LSR Molders Now Can Tailor Cure Speed, Temperature & Durometer

Elkem’s LSR Select is enabling faster cures at lower temperatures and custom durometer blends. Dosing equipment has caught up with capabilities of this novel material system.

After five years in development, a radically different approach to LSR processing has made its commercial debut. Called LSR Select, the technology allows injection molders a new freedom to adjust the cure time and temperature, as well as the durometer, of their LSR formulation, no longer limited to the choices among standard two-part systems on the market. In many cases, faster cures and/or lower cure temperatures are possible, as well as fine-tuned durometers different from those offered in standard LSR systems.

LSR Select was introduced publicly at the Molding 2014 Conference in January 2014 in San Diego (see March ’14 Blog). It achieved limited commercial use while it underwent further development until its commercial launch in 2018. LSR Select was originally developed in the U.S. by Rhodia Silicones, which later became Bluestar Silicones, a Chinese-owned company. The technology is now under the wing of Elkem Silicones, div. of a Norwegian company (Elkem ASA), purchased by China National Bluestar in 2011. All the Chinese parent’s silicones activities are now under Elkem Silicones.

NOVEL ONE-PART LSR SYSTEM

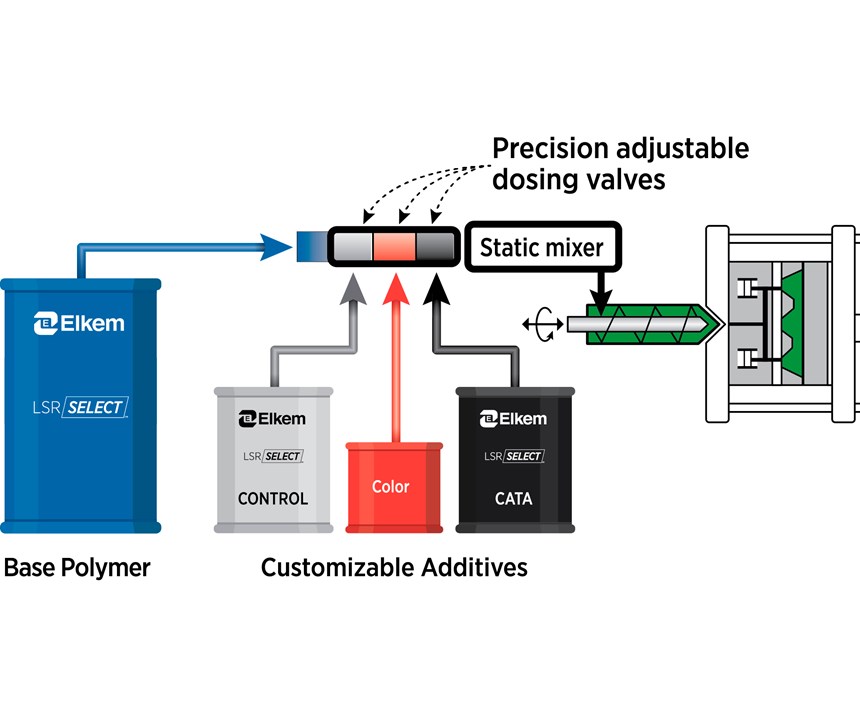

The first thing that distinguishes LSR Select from standard two-part (“A” and “B” sides) is that it has only one base-resin component and two curing-agent additives, and potentially other additives to achieve specific properties. A typical two-pot LSR system has one base resin component with catalyst mixed in and a second base-resin component with inhibitor blended in. The two are typically blended 1:1 by the pumping/dosing unit. The curing behavior is built into the system, though it can be varied to some extent by adjusting temperatures of the mold and/or injection-machine barrel.

According to Chris York, president of Elkem Silicones Americas, E. Brunswick, N.J., “We took apart the two-component LSR system and put it back together as three components.” An LSR Select formulation consists of one resin component plus a catalyst masterbatch additive (“LSR Select Cata”) and a cure-control agent (“LSR Control”), which serves the function of the inhibitor in the two-part package. The platinum catalyst masterbatch is added at a fixed percentage—typically 1%, while the amount of control/inhibitor additive can be varied over a range of 0-6%, according to the cure speed desired. Adding more of this agent delays the gel and overall cure, and vice versa.

Separating these components and allowing the molder more control of the cure profile “sets the chemistry free to do things it has been ready to do for many years,” says York. For example, a lesser amount of the control/inhibitor additive can help speed curing of smaller parts, while a larger addition of control/inhibitor could ensure complete filling of larger parts without pregel but achieve faster overall cure than would otherwise be possible. Elkem claims—“very conservatively,” according to York—that molding productivity can be improved by 20% to 60%, though improvements of up to 125% been verified in some trials.

Although speed was the first goal in developing LSR Select, York says that two other benefits have emerged more recently. One is the ability to mold at lower temperatures, which can save energy and permit overmolding LSR onto lower-temperature thermoplastics like PP. For example, LSR Select has been molded at temperatures down to 75-80 C or lower, vs. a more typical 165-170 C or higher, with little or no sacrifice in cure speed. For example, a part molded with a 50-sec cure at 165-170 C can now be molded in 50 sec at 100 C.

A second newly realized benefit is the ability to blend base resins to tailor final product durometer. Two different LSR Select base resins can be placed in the same two-part pumping system to achieve intermediate Shore durometers, even more so if the metering system is capable of adjustable A-B ratios.

Elkem’s LSR Select base resins are currently available in four hardnesses from 20 to 70 Shore A, and in Silbione LSR Select medical grades over the same range. York claims that LSR Select materials are more consistent within the same batch, so that the usual durometer variability of ±3-5 Shore A units now can be held to ±1-2 units. Part of that improvement is also due to the advent of more precise metering machines.

Elkem notes that as the technology continues to evolve, Elkem anticipates coming out with specialty additives for antimicrobial, self-bleeding, self-bonding, and other properties. These additives will be used with standard base resins, eliminating today’s need to buy specialized A-B formulations to achieve these properties.

SPECIAL EQUIPMENT NEEDED

The number-one factor in the long gestation of LSR Select technology, according to York, is that “the equipment finally caught up with the materials technology.” The key factor was developing the ability to meter precisely and repeatably to two cure additives. Although Rhodia (now Elkem) began by working with Graco to develop a special metering system, this was never an off-the-shelf product and only a few were built.

The breakthrough, says York, was the arrival in 2016 of the high-precision TOP 5000 P metering/pumping system from Elmet of Austria. “It’s a game-changer,” states York. Its extremely stable pumping of the base resin for precise durometer blends, and additive metering accuracy of ±0.1%, plus various software improvements, are said to provide reliability and traceability. Software adaptations also provide for variable A-B ratios in order to tailor durometer blends. Elkem is working with several other equipment suppliers to provide systems suitable for LSR Select.

Elkem says it has a handful of commercial users for LSR Select in healthcare and industrial applications, and several more in trials or “on the verge” of commercialization.

Related Content

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreSilicone Elastomer Course Returns

After completely filling the classroom last year, the Silicone Elastomers Technology and Fabrication course returns to Pomona, Calif. Jan. 31-Feb. 3.

Read MoreNew LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)