Materials: Cycle Time—Science vs. Rules of Thumb, Part 6

This installment—on elastomers—completes a series, whose theme is to bring more science to the discipline of molding. The overall message: Ask a lot of questions whenever someone posits this or that ‘rule of thumb’ about processing.

We have been reviewing the principles that govern the estimation of cycle time, one of the most important aspects of determining part cost and profitability for the processor. We have shown that modulus development as the material cools is the primary consideration in determining cycle time, and we have profiled the behavior of various types of rigid and semi-rigid polymers.

The last classification that we need to treat is elastomers. To be used as an elastomer, a material must remain above its glass-transition temperature (Tg). In addition, elastomers cannot lose all of their load-bearing properties above their Tg, as traditional amorphous polymers do.

Want to learn more about materials? Visit the Materials Zone.

But they also must establish a significantly lower modulus than a semi-crystalline rigid polymer does when it is above its Tg. Most elastomers have a modulus of 1-50 MPa (145-7250 psi) at room temperature unless they are on the high end of the hardness scale, where the hard block is contributed by a crystalline structure, as in a polyester elastomer or a thermoplastic polyurethane. In these cases, the room-temperature modulus will be somewhat higher, in the neighborhood of 100-500 MPa (15-75 kpsi). But in almost all cases, the modulus will be low enough that if the heat-deflection temperature were to be measured it would give a value below room temperature. This is why you rarely see HDT (or DTUL) provided on a data sheet for elastomers and even for some flexible thermoplastics such as polyethylene.

Cycle time depends upon a host of factors, and pretending that is as simple as achieving the HDT or some percentage of the HDT is not supported by the science or by our experience.

This means that if we apply the rule that the HDT is somehow a critical factor in estimating cycle time, we would need to run very cold molds in order to achieve an ejectable condition. Clearly, we do not do this. Many molds run elastomeric materials at temperatures above ambient, sometimes significantly above it. Liquid silicone rubber (LSR), a very soft material with a room-temperature modulus in the range of 5-15 MPa (725-2175 psi), is run in very hot molds in order to ensure proper crosslinking.

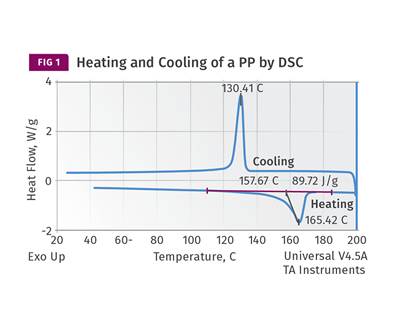

Yet the parts come out of the mold in a reasonable amount of time without achieving cryogenic conditions. Figure 1 shows a plot of elastic modulus as a function of temperature for four different grades of TPU with different surface hardnesses.

It is easy to see that the materials exhibit a relatively low modulus at room temperature. They have to in order to function as elastomers. If they were to cool below the Tg, in the range of -15 to -25 C (5 to -13 F) they would behave like hard, rigid materials. Typical mold temperatures for processing TPU are 25-60 C (77-140 F). This should not work if the HDT is a barometer of cycle time.

Figure 2 shows the behavior of modulus with temperature for a silicone. The glass-transition temperature of most silicones is below -100 C (-148 F). These plots show that a significant level of stiffness does not even begin to develop until the temperature drops to approximately -40 C/F. But molds producing silicone parts run very hot and the parts still come out of the tool. If the rule relating HDT to the ability to eject the part were true, processors would be running liquid nitrogen through their molds.

No one is saying that this is easy. Demolding an elastomeric part requires special attention to detail in the areas of ejector support and surface finish. Sometimes coatings are applied to the mold surface to aid in release, and additives are employed in the materials themselves to aid in this process. But this is exactly the point: Cycle time depends upon a host of factors, and pretending that is as simple as achieving the HDT or some percentage of the HDT is not supported by the science or by our experience.

Einstein once said that things should be made as simple as possible, but no simpler. Rules of thumb like the one we have been discussing are a good example of trying to oversimplify a very complex problem. They tend to discourage the serious inquiry needed to establish true understanding of the problem and the principles that truly govern the behavior of the materials that we work with.

There is a deeper issue here. Plastic processing has suffered from a significant degree of commoditization (yes, it’s a word). The general perception on the part of the procurement people who purchase plastic parts is that it is a simple process and that anyone with a couple of machines and a little floor space can “squirt plastic.” In reality, the injection molding process involves applying immense amounts of pressure to force a pseudoplastic, non-Newtonian fluid into a closed system at very high temperatures and velocities.

This part of the process alone is incredibly complex. Just ask the people who have been refining our simulation software for the last 40 years. The polymer then enters a mold running hundreds of degrees cooler, and the ensuing process of developing a frozen layer while continuing to apply the appropriate pressure to the rapidly cooling material has a significant influence on how the properties develop in the molded part. The argument can be made that plastic injection molding is one of the most complex manufacturing processes in existence.

The general perception of the procurement people is that molding is a simple process and that anyone with a couple of machines and a little floor space can “squirt plastic.”

When we minimize the significance of the endeavor, we not only do a great disservice to those who do the work every day. We also take the focus off of the importance of establishing an optimal process and the skill it takes to do so. This kind of cavalier approach virtually guarantees that buyers will continue to purchase solely on price and search for the cheapest labor markets they can find, regardless of how far they have to go to find them.

The resulting downward pressure on price erodes profitability and discourages much-needed investment in innovation within the manufacturing facilities, where new ideas can be trialed in a practical setting. In a race to the bottom, there are no winners.

So the next time you hear someone pontificating about this or that “rule of thumb,” ask a lot of questions. Peel back the layers until some real understanding emerges. It will be worth the effort and it will bring a greater level of science to the discipline of molding plastic parts.

ABOUT THE AUTHOR: Mike Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe, LLC, is based in Sedona, Ariz. He has more than 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

Custom 3D Printed Parts Made From Bio-based Elastomers

Erpro's custom part printing service will now offer Arkema's Pebax RNew elastomer.

Read MoreTPE Made with 50% PCR Derived from End-of-Life Tires

Prism Worldwide has commercialized its first TPE with this type of recycled content based on its patented technology.

Read MoreAdvanced Plastomers for Production of PE-Based Sealant Resins

Nova Chemicals’ new Astute products are suitable for a broad range of applications including food packaging, heavy-duty sacks and e-commerce.

Read MoreBiobased TPU for Broad Range of Applications

BASF’s Elastollan N contains 50% renewable raw material.

Read MoreRead Next

Materials: Cycle Time: Science vs. Rules of Thumb—Part 5

Let’s examine the behavior of semi-crystalline materials that never reach their glass-transition temperature as they cool.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More.jpg;width=70;height=70;mode=crop)