.

RCAI has also extended its capabilities to include vacuum forming of orthotic parts that require high draw ratios, more variable wall thickness, or properties offered by alternative thermoplastics. For example, RCAI vacuum forms polyethylene into universal wrist/thumb splints and shoe inserts; and nylon is used for hinges, support plates, and ball-and-socket joints.

RCAI drape forms about 12,000 parts monthly and vacuum forms a similar number. It faces strong competition from China and Costa Rica. Cost pressures in recent years have forced many orthotics suppliers to make their parts offshore, but RCAI’s “made-in-the-U.S.” approach has succeeded despite its labor-intensive nature, says Bud Hess, RCAI president. He credits in part the low scrap and minimal reject rates for drape forming and vacuum forming, plus the ability of these technologies to meet just-in-time deliveries. Turnaround time for custom plastic parts is three to four weeks, versus 10 weeks for competitors who rely on foreign-made parts.

Related Content

OMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

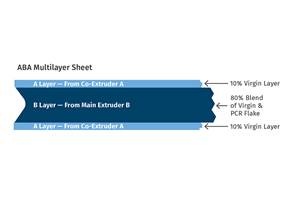

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More