Modular ‘Adaptable Automation’ Makes IML More Economical

Five years ago, in-mold labeling was just gaining traction among North American injection molders as a one-step approach to decorating without secondary operations.

Five years ago, in-mold labeling was just gaining traction among North American injection molders as a one-step approach to decorating without secondary operations. Since then, IML has been adopted by only a handful of North American molders, though they say their business has been brisk. Penetration of IML into injection molded food packaging is still no more than 5% here, though in Europe injection molding IML accounts for an estimated 85% to 95% of food packaging applications.

IML’s penetration in North America may get a boost from recent developments in flexible IML workcells using modular “adaptable automation” that allows molders to spread their hardware investment over multiple applications.

Modular or flexible IML systems are designed to help molders whose orders are not large enough to warrant purchase of a dedicated system designed to handle a specific part and a specific label. “With a flexible solution, the molder can adjust to market shifts and take advantage of idle manufacturing time, and can carry out smaller IML production runs that otherwise would be too small to justify a system,” explains Paulo Gomes, Husky’s business manager for packaging. A flexible IML system could be used to penetrate new market segments or to experiment with new designs, he adds. “Your initial investment in the equipment can now be spread out over several projects.”

New flexible IML systems have been developed for single-face molds, stack molds with separate parting lines that mold different parts, and rotary stack tools that can produce different parts or multi-shot IML parts. “With a modular system, you invest once and can run a range of part shapes and label types. Conventional systems are more rigid, so a new part or label is likely to require an entirely new IML system,” says Claes Abrahamsson, marketing director for IML Technologies AB, a Swedish supplier of robotics and other IML equipment.

WHY GO MODULAR?

“Many dedicated IML systems stand idle 30% to 60% of the time because the orders are not big enough to fill up the line,” says Wolfgang Czizegg, CEO of Waldorf Technik, a German IML automation supplier that is a global leader in modular IML systems. Last year, it formed a North American subsidiary called Waldorf Technik Inc. to handle sales and service of its high-speed robotics and automation systems for medical and packaging products.

A dedicated system usually consists of a fixed label magazine designed to handle one label type for one part type. Flexibility is limited to very minor changes in label shape, source note. They say that a “semi-flexible” system allows for some adjustment to the label size and location on the part, and the ability to work with family molds.

Modular systems generally allow the user to change the configuration of the automation as well as the end-of-arm-tooling (EOAT), dummy cores for labels, label magazines, and mold cores and cavities. Flexible systems with interchangeable tooling can be changed from one to two, four, six, or eight cavities. They can switch from round to square containers. And they can run different label shapes and label types (PP, PE, multi-layer or paper). The mold also runs without labels.

On the other hand, a modular IML molding cell may cost a molder up to 20% more initially than dedicated automation. A two- or four-cavity flexible IML cell designed for fast cycles could cost $120,000 to $155,000, including the robot, conveyor, guarding, EOAT, and label magazine. A four-cavity system typically holds cycle times of around 5.2 to 5.4 sec—the same as a dedicated system.

One believer in modular systems is North America IML Containers in St. Placide, Que. “Demand for IML is growing every year, and we launch more and more products every year,” says Christine Bouveret, sales manager. Since 2004, North America has tripled the number of presses in Quebec and opened a second plant in Le Mars, Iowa, that produces only IML products. The firm sees flexible IML systems as critical to its success.

“We build our own IML systems, and each press has one. With our R&D department, we developed our own robotic systems, from flexible systems for small-volume projects to dedicated cells for big projects, such as the Land O’Lakes spreadable butter container.

“We saw a demand in North America in the butter market for an oval, European style container with IML,” adds Bouveret. “So we developed a generic line with three different dimensions for several butter products.” The different sizes can be run on the same flexible IML cell.

Whether dedicated or modular, industry sources say that the largest molds built for IML so far have 32 cavities for flat lids, either in a 2 x 16 stack mold, or a single-face mold. The highest cavitation for containers is 2 x 8.

