Mold Micro Parts Just One Pellet at a Time

Here is a closer look at the unusual micro-injection molding press that was reported briefly in our October issue.

Here is a closer look at the unusual micro-injection molding press that was reported briefly in our October issue. Because it molds parts the size of sesame seeds, the manufacturer has dubbed it the Sesame series. It is the first venture into plastics molding machinery from Murray, Inc. (also known as Medical Murray Inc.), Buffalo Grove, Ill. Murray is a consulting engineering firm that designs medical parts and custom-builds special machinery to produce them. It had built molds for micro-sized plastic parts but found no suitable machine for molding them. So it built its own.

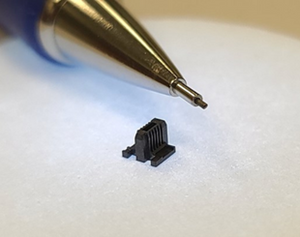

The Sesame machine is designed for precision molding of parts from 0.0004 to 0.40 sq in. area and weighing as little as 0.0001 g, says Brent Roland, director of sales and marketing. Parts can have walls as thin as 0.001 in. The firm offers two models for thermoplastic molding and one for liquid silicone rubber (LSR). Each model comes in two shot-size ranges.

Thermoplastic models come with 0.4- or 1.7-ton clamp force and shot capacities ranging from about 0.082 g to 0.580 g. The LSR press has a 0.4-ton clamp (1.7 tons optional) and shot capacity of about 0.22 or 0.75 g. Injection-pressure ranges from about 29,700 to 50,800 psi for thermoplastics and 21,000 psi for LSR. All units offer injection speeds up to 1250 mm/sec, clamp daylight of 232 mm, minimum mold height of 82.5 mm, and clamp stroke of 150 mm. The machine handles a maximum mold size of 90 x 95 mm. Overall machine size is 24 x 54 in. x 64 in. high.

Designed for clean-room use, the machines are built of stainless steel and anodized aluminum. They use no lubricant or hydraulic oil. They operate on 120V AC current and 90-psi shop air. Roland says the machines can mold any thermoplastic, including LCPs. Nominal base price is $60,000.

One pellet at a time

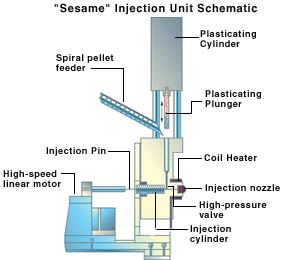

Figure 1 shows the Sesame injection mechanism. A stepper motor drives the pellet feeder to deliver as little as one pellet for each plasticating cycle in order to minimize residence time and chances of material degradation. Instead of a screw—which would hold too much material—the press has a heated plasticating cylinder with a plunger. The resin melts in the hot cylinder, and then the air-driven plunger (10 mm diam.) pushes the material into the injection chamber. There, a linear servo motor drives a needle-thin (1 to 3.5 mm) injection plunger. A high-pressure valve separates the plastication and injection sections, and a shut-off nozzle prevents drool. Controls provide two steps of injection speed and holding pressure. Operator interface is a color touchscreen PC.

The LSR (or LIM) models feed two-component silicone materials from 50-cc cartridges. Features include integral fluid cooling of the shut-off nozzle and two-zone electrical mold heating. The Sesame machine can be switched from thermoplastic to LIM molding in 20 min.

Figure 2 shows the clamping mechanism, which is driven by dual self-aligning pneumatic cylinders. Molded parts are removed with air-driven ejector pins and core pulls. Murray designed a parts-handling system for one customer in which vacuum tubes suck parts out of the mold and transport them to a container.

At least three machines have been sold since 1998 for applications like molding tips or fittings onto catheter tubes, in-line plastic/metal assembly, and electronic component manufacturing.

Related Content

Innovative Micro-Molding From Minnesota Machine Shop

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreNew Machine Range Features Adjustable Clamp for Micromolding

The Boy XS E, successor to the XS series, features servodriven pump drives and different clamp configurations, as well as a special mold holder for optional micromolding operation.

Read MoreIMM Cells Display Communications, Energy Measurement and Energy Recovery

NPE2024: Wittmann will feature five injection molding machines incorporating its range of robotics and auxiliaries, with all products employing industry 4.0 communications, energy measurement and a brand-new red color.

Read MoreMatrix Tool: Welcome to the Family

In its 50th year, Matrix Tool applies moldmaking and injection molding expertise, plus a long family heritage, to high-precision jobs that many would deem impossible.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More