Molder Gets Hermetic Seal, High Yield with Servo Welder

Supplier of power protection systems avoids redesign of molds by replacing pneumatic ultrasonic welder.

A specialist in power-protection systems, Schweitzer Engineering Laboratories (SEL), Pullman, Wash., recently avoided both costly redesign of its injection molds and boosted yield by opting to replace its pneumatic ultrasonic welder with a new ultrasonic servo welder.

SEL designs and builds digital products and systems that protect power grids around the world. The company offers a variety of fault indicators for use on subsurface or pad-mounted transformers, subsurface or pad-mounted switchgear and sectionalizing cabinets, junction boxes, and splices.

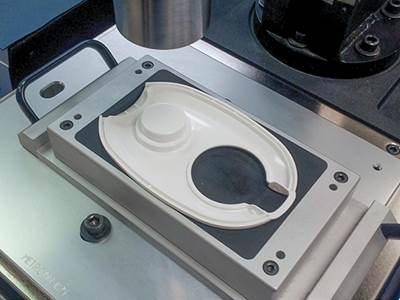

Recently, SEL was having difficulty assembling one of the many reset fault indicators it molds. The product is made of Makrolon 2607 PC from Covestro, Pittsburgh, and the project entailed welding the clear lens display screen to the body of assembly. Because the product is intended for harsh, submersed, and corrosive environments, the hermetic seal of the ultrasonically welded housing is tested to sustain temperatures ranging from -40 C (-40 F) to 65 C (140 F).

SEL was experiencing low yield from its pneumatic ultrasonic welding process. The welds were inconsistent, resulting in leaking, non-hermetic welds. SEL conducted several Design of Experiments over a three-year period, and the results always pointed to the same small welding process window with high down speeds and very short weld times. SEL engineers first suggested redesigning molds to get even flatter welding surfaces. However, before proceeding with this option, multiple sets of parts were taken to the Dukane Applications Lab in St. Charles, Ill.

There, Dukane’s 20 kHz iQ Series servo-controlled ultrasonic welding system with Melt-Match technology was used to perform tests on sample parts. iQ Servo welder graphs showed the part was acting like a spring because of a hollow area under the weld zone and was collapsing faster than the horn movement, resulting in inconsistent and leaking welds. As a result, it was necessary to use varying weld speeds.

Ken Holt, sr. application engineer at Dukane states, “Makrolon 2607 welds very well when the initial weld speed is slow and is gradually increased over the weld distance. Although old pneumatic systems are capable of varying the force during the weld, the rate of change

is restricted due to the time required to move air in or out of the air cylinder. However, the servo system is capable of accelerations of 50 in./sec2—equivalent to changing speed by 1 in./sec in 0.020 sec. Dukane’s patented Melt-Match technology further expands this capability by allowing 10 discrete velocity values during the weld process.”

The repeatability of the servo welder and the welding and graphing functions make it easier to set up new welding programs.

iQ Servo’s ability to precisely control and vary the weld speed (velocity of the collapse of the weld joint) proved the key factor for welding leak-proof parts. Numerous setups were attempted until the weld velocity profile was optimized. The final speed profile setting from 0.020 to 0.090 in./sec proved to be very robust and allowed for variations in weld distance and amplitude without adversely affecting weld results.

Melt-Match’s Melt-Detect component was enabled to ensure complete initiation of melting before prompting the horn to initiate downward movement. The overall “U” shape of the force curve indicates that high force was applied at trigger; horn movement was initiated when force dropped to a preset value signaling that the part had begun to melt and collapse; finally, force and horn movement were increased gradually, providing consistent strong bonding.

Says Rick Lewis, SEL’s manufacturing engineering supervisor, “The new servo welder is integrated into a robotic cell and is working flawlessly. The repeatability of the servo welder and the welding and graphing functions make it easier to set up new welding programs. It reduces the engineering time and the number of scrap parts required to set up a new welding process.”

Related Content

Eco-Sustainable Pad Printing Ink

Incups GN Series passes the ISO cytoxicity test and complies with EuPIA.

Read MoreNext-Generation Fully Electric Ultrasonic Welding System

NPE 2024: Rinco new eMotion servo-driven machine is available in 20 kHZ and 35 kHz frequencies.

Read MoreUltrashort Pulse Laser Marking System for Medical Devices and More

FOBA’s F.0100-ir creates deep black markings on medical plastics, stainless steel and titanium.

Read MoreAdvanced Hardcoat Technologies for Automotive

Momentive’s SilFort technology geared to auto exterior applications.

Read MoreRead Next

Servo Welder Gives Molder More Control

Applications that require near-hermetic seals are now easily achieved by this electronic contract manufacturer.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)