SINGLE-FACE FLEXIBILITY

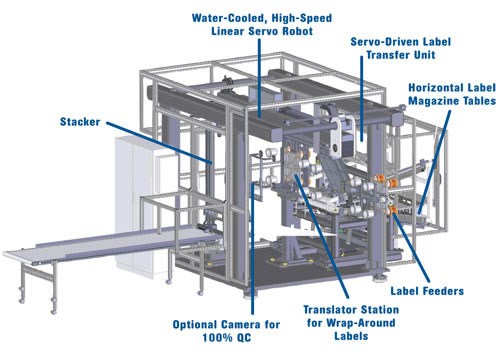

A new modular IML solution primarily for single-face molds is the Highflex IML system from Waldorf Technik. It allows change-out of dummy cores for labels, the label magazine, and robot EOAT. The system is offered in three principal versions: with a single-face robot for inside/outside (core-side or cavity-side) part gating; with a stack-mold robot for inside- or outside-gated parts; or a combination system that can run with either single-face or stack molds.

The system comes in a range of adjustable automation configurations. Hence, it is possible for users to switch from labeling a lid to applying a five-sided label to a container. Typical designs are 2 x 12 for lids and 2 x 8 for wrap-around labels. However, systems are envisioned with up to 64 cavities for small products. There may also be developments in the future for IML barrier containers, says Czizegg.

The system uses a water-cooled, high-speed, servo-driven, linear robot and different types of translator stations that load wrap-around or flat labels onto dummy cores. There is also a magazine table, a label-feed mechanism, a servo-driven label transfer unit, and a part stacker.

To change over the system, users buy a new automation module that corresponds to the label type and cavitation they wish to run. Waldorf guarantees a changeover time of no more than 30 min. The module costs 15% to 20% as much as a whole new IML system. The Highflex IML design uses high-speed, water-cooled servo drives for the main-axis automation movements. Users can store and retrieve up to 99 program sequences. Czizegg says a highflex IML can be delivered in 12 to 15 weeks, compared with 20 to 30 weeks for a dedicated system.

STACK MOLD METHODS

A new turnkey flexible IML system imposes no penalty on cycle time because the automation does not move into the mold parting line for label placement and part removal. It was unveiled at the Fakuma show in Germany last year by Gram Technology, a specialist in rotary stack tooling. SpinStack IML (SSI) is the product of a consortium of Gram and several partners that develop flexible systems for either single-component or multi-component injection. “With SSI, actions such as label placement and part removal occur concurrently with injection, but outside the mold while the mold is closed,” explains Jes Gram, president of Gram Technology.

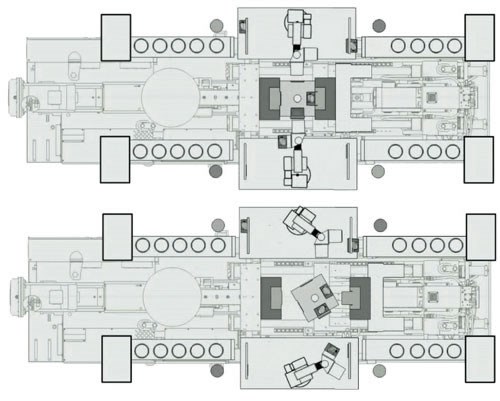

Gram’s SpinStack tooling concept utilizes one or more columns of four-sided core sets that make up a rotating center stack between the stationary and moving platens. The center stack indexes in 90° intervals. The turning mechanism, servo motors, and all of the components are self-contained in the mold assembly, so the technology can be used in any standard press (see Learn More box).

The SSI IML system is designed especially for molding and labeling on two levels of a stack mold. The center platen makes a 90° turn in one direction then reverses and makes a 90° turns back in the opposite direction. Gram’s SpinStack technology usually makes four 90° turns going in the same direction for a 360° operation.

