Molder Adopts ‘Semi-Smart’ Automation

R&D Plastics finds new and more sophisticated ways to use robots.

R&D Plastics, a custom injection molder in Hillsboro, Ore., mirrors in many ways the trends in automation among molders in North America. The firm’s plant has evolved from simply demolding parts to pairing up robots of different types for insert feeding, orientation and placement in the mold. The firm builds its own end-of-arm tooling (EOAT) for labor-saving tasks such as flexing living hinges. It is now looking to automate secondary operations with collaborative robots (cobots). The firm is also looking to automate setup of robots and other cell devices along with the injection machine. And it is looking beyond “hard” automation to ways of automating data transfer between machines and central computers.

Last month’s report on the firm’s many programs supporting local plastics education and training helps explain why R&D Plastics has been described as a pillar of the Northwest manufacturing community. It is owned and run by CEO Rod Roth (son of Merrill Roth, founder of another storied Northwest molder, Grant & Roth Plastics) and Sal Gonzalez, v.. of operations. R&D Plastics was started in 1996 (after the sale of Grant & Roth to SPM) and is now approaching record sales of $8 million. It operates from a 28,000 ft2 plant with 60 employees and 19 presses from 40 to 720 tons.

Evolving Automation

“We are a medium-size molding company with the staff and tools of a much larger company,” says Ron Knowlton, v.p. of business development. The firms’ capabilities include in-house engineering and elastomeric molding, overmolding, insert molding, structural foam, and more. While the majority of its business is “mold-and-ship” work, there is also a growing volume of value-added secondary operations such as sonic welding, hot stamping, digital printing, assembly, adhesive bonding, and fastener inserting. It has outside sources for plating, painting and hydrographic coatings.

Furthermore, the custom molding business must accommodate a typical eight mold changes in 24 hr, while still operating at 98% good-parts yield and 80% capacity utilization. “Everything we do changes on a weekly basis,” comments Don Altorfer, maintenance manager and automation engineer.

These factors help explain the molder’s move to increasing automation. Most of its presses have a servo robot—and one cell has two—along with additional automation, including insert feeders and conveyors. Until recently, the plant’s robots were all Star and Yushin models, but starting in 2015-2016, R&D Plastics began buying Wittmann Battenfeld robots and now has five, including two W818 and two W843Pro models and a dual-arm W818S,.

Matthew Barnett, general manager of R&D Plastics, expects more purchases of Wittmann robots to follow. “We’ve been very impressed with their service and support,” says Barnett. “They are one of the best service-oriented companies we’ve worked with.” His sentiments are echoed by Altorfer, who visited Wittmann Battenfeld’s West Coast Tech Center in Placentia, Calif., for three-day comprehensive robot training. He was able to come back to the molding plant and train his own staff on what he learned there. In addition, Jason Cornell, Wittmann’s West Coast Regional Manager for Robots and Automation, comes on-site every couple of months to continue training and demo new features. (Not incidentally, R&D Plastics just bought its first Wittmann Battenfeld injection press, to accompany its existing stable of Toshiba and Sumitomo (SHI) Demag machines.)

R&D Plastics appreciates the flexibility of the Wittmann robots to accommodate the rhythms of a custom molding business. The traverse beam comes pre-drilled and tapped every 5 in. along the underside, allowing for fast adjustments and constant position shifting for constantly changing processes.

As Barnett describes the current phase of automation at R&D Plastics, “Today, it’s less about putting parts in a box, and more about what I call ‘semi-smart’ automation.” An example is one insert molding cell in which metal inserts are fed by a vibratory feeder (built in-house) to a conveyor. That leads to a high-speed SCARA robot, which places the inserts in a precise location and orientation for pickup by a Wittmann linear robot that places them in the mold and demolds finished parts.

Another example is some hard/soft overmolding cells in which two presses are placed side by side, one to mold the rigid substrate and one to overmold with TPE or TPU, using a robot to transfer between the two.

R&D Plastics has a do-it-yourself culture, and it builds a lot its own equipment, including a special CNC sonic welder originally designed by Merrill Roth. The firm also makes some of its own robot EOAT. An example is a tool for flexing living hinges fresh out of the mold, saving the need for a person to perform that task. The EOAT was 3D printed by a new dual-extruder, filament-fed Pro2 printer from Raise3D Technologies, Inc., Irvine, Calif. (raise3d.com).

Though it accounts for only 10% of the firm’s business today, the growth of value-added secondary operations has R&D Plastics thinking about automation there, as well. “We’re starting to look at cobots for jobs like sonic welding,” says Barnett.

“Today, it’s less about putting parts in a box, and more about what I call ‘semi-smart’ automation,” says R&D Plastics’ general manager, Matthew Barnett.

He adds that automation has benefits for employee morale and hiring. “By implementing the new automation, we are able to reduce some of the more simple mundane tasks and leverage our employees to operate in more of an inspector/packer role and less as a machine operator.” And then there is the “cool” factor that appeals to younger workers. “That is very true with our mold setters and junior process technicians. They see an opportunity to learn about automation that they will carry with them throughout their careers, be it here at R&D or wherever they might end up.”

Data Automation Grows, Too

Savvy molders today agree that automating the flow of real-time manufacturing data is just as important as automating the flow of products and components. That’s the case at R&D Plastics, where Ron Knowlton is proud of the firm’s ERP system from IQMS, which he says, “provides—among other things—real-time information on exactly what’s happening on the molding floor and in value-add, as well as storing information about mold and machine adjustments and preventive maintenance.”

Another step forward has come with the purchase of a Wittmann Battenfeld SmartPower 300 servohydraulic injection press and associated auxiliaries. This “smart work cell,” says Barnett, is equipped to store and retrieve job setups for not just the molding machine, but also the robot, hopper loader, additive feeder, and mold-temperature control unit (TCU). This capability, which the supplier calls Wittmann 4.0, will help make frequent job changes even faster and easier.

Related Content

ZAG Equipment Sales Partners with Portugal’s Plasdan of Portugal

Under the agreement, ZAG will sell and service Plasdan’s add-on injection units and fully electric rotary tables for multicomponent injection molding.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

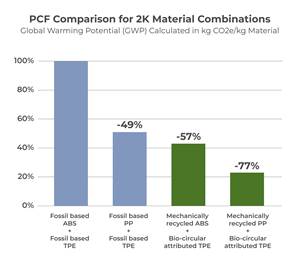

Read MoreMore Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)