Mold Performance: Tap Into the Power of Data Collection

Collecting core data in a transparent way allows molders to drill into the true cost of tooling issues and develop real goals to keep production flowing.

Face it—trying to analyze mold performance and maintenance data in generic ERP systems is an exercise in futility. Collecting mold performance and repair history in “maintenance stories” or journal-type entries using non- standard language in the “Repair Comment” text field is typically useless in terms of being able to accurately and quickly measure it—and really use it. In other words, the ability to see unscheduled mold stops, product defects, and mold function issues along with associated costs that are broken down and sortable does not exist with an entry like “fixed it”—or “done it” or “Completed Preventative Maintenance (PM)”.

This article will discuss the power of collecting core data (unscheduled mold stops, mold and product defects, corrective actions) in a manner that allows complete cost transparency and the ability to set goals and targets based on frequency and cost issues that interfere with production.

At the MoldTrax maintenance training center, we have heard hundreds of stories from companies that attempt to perform root-cause analyses to reduce or eliminate issues that affect production. A noble cause, but only worthwhile if the root-cause analysis is being performed on the “right” problems.

Among injection molders, there are hundreds (if not thousands) of issues that, on the surface, are all seemingly worthy of a spending the time—and money—to perform an in-depth analysis. The problem is that many of the issues are not really that critical when compared with the overall picture—they just happen to be ‘hot” on that particular day. Without the ability to drill into the true costs (tooling, labor, lost production) of all issues, molders end up guessing about the severity of a given issue.

Most molders simply do not have the time to spend resources on guesses, then hope for a payback. They need to know exactly which mold and which issues the tool room needs

to target to effectively reduce maintenance costs and improve mold performance.

MOLD MAINTENANCE

This can only happen when data is collected using standard terms for unscheduled mold stops, part and mold defects, and corrective actions— and then have the ability to drill in to these high-level terms to see exactly what tooling and labor dollars are being spent to keep molds running reliably and efficiently.

To demonstrate the power of using standard terms, we have put together a collaborative collection of data using standard terms from our MoldTrax data base from 12 different companies that agreed to be a part of this survey. Although the companies differ in products produced and types of molds run, much of the language used is similar, making a comparison even interesting as to what kinds of things ail us as molders.

To set the stage, here is how the average company in our survey of 12 U.S molders (serving the medical, packaging, and automotive markets) over a three-year range from 2012-2014 stack up:

- Mold type: 4–128 cavities (60% hot runner).

- Repair technicians: 8

- Presses: 35

- Molds: 415

- Total mold stops: About 70/wk per company

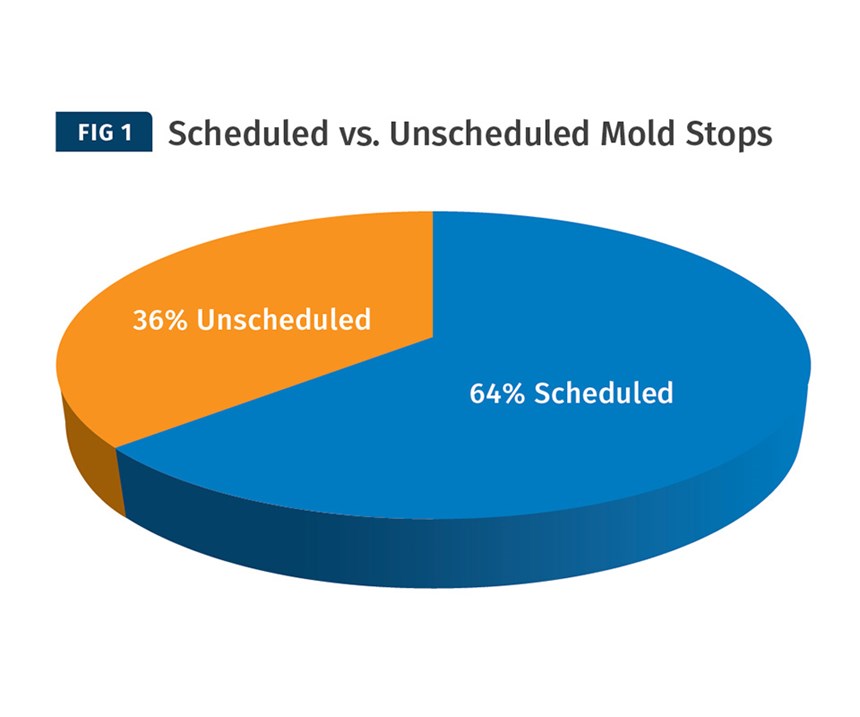

- Total mold stops (over three years): 39,731 (mold-repair work orders; see Fig. 1)

- Unscheduled stops: 14,420

- Scheduled stops: 25,311

On a per-year basis, the numbers look like this:

- Total mold stops: 3311 (or 69 total stops/wk)

- Unscheduled stops: 1202 (or 25/wk)

- Scheduled stops: 2109 (or 44/wk)