The SSI consortium was formed in 2007 between Gram Technology and SET Group, a Danish turnkey IML system supplier. IML toolmaker Modern Mold Technology (MMT) in Bulgaria joined the consortium to manufacture the SpinStack system with interchangeable cores and cavities, while automation was provided by Kuka Robotics. Taiwan-based injection machine maker Asian Plastic Machinery Co. is the first SSI machinery partner. Gram also has agreements with other IML equipment and label suppliers. The goal is to offer turnkey SSI systems worldwide in partnership with a variety of qualified press builders, moldmakers and automation companies, says Gram.

SSI systems can currently produce up to 5-liter containers and lids, but Gram plans to supply systems for up to 15L containers and lids. “The total cost of an SSI system making and labeling both lid and container will be approximately 30% less than a comparable conventional IML system, and the SSI takes up less floor space,” says Gram.

The SSI system demonstrated at the Fakuma show employed two Kuka 6-axis robots, one handling part take-out and label placement for the lid, the other for the container. Part removal and label insertion was within 4.5 sec while the mold was closed. “SSI allows the user to use more time for part cooling or to ensure label positioning in the tool,” notes Gram.

SpinStack tools can also assemble parts in-mold (using patented double-cube technology) via snap-fits, welding, or overmolding. SpinStack can also be used for in-mold decorating with paint films or in-mold painting (see Learn More).

THINKING THINWALL IML

Toolmaker StackTeck introduced a new technology for lightweighting injection molded parts made with or without IML. StackTeck’s new Thin Recess Injection Molding (TRIM) process, reportedly enables thinning the part beyond conventional thinwall approaches, cutting part weight 20% to 40%. The patent-pending technology features a special core design having raised surfaces that thin out sections or panels of the container, says StackTeck general manager Jordan Robertson. “The tool design involved a lot of flow modeling to yield a lighter part without significant loss of topload strength,” he notes.

This approach is suitable for use with high-flow polyolefins, says Robertson. The technique yields parts featuring thin and thick panel sections in the walls and bottom of the container. Panels of the wall can be as thin as 0.011 in. and thicker wall sections may be 0.02 to 0.025 in. TRIM part designs accept IML labels quite easily, says Robertson, whereas conventional post-mold labels don’t adhere as well to the alternating thin and thick sections.

Robertson says the strength-to-weight ratio of the TRIM made part is as good as or better than a conventional part. He claims TRIM actually improves part rigidity and wall strength. TRIM can be used with single-face or stack molds.

StackTeck showed a 32-oz polypropylene container with a tamper-evident rim made by TRIM. It had a flow length of 5.74 in., which would yield an average length/thickness (L/T) ratio of 300:1 with a conventional wall thickness. But the TRIM process created panels as thin as 0.011 in., which corresponds to 500:1 L/T, says Robertson. The thin panels covered half of the part’s side and bottom, for a 20% weight reduction.

StackTeck offers TRIM tools separately or as part of a turnkey IML system. StackTeck added a new IML pilot cell last year at its Brampton facility for prototyping IML projects. The system consists of a Netstal Synergy 3500 injection machine and a robot from CBW Automation that can be configured for different parts. The cell handles wrap-around labels up to 28 in. long, and also includes a multi-purpose mold base.

Another new super-thinwall IML concept is the first application of the MuCell microcellular foaming process from Trexel to a packaging application. This Super Light Injection Molding (SLIM) concept was commercialized in 2006 in Europe by Autobar Packaging Group, now part of Veriplast International of France (see Learn More). SLIM combines ultra-thin-wall molding with an extra-thin five-sided in-mold label developed by Veriplast. The label is five-layer, 38-micron PP film, half as thick as typical in-mold labels. Such thin labels reportedly enable Veriplast to get perfect bonding with lower injection temperature and pressure.

