Moving Toward ‘Autonomous Molding’ with a Uniform-Low-Pressure Process

A new low-pressure injection molding process has aroused interest among molders and machine suppliers. In his second article on iMFLUX, the inventor of the process explains how it is evolving to support the overall industry goal of self-correcting molding processes that can compensate for common causes of variation to maintain consistent part quality.

The automotive industry has delivered advances enabling cars to assist the operator in braking to avoid collisions, safely maintain a lane on the highway, even automate operations such as parallel parking. Eventually, your car will drive itself. Similar to these automotive innovations, iMFLUX believes the injection molding industry’s journey to autonomous molding can be accelerated by leveraging the built-in advantages of what we call the “Green Curve,” where controlling the filling process by actual plastic pressure unlocks the ability to deliver many truly autonomous features.

Plastics processors today encounter many barriers to an autonomous injection molding operation. This is because the levers that control the stability of the operation are often varying in ways that are either difficult, or in some cases impossible, for the processor to control. Overcoming these challenges requires: 1) a robust process that can withstand the normal variations in materials, mold, machine, and environment; and 2) a control system that can intelligently adapt to the variations that are outside the normal range of variation.

This is not a wishful fantasy. As discussed below, a process has been developed—and continues to evolve—that can self-correct for variations of up to ±50 MFI units in viscosity, random blocked cavities, leaky check rings, faulty heater bands, and worn screws or barrels—not something a conventional Scientific Molding process can accomplish. (See sidebar, “About iMFLUX.”)