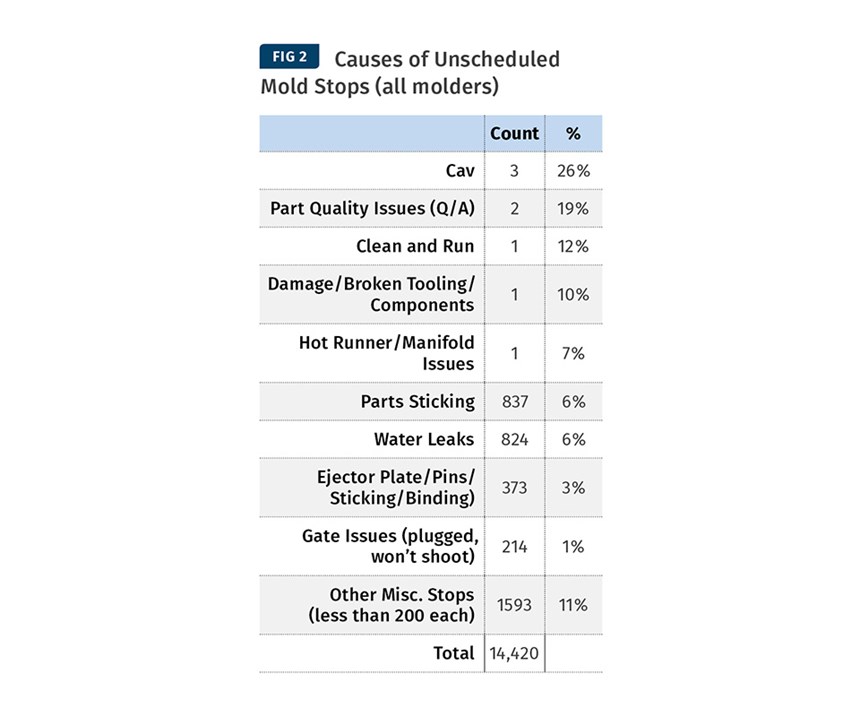

Clearly the majority of companies are suffering unscheduled stops through non-scheduled PMs while attempting to keep cavitation efficiencies at accepted company levels (see Fig. 2). Collecting this type of data makes it easy to sort and filter on the molds related to these specific stop reasons and to quickly determine what molds and issues are costing lost time and tooling.

Drilling deeper, we see that “flash” is the main cause of unscheduled stops (see Fig. 3). Here we do the same thing as above: Sort on flash to see what specific flash defect term pops up, and which molds suffer from it. From here it’s a matter of choosing the target based on what specific tooling is involved and how much in labor dollars are required to fix the defect.

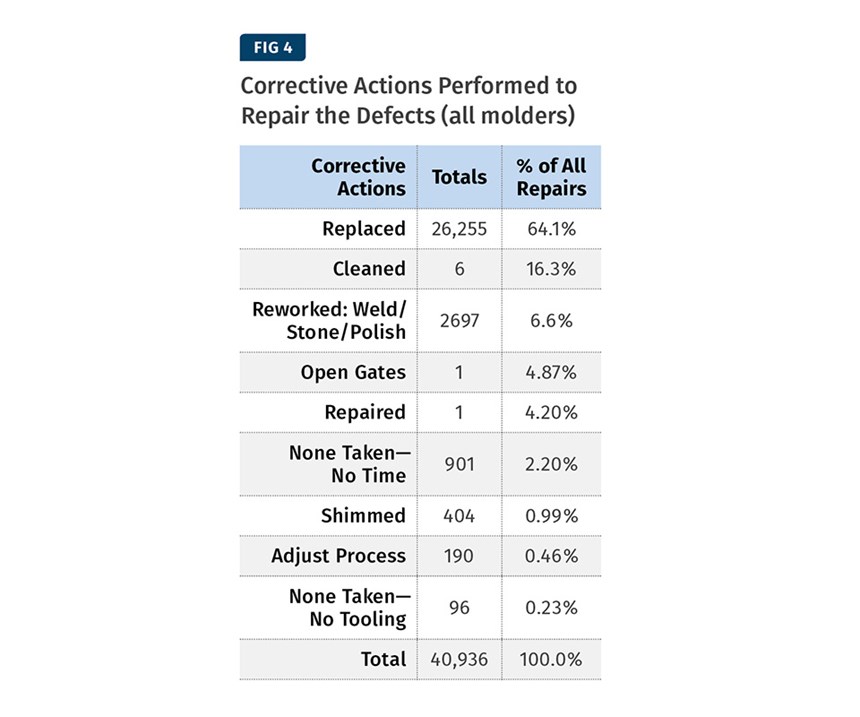

Now that we can see what kinds of issues stop molds prematurely and reduce production (part defects), let’s take a look at what types of corrective actions the toolrooms perform to repair these issues. Once again, the use of standard corrective-action terms makes it possible to see what we do in shops.

From a shop efficiency perspective, we can see that the many corrective actions (see Fig. 4) involve the term “replacing” as the number- one fix. Dig into this also. Ask the question “replacing what?” Tooling?

If so, what tooling? Heaters, seals, interlocks? It will be easy then to compile a list of heavy hitters and publicize it on the white board in the tool room for all to see and monitor.

Every mold that comes into a shop to be worked on has issues that need to be monitored and compared with all molds to set real targets so that repair technicians can be aware of them during PMs or for root-cause analysis. Unless the technicians know about them, real measurable improvement will not take place. Also, in our efforts to be more proactive, we need to realize that every mold has a specific weakness that determines what level of PM should be performed and what frequency to maximize mold/tooling life and product quality. Exactly what that is, and how much not doing so costs us, can get lost in typical day-to-day operations where fire- fighting the hot job of the day is the pre- vailing culture.

Develop a list of standard terms to use and post them by the shop PC. Real communication and mold-performance and maintenance-efficiency improve- ments can only take place when everyone speaks the same language.

ABOUT THE AUTHOR: Steve Johnson is the president of MoldTrax Maintenance Solutions, Ashland, Ohio. MoldTrax supplies innovative and cost-effective maintenance solutions for mold repair through specialized course work, hands-on bench training, maintenance software, maintenance products, tool room designs and maintenance efficiency auditing. Contact: (419) 281-0790; steve@moldtrax.com; moldtrax.com.

Related Content

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreRead Next

Mold Maintenance Training Eases Molder's Growing Pains

Automation Plastics in Aurora, Ohio (automationplastics.com), is a 32-year-old custom injection molder with 50,500 ft² and 30 presses from 35 to 700 tons.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More