Molder Saves Energy and Maintenance Headaches With New Type of Quiet-Running Chiller

The first plastics molder to use a radically new kind of chiller was looking for improved reliability to keep its plant running 24/7.

The first plastics molder to use a radically new kind of chiller was looking for improved reliability to keep its plant running 24/7. It found what it needed in an oil-free chiller design that has only one moving part. Drastically reduced noise levels and 40% energy savings confirm that it made sense to try something different.

“We had a problem. If the chillers go down, the whole plant goes down. And we didn’t trust the chillers,” recalls Walter Pipan, engineering manager for Universal Plastic Mold (UPM, Inc.) in Baldwin Park, Calif., near Los Angeles. One of the largest custom molders on the West Coast, UPM’s 100,000-sq-ft plant has 25 machines from 300 to 2000 tons.

Until recently, chilled water was provided by an older 150-ton, water-cooled chiller with six reciprocating compressors and a 106-ton, water-cooled chiller with two screw compressors. The firm also had an air-cooled reciprocating chiller in reserve, though its condition was questionable. Pipan and the production staff were concerned because the main reciprocating chiller was becoming less and less reliable and required frequent inspection and repair outages.

UPM went to Thermal Care, Inc. for a solution to the growing threat of chiller failure. Pipan was also interested in reducing energy usage for the chilled-water operation, since California has some of the highest electricity rates in the nation. Thermal Care recommended removing the water-cooled and the standby air-cooled reciprocating chillers and replacing them with two chillers featuring a novel type of centrifugal compressor manufactured by Danfoss Turbocor Compressors Inc. of Montreal. Thermal Care and Danfoss Turbocor had worked together for over a year to develop chillers based on the revolutionary Turbocor compressor.

Quiet & super-efficient

The compressor’s sole moving part is the shaft with twin impellers, which rotates on magnetic bearings that eliminate friction and wear and reduce noise. They also require no oil, avoiding associated maintenance and disposal problems and costs. The variable-speed motor can operate at high efficiency over a wide range of loads.

Until recently, Turbocor compressors were used mainly in HVAC applications. Dan Mason, North American sales director for Danfoss Turbocor, sees chillers for plastics molding as a promising application. “Long running hours at variable loads and a need for high reliability are places where our product really shines. Because of the oil-free design and the variable speed, we can stay in an efficiency sweet spot all the time.”

In early 2003, the water-cooled reciprocating chiller was replaced with the first Thermal Care chiller. In June 2004, the air-cooled machine was replaced with a second Thermal Care package. The existing screw chiller remains on standby status.

The Thermal Care chillers at UPM each have two 70-ton Turbocor compressors. An important aspect of the installation is remote monitoring capability. This allows either UPM or service specialists at Thermal Care remote access to 79 points of diagnostic information per compressor, including the status of the compressors, electronic expansion valves, and condensing-water-regulating valves. Explains Tom Benson, Thermal Care’s v.p. of sales and marketing, “We can quickly assist with any chiller performance questions by having one of our service specialists from our home office communicate directly with the chiller through the internet. Both Thermal Care and the customer can view temperatures, pressures, volts, and amp draws; log and save data; adjust setpoints or control parameters; view alarm history and captured data at the time of a fault; view power demand profile; and make PLC program updates.”

A remarkable aspect of the Turbocor compressors is their exceptionally quiet operation. Peak sound level is 71 dbA, much quieter than their predecessors. Walter Pipan was surprised at the drastically lowered sound level in the outdoor mechanical yard where the chillers are located. “I came out into the yard during the installation and asked when they were starting the compressors. They told me they were already running. You can actually hold a conversation here now, where you couldn’t when the reciprocating units were running.”

Pipan points out that the new 140-ton chillers have a smaller footprint than the chillers they replaced, thus freeing up space in the mechanical yard.

With the installation of the first chiller, UPM immediately noticed a reduction in the plant’s electricity charges, and installation of the second unit increased that savings. Pipan says, “They are using about 40% less energy than the reciprocating units that we were relying on earlier.” This reduction made UPM eligible for a rebate from Southern California Edison. Although the new chillers cost a little more than ones with screw compressors, Pipan figures they paid for the difference within six months.

After three years with the new-style chillers, Pipan would recommend them to almost anyone: “They run great, and we’ve been really pleased with their reliability.” Bill Stanonis, president of West Coast Industrial Services Inc., Riverside, Calif., which installed the chillers and does the maintenance, says there have been few service calls. “These compressors just don’t require much attention.”

Thermal Care considers the Turbocor design “ideal” for mid-range chilling applications. Its new water-cooled units, first announced publicly in mid-2004, come in standard sizes from 60 to 180 tons. Thermal Care has just introduced remote-condenser air-cooled models that are said to be even more efficient (see box). AEC, Inc., also recently began marketing water-cooled chillers with Danfoss Turbocor compressors in sizes of 120 to 190 tons.

Related Content

Multicoupling Range Extended

Hasco‘s quick-connect system for multiple cooling circuits has added U.S., French and HT versions.

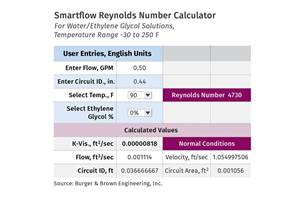

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreFollow These Best Practices When Working With Heat Transfer Fluids

Effectively choosing, operating and maintaining thermal fluid can positively impact productivity in plastics processing.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)