About the Green Curve

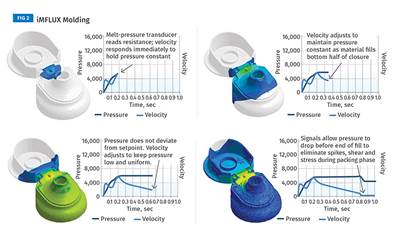

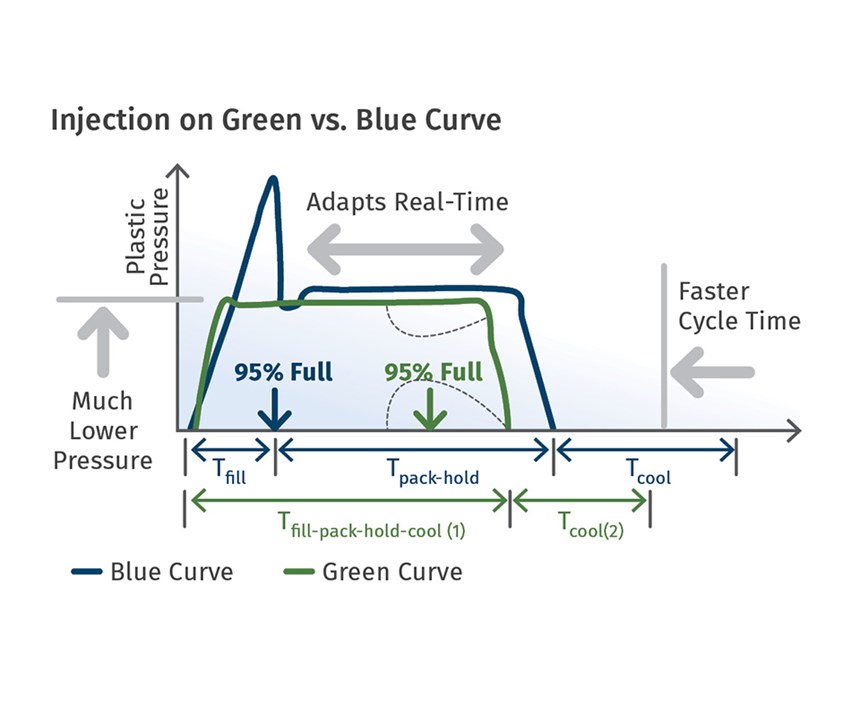

The Green Curve works by filling and packing the mold using a low and constant plastic pressure. The key to making the process work is a proprietary control system that eliminates flow hesitations, packs the part as it fills, and reduces pressure loss within the mold. This allows plastic to flow much slower than conventional processing techniques, and results in a process with lower pressure, shorter cycle time, and the ability to adapt in real time as molding conditions vary. Advantages include improvements in OEE (overall equipment efficiency), greater material-selection flexibility, improved quality, ability to reduce clamp tonnage, lightweighting part designs, and flexibility in running sustainable materials – especially highly variable recycled materials. Figure 1 shows how the Green Curve compares to a typical decoupled molding process (in which control of the filling stage is separated from packing and holding stages).

To repeat the most important point: iMFLUX controls the filling process by maintaining plastic pressure at a lower, and more constant pressure. In so doing, the process is inherently less susceptible to variations that shut down a conventional process, referred to as the “Blue Curve.” The reason the process is so robust is that it actively controls plastic pressure during molding, which is the number-one factor impacting the quality and consistency of an injection molded plastic part. This overcomes the inconsistency of conventionally controlled processing where screw velocity is maintained constant, but plastic pressure varies as material and molding conditions change. When it comes to autonomous molding, the Green Curve is steering the process based on what really matters—plastic pressure—a massive advantage.

iMFLUX can adapt the process to handle variations, even variations well outside of the normal range, much easier than can be achieved with a conventional process. This is possible because the Green Curve is a simple process, essentially pressure and time. On the Blue Curve, adapting to changes requires modifying several variables—injection velocity, transfer position (or cavity pressure), holding pressure, and holding time. What’s more, the holding time itself must accommodate variations that have complex interactions.

On the Green Curve, adjustments are limited essentially to plastic pressure (how much pressure is driving the plastic in to the mold) and time (how long is this pressure applied). The simplicity of the process enables iMFLUX to create highly advanced control algorithms that can handle variations well beyond what is practical on the conventional Blue Curve.

Adjusting for Viscosity Shifts

The ability to reliably process variable materials is one of the industry’s biggest needs, since processors are being asked to run more and more recycled and lower-cost materials. Often these materials have varying viscosity, making them very difficult to handle. The conventional molding Blue Curve is set up to run parts at a static set of process conditions, and as even relatively small material variations occur, process adjustments are needed to maintain part quality. Recent advances in technology have made it easier to manage material variations on the Blue Curve, however, that process is still inherently unstable due to its sensitivity to transfer position and pressure. The Green Curve is much less susceptible to such changes, since it has no transfer position and adjusts in real time to variations in material rheology.

Blocked Cavities A traditional molding process is set to inject a certain volume of plastic into a mold, regardless of the ability of the mold to accept this volume. This can create issues if a gate becomes blocked, or if a part is not ejected completely, leaving nowhere for the plastic to go. Depending on the number of mold cavities and cavity volumes, this will result in bad parts and potential damage to the mold.

