MATERIALS: The Problems with Single-Point Data

It’s time for material suppliers to take a fresh approach to providing data. Thankfully, things are starting to move in that direction. Part 12 of 12.

The fact that this is Part 12 of the discussion of single-point data means that we have been dealing with this topic for a year, and we could spend a lot more time on it. There are thousands of ways to illustrate the shortcomings of the way we view the performance of polymers and many examples of the negative consequences of such a treatment. But at some point we need to move on to other subjects. I am confident that the industry will evolve and there are positive signs that this is happening. It is worthwhile, however, to look back over what we have covered and summarize some key points.

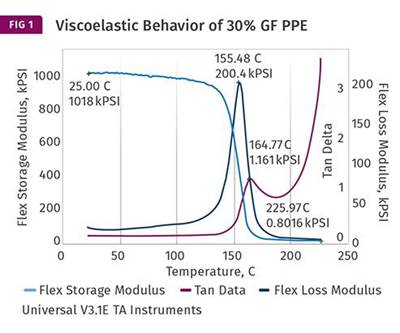

First, all of the values that appear on the data sheets are points on a curve that are selected either because they are easily identified, such as the yield strength of a material, or because they are the output of a particular test regimen defined at some point in the past when the associated method was developed, such as the heat-deflection temperature of a material. In order to truly understand the behavior of a material, it is important to have the curve. Thirty years ago it could be argued that this is too difficult to provide, the graphics require too much programming or too much memory. Today it is simple to communicate these curves in great detail through the magic of a spreadsheet that can then be plotted, studied, and manipulated to capture whatever the user needs to know.

Second, not all databases are created equal, and some suppliers are more forthcoming than others with the expanded data sets we have been discussing. Some third-party databases are nothing more than a collection point for the data sheets we have been discussing. They may make it easier to search for these documents by putting them all in one location. But what value does this provide? Other databases include multi-point data that can be searched and even downloaded for future use. The availability of the multi-point data varies significantly from material to material and supplier to supplier. Generally, it is more available for the higher-performing materials simply because it is more critical to know the full performance spectrum of materials used in demanding environments than it is when a material is a so-called commodity.

While searching the resources of specific material suppliers may take more time, it is often the case than an even more complete set of properties can be found in the design guides provided by these companies. In addition, there have been efforts to create databases over the last 25 years that did not succeed in pulling together the big picture but did generate a lot of excellent results. These have been put out in the public domain and can be found with a little searching.

However, unlike the multi-point data provided by the third-party databases, these graphs are just that, images where actual data points need to be estimated visually or through manual scaling. Here again, the providers of high-performance materials will tend to provide a detailed set of graphs for a broad set of grades. Even if the properties of a specific grade are not addressed, they may be interpolated if closely related materials have been characterized. For example, if a supplier has available data on a 15% and a 45% glass fiber-reinforced nylon, it can be a relatively simple matter to estimate the properties for a 30% or a 35% reinforced material.

In all cases, play close attention to the units and the presentation in the graphs. We still live in a world where the metric system and the inch-pound system exist alongside one another, and the ability to convert is still important. In addition, as we pointed out in the last article, much of the data is presented in a logarithmic format and it is easy to miss the significance of a graph if this is not recognized.

Providers of commodity resins such as polyethylene and polystyrene are unlikely to supply anything beyond the numbers on the data sheet. This does not mean that advanced characterizations are not needed for materials in these families. Some years ago, I worked on a problem concerning HDPE that was in constant contact with gasoline. It was recognized that the strength and modulus of the material were declining as the amount of absorbed gasoline increased. In addition, there was a desire to perform accelerated testing on this mechanism by exposing the polymer to gasoline at 60 C (140 F) and then perform finite-element analysis on various molded assemblies. This required stress-strain curves of polyethylene at 60 C after the material had absorbed gasoline. Unfortunately, no such curves existed.

This brings us to the third point in this effort for more clarity on material properties. The market must demand better from the material suppliers. Inertia is a powerful influence, and material suppliers have been living on data sheets for a long time. There will need to be a concerted effort on the part of the consumer, the processors and end users who are designing parts and selecting materials, to ask for a more complete picture of material performance.

Many years ago, I was having a conversation with a material supplier about why more complete performance profiles were not provided to those who need them. I was told, “We would provide it, but we don’t think people would understand it.” While I doubt that this was a genuine response, it is true that the solution is an educated market.

Finally, if all else fails, you can generate the data you need yourself or engage someone to do it for you. There are many testing laboratories across the world that have the equipment needed to create the specimens and perform the tests that will generate these advanced data sets. No new technology is required to accomplish this. Yes, there is a cost. But there is also a cost, a much greater one, to investing in finite-element analysis software, and then plugging in erroneous values to generate a lot of images that look good but bear no resemblance to reality.

Cost reduction starts in the earliest stages of development and it is aided significantly by certainty about the properties of the materials we work with.

ABOUT THE AUTHOR

Mike Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe, LLC, is based in Sedona, Ariz. He has 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

Robust Rotational Viscometer

Versatile viscometer line said to offer robust measurement, repeatability and reporting.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreDual-Mode Portable Thickness Gauge for Packaging

Hand-held “pen” measures sheets, containers, panels, large parts with magnetic or capacitance mode; controlled by Bluetooth phone app.

Read MoreRedesigned Laser Scanner Boasts Improved Accuracy, Resolution, Versatility, and Efficiency

Nikon Metrology’s new LC15Dx is ideal for efficient measurement and inspection of manufactured components including intricate plastic parts.

Read MoreRead Next

MATERIALS: The Problems with Single-Point Data: Part 9

Time—and not just temperature—governs the behavior of materials under load. Both must be considered when evaluating a polymer for an application.

Read MoreMATERIALS: The Problems with Single-Point Data

In plastics, notched Izod and Charpy test results have been complicated by the way they are reported.

Read MoreMATERIALS: The Problems with Single-Point Data--Part 6

Data sheets can be limited in the information they provide on how the material performs at elevated temperatures.

Read More.jpg;width=70;height=70;mode=crop)