Molded Spool Specialist Sees Growth Opportunities in Extrusion

On Site

Spools, reels, and more spools…and now custom profile extrusion has been added to the mix.

Spools, reels, and more spools…and now custom extrusions, too. That’s the blueprint for continued growth at Pittsfield Plastics Engineering Inc. in Pittsfield, Mass.

The company started in 1968 as a moldmaker but in short order branched out into injection molded spools and reels. Its founder, David Chiorgno, sold the business in 1997 to Thomas W. Walker, the firm’s current president/CEO; Tom Holmes, chairman and financial advisor; and two other investors. Chiorgno, described by Walker as an old-school moldmaking craftsman, stayed on with the company until his retirement in June, and then passed away suddenly in October.

MOLDING PROPRIETARY PRODUCTS

Pittsfield Plastics’ primary business is still proprietary spools and reels. These come in a wide array of styles and sizes and are sold to the wire, tape, cable, solder, textile, and other industries. Operating out of more than 80,000 ft² and running around the clock for five days a week (sometimes even seven days, depending on demand), Pittsfield produces millions of pieces year from both engineering and commodity materials.

Typical applications for the spool family are coaxial cable, speaker wire, THHN wire, CATV wire, hose, tubing, chain, and rope. Four flange diameters are available. All come with adjustable barrel traverses to achieve optimum spool capacity. Pad printed flanges are also available.

Most recently, the firm expanded its already diverse line, adding 14-, 16-, 18-, and 20-in. spools and reels to meet demand for uses with rope, insulated wire, cord, etc. “We’ve fielded enough calls from prospects looking for reels to hold rope, insulated wire, and other products requiring these larger sizes, that we expect high demand for these new reels,” Walker notes. The new sizes come in three pieces, which allows for plastic or corrugated barrels.

A complete line of wire spools and reels for coarse, fine, and ultra-fine gauges is available. Material and design options range from lower-cost shipping reels to multi-use process reels.

Pittsfield Plastics also produces a complete line of solder spools for packages ranging from 0.25 to 50 lb. It has an automated process that can apply labels to these spools straight out of the press. Other value-added capabilities include two-color pad printing; assembly, hand fitting, ultrasonic welding, chemical bonding, custom packaging, and bar coding.

Other molded products include tape spools and snap-fitting shells for tape widths from 0.5 to 2 in. Several flange diameters offer options for different tape lengths. Tape and film cores are another Pittsfield Plastics specialty. The company also molds dye tubes in several sizes. A built-in nesting feature eliminates the need for dye-tube separators. Plastic king bobbins are another staple product for packaging 4 to 64 oz of thread. The bobbins with sure-grip surfaces are offered in many colors and with customized printing. Large breakdown reels are shipped unassembled to save on freight costs. This patented design allows Pittsfield Plastics to ship more than three times the number of reels that would be possible if they were preassembled. These reels can be assembled by the customer with no tools.

“We’ve been growing steadily,” says Walker, whose experience in reels can be traced to the 10+ years he spent at Sonoco Crellen prior to purchasing Pittsfield Plastics. “We try to achieve the right balance of cost, quality, and on-time delivery—and to treat every customer and every order, large or small, with the same attention.”

The numbers support Walker’s statement: In the years he’s been at the helm, Pittsfield Plastics’ sales have increased almost fivefold to their current level of more than $12 million. The firm recently added 12,000 ft² of manufacturing space, and additional expansions and improvements under way. “With our upgraded facility, comprehensive equipment to meet everyday and unique customer needs, new product and service offerings, and an unchanged commitment to filling every order efficiently, we anticipate continued growth,” Walker says.

“Even as we modernize our equipment, technology, and facilities, it’s our business attitude that really makes our products and relationships work. We have a lot of experience at this company, but no matter the project, our entire team gets involved.” That “all-hands-on deck” philosophy was illustrated during Plastics Technology’s visit, when Nick Roth, director of business development, got his hands dirty on the plant floor, cutting and deburring samples of newly developed extruded cores for a customer trial.

Pittsfield Plastics supports its spool and reel business with 37 injection presses ranging from 75 to 750 tons. These include a 75-ton press with a 6-oz shot size for thermoset molding and two brand-new 528-ton machines from Chinese supplier Haitian. Molds run up to 32 cavities. Most are outsourced, though the firm maintains a toolroom that can design, build, and repair any mold it runs.

GROWTH IN CUSTOM PROCESSING

Pittsfield Plastics lately has balanced its strong position in proprietary spool and reel molding with more custom work. “In the last two months alone we have added 30 new custom jobs,” states Roth. One unique custom molding job came from an Australian company that invented a multi-purpose, portable sink molded of HDPE. Pittsfield Plastics is also doing more work in custom molded cores and housings for filtration devices.

The company’s decision back in 2009 to venture into extrusion perhaps offers the most significant growth opportunity. “We used to farm out the barrels for our reels and spools, and initially we got into extrusion to bring those capabilities in-house,” recalls Walker. “We now extrude all of our barrels here. We also extrude film cores, another complement to parts of our reel and spool business. But the real opportunity to grow in the future is in custom extrusion.”

Pittsfield Plastics’ extrusion division, aptly named Plastic Extrusion Co., currently has four lines ranging from 2 in. to 3.5 in. diam., with the largest extruder capable of producing a profile up to 6.5-in. diam. Lines are equipped with vacuum-sizing and cooling and four-sided pullers, which are said to provide more precisely round tubes than standard two-sided pullers. Pittsfield Plastics designs all its tooling in house, and runs a wide range of materials, including PS, ABS, PE of all kinds, PP, PVC, and SAN, among others. End markets include packaging, wire, tape, film, industrial, home construction, recreation, and avian protection. In the latter case, Pittsfield Plastics developed a profile used by electric utility companies to shield birds, squirrels, and other creatures from high-voltage wiring.

States Walker, “We’re pursuing the custom extrusion business with the same qualifications and quality as we’ve been providing on the proprietary side of the business since we started.” These include ISO 9002.2000 registration, consultation on material selection, specialty gauging according to the application, warehousing arrangements by agreement, and on-time deliveries, Walker adds.

The firm’s current line of core tubes are available in diameters up to 6 in. Wall thickness can be from 0.050 to 1 in. and lengths from 0.50 in. and up.

Post-extrusion services include precision slicing and punching, CNC machining, screen printing, and ultrasonic welding. Applications include plumber tape, business-machine tape and precision paper cores, utility spools, thread take-up cores, and dental floss.

The firm also produces a line of custom HIPS tubes in diameters from 1/8 to 6 in. and wall thicknesses from 0.030 to 0.25 in. Applications include film, tape, paper, and textile manufacturing, as well as protective packaging, electrical distribution, and conduit repair.

Its line of profiles ranges in wall thickness from 0.030 to 0.25 in. at tolerances of ±0.010 in. Profiles can be round, triangular, square, or with U- or L-Channels. End uses include cement-pole protectors; T-dividers, and packaging.

Related Content

Teel Adding Capacity, Bumping Pay for Hourly Workers

Teel growing to meet market demand, meaning increased employment opportunities for the area.

Read MorePut Some ‘Lean’ into Your Profile Extrusion Process

With everyone struggling to find talent, there are ways to reduce operator interaction with the process by applying some lean manufacturing principles.

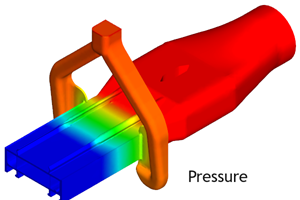

Read MoreUpdated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)