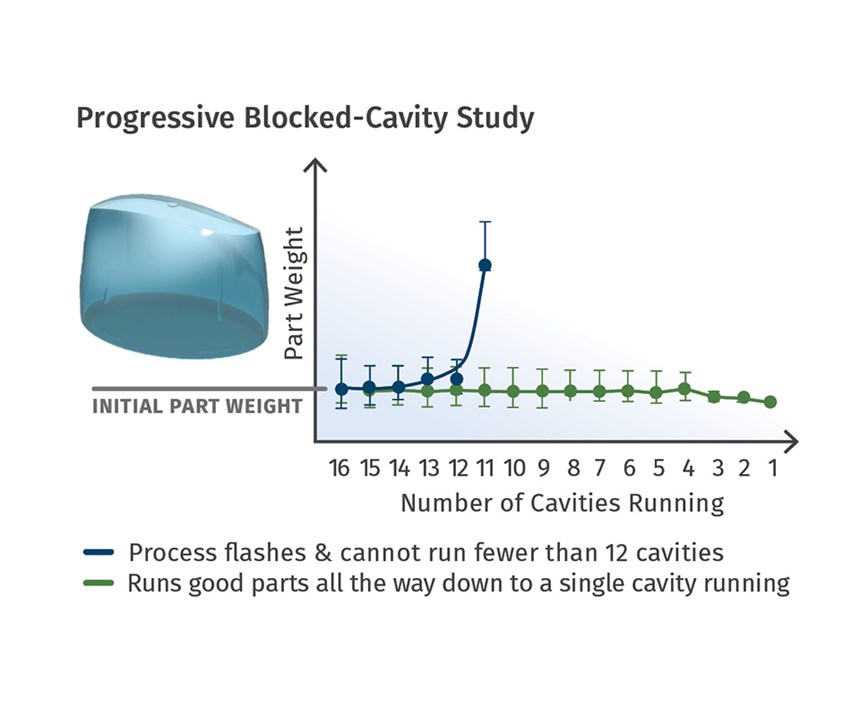

The Green Curve works differently, since it is continuously controlling the process and monitoring plastic pressure. If a mold cavity becomes blocked, the system immediately recognizes this change and profiles the injection velocity to match what is needed for the current state of the mold. Not only does this prevent tool damage, the process actually makes good-quality parts in the remaining cavities. Similar to automated braking on your car, the system understands when to slow the movement of the screw to optimally fill the cavity. This feature is particularly helpful with multicavity molds where the processor needs to keep a mold running at less than full cavitation. In this case, the mold cavities can simply be turned off without the need to develop a new modified process. This is not possible on the conventional Blue Curve.

Figure 2 shows results of a study using a 16-cavity deodorant cap mold, in which cavities were progressively shut off. No process adjustments were made. The conventional Blue Curve part weights immediately began to increase, and the mold could not be burn with fewer than 12 cavities. The Green Curve process could run good parts no matter how many cavities were shut off.

Leaky Check-Rings & Worn Barrels Consistent check-ring functioning is necessary with traditional velocity-based process control to maintain a consistent polymer volume at transfer. Even small variations can cause big issues with part quality. On the Green Curve, a leaking check ring has virtually no impact on the process, since the process is completely reliant on plastic pressure with real-time feedback. If the check ring leaks, iMFLUX simply accelerates the screw to compensate for the leakage. The Blue Curve relies on static process settings and cannot make dynamic adjustments for inconsistent check-ring performance. On the Green Curve, as long as the press can build plastic pressure, a completely repeatable process can be obtained. This is true whether the repeatability issues are consistent shot-to-shot, or sporadic in nature. To achieve truly autonomous molding the process must be able to adapt to these kinds of common variations, or it cannot be effective in achieving a stable, repeatable process.

