New Die Opens Up New Markets

General Plastic Extrusions Corp. found that out recently in converting a second-hand blown film line that had been used by its previous owner for R&D.

Sometimes all it takes is a die change. General Plastic Extrusions Corp. found that out recently in converting a second-hand blown film line that had been used by its previous owner for R&D. Interestingly, General Plastic turned to a relative newcomer in the field of blown film dies for its upgrade, and as a result now has a foothold in the barrier film business.

Based in Prescott, Wis., General Plastic (generalplastic.com) makes a variety of packaging films and bags, specializing in small runs. An order can be as small as 1500 lb, notes Grant Durhman, president. In that business, quality and ability to change products quickly ranks above throughput on the priority scale.

Back in 2008, General Plastic decided to expand into five-layer films for packaging cheese and other food products. It purchased a used line from another company that was using it only for development purposes. “We went through the learning curve that most film processors experience when they first get into five-layer, but it didn’t take long for us to realize that the die technology we bought was outdated,” says Durhman. “The quality we needed was not there. And the difference between what we produced and what others in the five-layer business had out there was visible.”

General Plastic turned to Premier Dies Corp., Chippewa Falls, Wis. , for an upgrade. Though noted for flat dies, Premier had done some reworks of other dies at General Plastic.

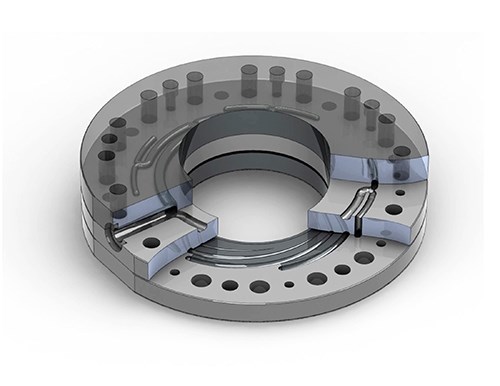

The five-layer die Premier built for General Plastic is a pancake-style unit that uses a set of three round plates to process the flow of each individual layer, explains Steve Jonak, president of Premier. Polymer is distributed around the die between two of the plates with a flow-splitting channel. It then travels through the middle plate via eight holes to the gap between the second and third plates, which contains the spirals cut into the flat side of both plates. Material then travels toward the center pin, and makes a 90° turn upward. The benefits of this design are that each polymer is thermally isolated from the others until they are combined. Use of three plates instead of just two reduces the diameter of the die and the overall size and length of the flow channels.

The die was supplied with 6- and 10-in. diam. lips. It runs on a line using three 2-in. extruders and two 2.5-inchers.

With its original die, General Plastic was producing at a rate of about 150 lb/hr. Durhman and Jonak were hoping for rates of 350 lb/hr on the new die, but it’s said to be running above that for some products. “We’re getting about 16 lb/in. of die circumference, generally speaking, which is good output for what we do,” Durhman says. The die also transitions into and out of nylon structures much faster than the previous version. “And the quality of the film we are making now is measurably better.”

Premier’s production-scale die designs now range from 1 to 48 in. diam. and up to 15 or more layers. The dies incorporate face-to-face mating seal surfaces with no added seals, minimizing maintenance costs. Special radially expanding pins are used to align each plate precisely with the one above it. This reportedly improves the accuracy of each layer’s flow channel and makes the die easier to assemble and disassemble. Each individual plate layer bolts to the one below it for precision assembly.

The entire layer stack assembly is held together with a complement of full-length tie rods, which are said to prevent leaks. There are no slip-fit areas inside the die nor mating surfaces on angles, which are common with nested mandrel designs. The central pin incorporates internal heaters for faster heat-up and for control of the temperature inside the die. In addition, the central pin can easily accommodate air passages for IBC.

In the high-end barrier-film business, General Plastic competes against some industry giants. But it’s undaunted by that competitive challenge, noting that its facility for short runs and quick changeover gives it the edge in plenty of cases. “There are enough crumbs that fall off the table to keep us busy,” as Durhman puts it.

Related Content

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreThe Importance of Viscosity in Melting

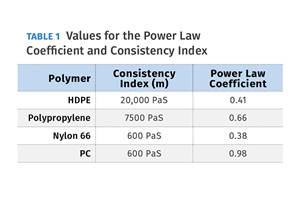

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More