Medical Molder Cuts Resin Dust to Boost Quality & Output

As a result, part yields are boosted from only 3% to 60% or more.

When Jeff Replogle first inherited an injection mold for an ultrasonic transducer component, his company had no cosmetic issues molding the eggshell-colored parts. Then the color was switched to gray, and the problems started.

“It was just a struggle,” says Replogle, a process technician for Sound Technology Inc., State College, Pa. “We tried different things with the tool, and we got a little bit better, but the dust was just killing us cosmetically.”

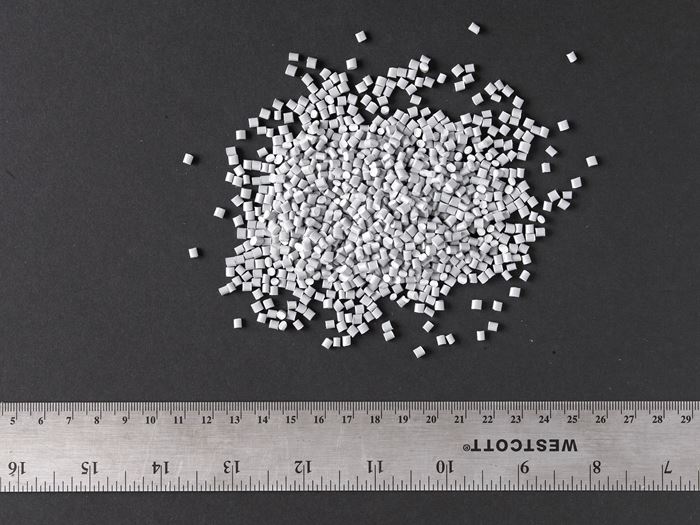

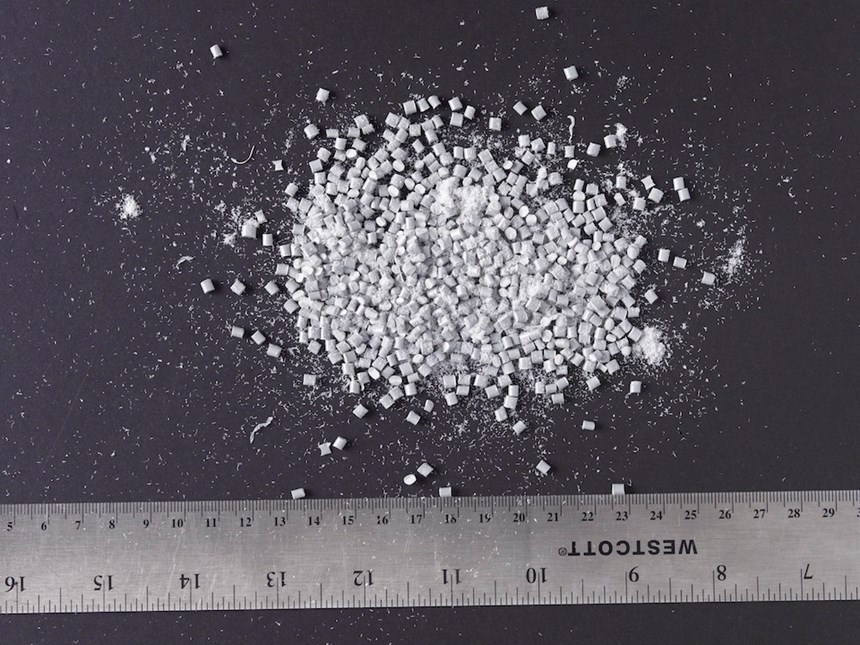

The material in question is a rigid TPU supplied in gray-colored pellets by a custom compounder. Once the color switch happened, the presence of dust—and embedded black particulate in the pellets—rose dramatically, eventually leading to an entire lot of material that produced no acceptable parts.

“Our parts need to be pretty much 100% cosmetically perfect,” Replogle states. “We’d run two-and-a-half bags of material through, and our yields would be like 3% out of all those parts.”

“The DeDuster paid for itself in two runs. That was the best $5000 this company has spent in a long time—a long time.”

After identifying the increased dust levels as the issue, Replogle undertook online research of dedusting equipment and contacted Ryan Buskey of Polymer Systems Solutions, a manufacturers’ representative, who eventually put him in touch with Pelletron Corporation, Lancaster, Pa., and Robert Tausendfreund, a Pelletron sales engineer. Pelletron undertook a free test of the material, with Replogle shipping the company a 50-lb bag, and Pelletron sent back a detailed test report.

Working towards a desired flow rate of 15 lb/hr and removal of all dust, Pelletron’s testing utilized three different methods—ASTM D1921, ASTM D7486, and FEM 2482—to isolate dust, fines, and streamers down to 1.6 microns. After the test, dust level was lowered from 177 to 50 ppm, with product loss to the collector of just 0.025%.

Sound Technology ran the dedusted 50-lb bag and immediately saw yields of 40-45%—miles above previous returns. Impressed with the test run, the company purchased a C-20 DeDuster from Pelletron and saw immediate improvements.

“The unit cost $5000,” Replogle says, “and it paid for itself in two runs. That was the best $5000 this company has spent in a long time—a long time.”

The C-20 has a compact design that allows it to be mounted above an injection machine’s feedthroat. But to allow two dedusting runs—pre- and post-drying—Replogle has set up the unit to operate offline in conjunction with a dryer. Under this regimen, Sound Technology has seen a spike in yield from 3% to 60% or more.

“Our cosmetic standards are super-tight,” Replogle says. “We’re allowed a couple of small black specks in the parts—like 0.010 in. diameter or smaller. You really can’t see them, but to the end user it makes a big deal when you have a nice clean attractive part; and this deduster let’s us do that. It’s just phenomenal.”

Related Content

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

-

Record Reshoring Rates in 2022

Reshoring and foreign direct investment (FDI) in the third quarter marked their highest ever level, eclipsing the previous record set in the second quarter of 2022.

-

DuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

(2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)