Steps toward Autonomous Molding

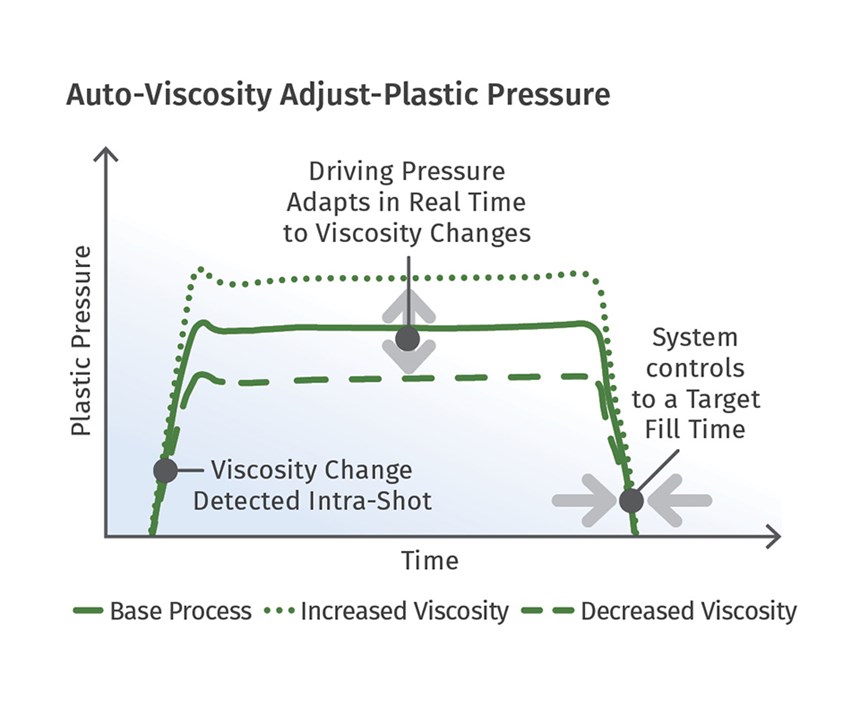

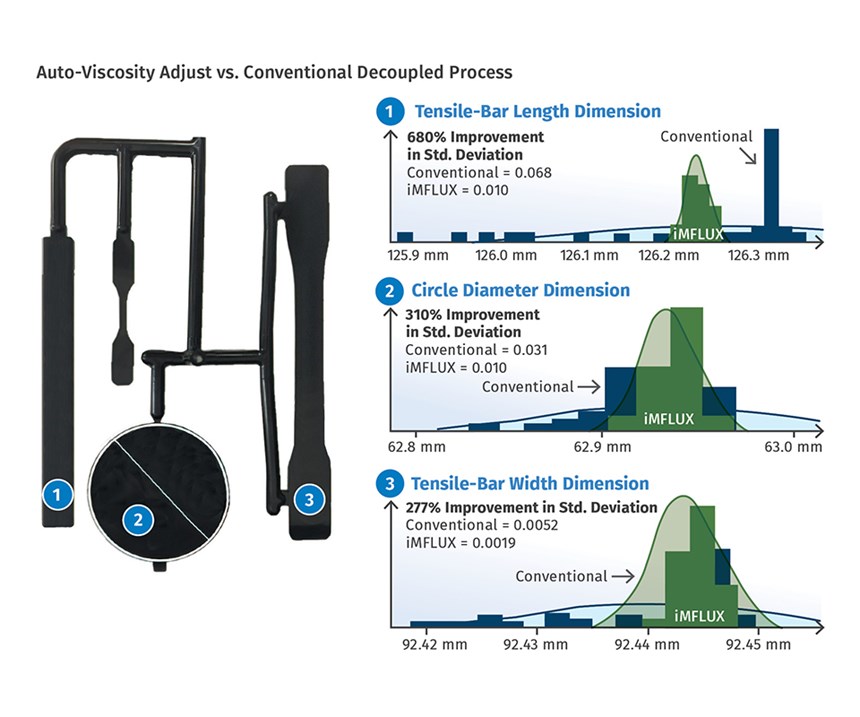

An advanced feature released by iMFLUX earlier this year, called Auto-Viscosity Adjust (AVA), enables the Green Curve to manage even larger variations than the base iMFLUX technology. The new feature can handle viscosity shifts of ±50 MFI or more. AVA works by detecting viscosity changes, then modifying filling pressure to achieve the same filling time shot-to-shot. Similar to cruise control in your car, the process adjusts in real time without needing operator input. This is true regardless of the source of variation, which can include regrind variation, percentage of regrind, colorant changes, moisture level of the material, or temperature variation. Basically, if the machine can melt it, the Green Curve can process it.

To illustrate the capability of the Auto-Viscosity Adjust feature, iMFLUX performed a running conversion from a virgin ABS to a lower quality reprocessed ABS. No process adjustments were made to the conventional Blue Curve process or to the iMFLUX Green Curve process throughout the run. The AVA feature substantially outperformed the conventional molding process for dimensional consistency, thus demonstrating its ability to dynamically adjust to large material variations. Aesthetic improvements were also observed throughout the run, resulting from continuous optimization of filling pressure provided by the AVA technology. Figure 4 provides an overview of the study.