Veriplast produces 500-g PP margarine tubs in 4+4 stack molds on 385-ton presses at 150 million/yr at its plant in Ravensburg, Germany. The product was previously made on 550-ton presses. Use of the MuCell process reduced melt viscosity up to 60%, dropped process temperatures by up to 140° F, decreased molding pressures by 50%, and cut clamp-force and injection-pressure requirements by 15%. MuCell helped trim wall thickness by 0.4 mm and part weight fell from 15.21 g to 14.23 g while achieving a lower standard deviation. Topload strength was lowered 15%, but it still met performance requirements.

MORE IML NEWS

New automation for IML includes Wittmann’s W727 Flex side-entry robot, which can handle two different parts simultaneously, such as a cup and lid. Wittmann offers four variations of its IML robot/EOAT configuration based on the W727: option C for wrap-around labels, option L for flat lids, and option SM for stack molds. “To change over from one configuration to another requires just a modification of the end-of-arm-tooling—which takes less than 10 minutes,” says Jerome Empereur, packaging product manager at Wittmann-France, where the company’s IML competence center is located.

Ranger automation introduced a new multi-arm automation system for high-speed IML, featuring a 4-axis servo robot for label presentation, a 3-axis servo side-entry robot for label insertion and part removal, and a 4-axis servo robot for finished part stacking. “The key to the system’s flexibility is the first-ever programmable EOAT head for the side-entry robot, making it adaptable for different numbers of mold cavities and adjustable for different label pickup and placement positions,” says John Campbell, national sales manager. The system works with single-face or stack tools.

Ranger also offers flexible IML automation in the form of a label presentation table that allows changeover for different sizes of label trays or cassettes. Locating dowels maintain the trays in previously taught robot pickup positions. Robot EOAT is typically built for a specific label size and mold contour, but is designed to be readily changed over with quick connections on the tooling mount plate, static-charge cables, and pneumatic plumbing.

Ranger’s newest development is an IML Robot Retrofit Kit to upgrade existing robots to handle dual EOAT for label insertion and part removal on the same robot arm. It also provides static-charging capability. Also new is a special dual-EOAT and servo-wrist combo for standard top-entry robots that quickens setup, improves precision, and cuts cycle time for running IML parts. Campbell notes that modular IML systems can actually cost less than a dedicated system by such means as manually replenishing the label magazine and using existing standard robots rather than ultra-high-speed models where possible.

Husky recently collaborated on development of an IML system that uses the label to add barrier performance to a package, reports Paulo Gomes. An example of this approach would be using a film label containing EVOH. “There is not yet a commercial application, but preliminary results on barrier improvement and system reliability tell us this will be an important contribution to packaging,” says Gomes.

A new Quick-Change Set (QCS) flexible system allows use of different label magazines and grippers, and hence different label types and geometries, to be molded in the same machine and mold concept,” says Abrahamsson at IML Technologies. It can be designed with different numbers of cavities to produce parts from 100 cc up to 18L in high or low volumes. The company has also developed an approach for wrap-around IML on molded tubes—cylindrical parts with 0° taper.

Beck Automation in Switzerland provides a complete Quick-Change-Product Set, with very fast and easy setup (less than 30 min). Beck introduced a high-speed IML robot with an Inline-Handle-System to produce labeled pails and handles in the same mold.

Sepro America offers side-entry robots for specialized high-speed IML, with in/out times as fast as 0.4 sec. However, Bill Geddis, who heads up IML development in the U.S., suggests that conventional overhead cartesian (beam) robots suit the vast majority of IML applications in North America and offer greater flexibility. “If you size the robot to the press, it can handle just about any part you might mold in that machine, whether it involves IML or not.”

Hot-runner supplier Yudo-Star of Korea, showed off its first IML automation system at the International Plastics Fair (IPF) in Tokyo last fall. Its new Y-Pac system is designed for low cavitation, entry-level IML. It offers some flexibility in the end-of-arm tooling and label types.

Ranger automation introduced a new multi-arm automation system for high-speed IML, featuring a 4-axis servo robot for label presentation, a 3-axis servo side-entry robot for label insertion and part removal, and a 4-axis servo robot for finished part stacking. “The key to the system’s flexibility is the first-ever programmable EOAT head for the side-entry robot, making it adaptable for different numbers of mold cavities and adjustable for different label pickup and placement positions,” says John Campbell, national sales manager. The system works with single-face or stack tools.