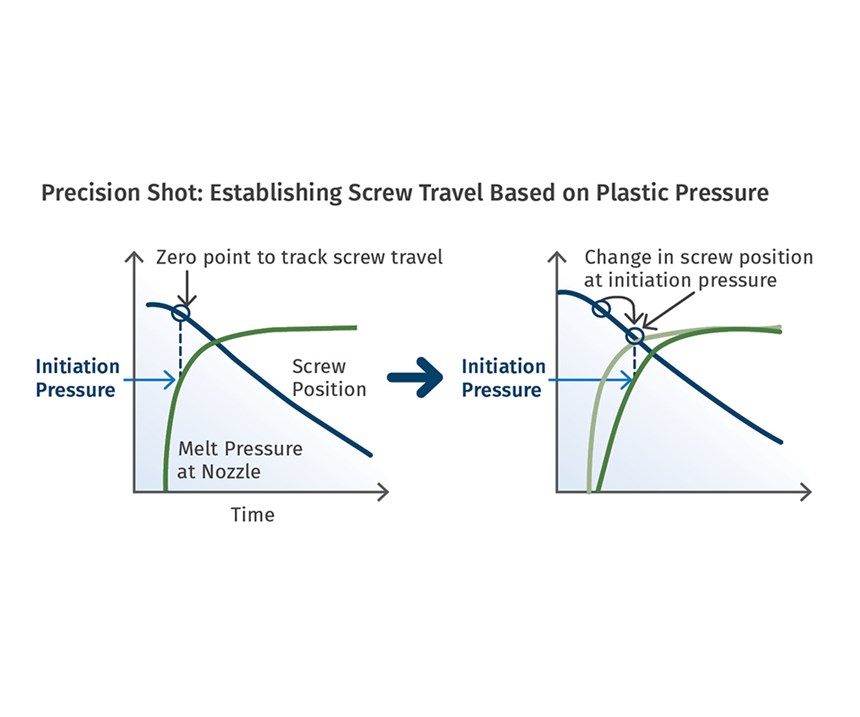

Another feature just released enables the control system to compensate for material density shifts, even shot-to-shot. Called Precision Shot, the technology works by first building shot pressure to a predetermined threshold, followed by metering the shot into the mold (Fig. 5). This feature is only possible when controlling the process using plastic melt pressure, enabling the system to accurately determine that the check ring has seated and that the target compression of the melt has been achieved.

What’s Next?

iMFLUX has a strong innovation pipeline that will enable molding machines to make intelligent decisions on behalf of the operator, ultimately leading to an autonomous molding operation. This vision includes strengthening data-acquisition capabilities, adding learning algorithms to the software, and automating time-consuming and complicated steps such as establishing a process window and intelligently bringing a process up from a cold start or temporary stop. iMFLUX also continues to develop “soft” sensor technology, which derives critical process information without the need for a physical sensor, thus keeping the technology simple and efficient to implement.

About the Author

Gene Altonen has been the chief technology officer of iMFLUX in Hamilton, Ohio, since 2015. He is the inventor of the iMFLUX core technology, and leads the iMFLUX R&D organization. Gene has spent his entire 27-year Procter & Gamble career developing new packaging solutions, including numerous injection molding technology innovations. Prior to the iMFLUX launch, Gene was a Research Fellow, leading major technology developments in the Injection Molding Capability organization within P&G. He holds more than 50 patents and has at least 35 patent applications pending. For more information about iMFLUX, contact 513-973-2042; info@imflux.com; imflux.com.

Related Content

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRead Next

Milacron Is First to Integrate iMFLUX into Machine Controller

Integrating iMFLUX low-pressure process into machine controls is a more economical route to faster cycles and improved part quality.

Read MoreA New Way to Mold Better Parts Faster and Easier

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.

Read More

.png;maxWidth=300;quality=90)