Ranger also offers flexible IML automation in the form of a label presentation table that allows changeover for different sizes of label trays or cassettes. Locating dowels maintain the trays in previously taught robot pickup positions. Robot EOAT is typically built for a specific label size and mold contour, but is designed to be readily changed over with quick connections on the tooling mount plate, static-charge cables, and pneumatic plumbing.

Ranger’s newest development is an IML Robot Retrofit Kit to upgrade existing robots to handle dual EOAT for label insertion and part removal on the same robot arm. It also provides static-charging capability. Also new is a special dual-EOAT and servo-wrist combo for standard top-entry robots that quickens setup, improves precision, and cuts cycle time for running IML parts. Campbell notes that modular IML systems can actually cost less than a dedicated system by such means as manually replenishing the label magazine and using existing standard robots rather than ultra-high-speed models where possible.

Husky recently collaborated on development of an IML system that uses the label to add barrier performance to a package, reports Paulo Gomes. An example of this approach would be using a film label containing EVOH. “There is not yet a commercial application, but preliminary results on barrier improvement and system reliability tell us this will be an important contribution to packaging,” says Gomes.

A new Quick-Change Set (QCS) flexible system allows use of different label magazines and grippers, and hence different label types and geometries, to be molded in the same machine and mold concept,” says Abrahamsson at IML Technologies. It can be designed with different numbers of cavities to produce parts from 100 cc up to 18L in high or low volumes. The company has also developed an approach for wrap-around IML on molded tubes—cylindrical parts with 0° taper.

Beck Automation in Switzerland provides a complete Quick-Change-Product Set, with very fast and easy setup (less than 30 min). Beck introduced a high-speed IML robot with an Inline-Handle-System to produce labeled pails and handles in the same mold.

Sepro America offers side-entry robots for specialized high-speed IML, with in/out times as fast as 0.4 sec. However, Bill Geddis, who heads up IML development in the U.S., suggests that conventional overhead cartesian (beam) robots suit the vast majority of IML applications in North America and offer greater flexibility. “If you size the robot to the press, it can handle just about any part you might mold in that machine, whether it involves IML or not.”

Hot-runner supplier Yudo-Star of Korea, showed off its first IML automation system at the International Plastics Fair (IPF) in Tokyo last fall. Its new Y-Pac system is designed for low cavitation, entry-level IML. It offers some flexibility in the end-of-arm tooling and label types.

Related Content

DuraTech Industries Licenses TactoTek’s Injection Molded Structural Electronics (IMSE)

The custom graphics manufacturer specializing in in-mold and printed electronics now has the rights to sell, design and produce parts that use TactoTek’s intellectual property.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreKurz Opens New Plant in Vietnam

The maker of decorative thin films invested 37 million euros in the new 60,000-m2 plant in Quy Nhơn, which joins regional production facilities in China and Malaysia.

Read MoreBorealis and Bockatech Showcasing Ultra-Lightweight Reusable PP Cups

Use of Borealis PP and Bockatech’s EconCore next-generation foaming technology yields thin-wall, robust and fully recyclable cups.

Read MoreRead Next

In-Mold Assembly: The New Frontier for Multi-Shot Molding

The drive to eliminate secondary operations is pushing multi-shot injection molding a step farther—toward assembling separate components in the tool via snap-fits, welding, and co-molding of incompatible materials.

Read MoreHow IML ‘Cuts the Mustard’ in Germany

The lightweighting advantages of in-mold labeling in times of soaring resin costs are highlighted by the experience of Germany’s largest mustard maker.

Read MoreIML is for Large Parts, Too

The same economic and functional advantages that make in-mold labeling (IML) a growing trend in injection molded packaging are expanding its uses in large parts for durable goods as well.

Read More

.png;maxWidth=300;quality=90)