New Machinery &Materials Help Rotomolders Add Value to Parts

Producing solid features in an otherwise hollow rotomolded part and coloring parts in easier and more flexible ways are two new developments highlighted at the January meeting of the Association of Rotational Molders (ARM) in Minneapolis.

Producing solid features in an otherwise hollow rotomolded part and coloring parts in easier and more flexible ways are two new developments highlighted at the January meeting of the Association of Rotational Molders (ARM) in Minneapolis. Other news highlights include the debut of more in-line shuttle and rock-and-roll machines, improvements in lab equipment for prototyping, and new grades of polyethylene, TPEs, and PVDF.

Add a feature with putty

A new way to mold solid features like tabs and flanges onto the inner or outer surfaces of hollow parts relies on an unusual material rather than special hardware. Mold In Graphic Systems unveiled its Three Dimensional Rotomolding Compound (RMC3), a pliable putty that can be manually shaped, roll-formed, or pre-molded into the shape of the desired solid feature. RMC3 is made from a fractional-MI polyethylene and other proprietary materials. Once shaped and placed in the mold—typically in a crevice or area with a tight radius to hold the material in place—the putty does not melt or flow during molding. Instead, it cures and bonds with virtually any PE rotomolding powder, even crosslinked types, says senior v.p. of sales and marketing Scott Saxman. It can be colored and adjusted for flexibility or rigidity.

Users can form the molding compound into flanges, threads, handles, feet, partitions, and mounting tabs. It can also provide reinforcing support to a metal insert or pull pin. Molders can trim cycle time by using the compound to form thick wall sections with less powdered material.

RMC3 also adds greater design freedom. The rule of thumb has been that projecting features in rotomolded parts require an OD of five times the nominal wall thickness to ensure good fill in the mold. With RMC3, that limitation no longer holds.

Better ways of coloring

A new method for coloring polyethylene rotomolded parts involves painting them with a hot spray of molten, colored resin. It eliminates the need to color a part all the way through, which wastes expensive colorant and can affect part properties. It also avoids conventional painting and surface preparation or other methods of post-decorating.

The new spray-coating process is in development at Queen’s University in Northern Ireland and the University of Alicante, Spain. It uses a “jet gun” to simultaneously melt and spray colored polymer powder onto the surface of the molded part. The process requires preheating the part surface and post-heating to smooth out the sprayed coating. The powder can be a dryblend of resin and pigment particles or ground-up colored resin. The coating is the same as the substrate material for good bonding.

Also new is an inorganic, non-hygroscopic antistatic additive for use with dry colors in rotomolding. It reportedly prevents pigment swirl regardless of humidity and also yields a more intense hue than conventional colorants. H2Stat from Teknor Color Co. utilizes metal-based additives that provide sufficient conductivity to prevent static build-up.

Standard organic antistats absorb atmospheric moisture, so they require relative humidity from 15% to 50% to generate sufficient conductivity. Also, they sometimes act as mold releases, causing premature separation of the part from the mold.

In addition, conventional low-melting organic antistats may soften and cause pigment agglomeration, producing specks in parts. Teknor’s H2Stat takes the place of the usual dispersion aids and reportedly prevents pigment agglomerations. More intense color is said to result.

Teknor offers H2Stat in custom dry-color formulations at prices slightly above those of conventional colorants. At use levels of 0.2-0.5%, the new antistats have no appreciable effect on impact strength.

New machine designs

A new supplier of “rock-and-roll” machines has introduced a self-contained, single-arm model suited to short-run production. It heats and cools the mold in a specially designed oven. Cell-Mold LLC, Duncan, S.C., a maker of municipal waste receptacles, developed its Cellular Roto-Molding System for in-house production of rotomolded tops and liners for waste containers. Custom orders for different colors and low production volumes had created problems for its custom rotomolding vendors. The new machine features a 44 x 56 x 66 in. oven for molding parts up to 55-gal size. Users can put several units side by side to produce parts of different sizes or different materials at rates equal to those of more expensive multiple-arm turret systems. Each Cell-Mold system starts at about $45,000.

The unit has a gas-fired oven with recirculating fans. It starts up cold, heats quickly, then cools down fast. The compact oven chamber and fast oven response permit short runs with energy efficiency, says Richard Durant, president. The oven housing has a cooling intake and cooling exhaust port on top. The entire molding cycle takes place within the oven.

Two types of floor-level shuttle machines are new from STP Equipment. The entry-level Storm line features a single molding arm and two or three stations—one oven and one or two cooling/servicing stations. The cooling station is open and uses forced-air fans directly under the mold carts. Spherical arm swing is offered in five models from 80 to 220 in. Users can choose a straight or offset arm, radiating or convection oven, and one or two air or gas injectors. A second mold-support cart or arm is optional.

STP’s new Hurricane line is a more sophisticated series of in-line shuttles in six models with spherical swing from 80 to 160 in. Features include a convection oven with an accordion-style, retractable cooling dome and high-performance blowers for fast cooling. Two sets of interchangeable straight or offset arms are offered, as well as four air injectors. A PLC control with PC interface allows for pre-programmed, multi-level recipes. Technical support through a modem connection is also standard.

Custom Machinery maker NW Rotofab for the first time is building shuttle rotomolding equipment. (The firm also offers independent-arm, turret-arm, and rock-and-roll units.) The shuttle model has an oven and cooling chamber; a second cooling chamber is optional. Standard features include full automation with touchscreen control panels, jog control on all arms for loading and unloading, AC variable-frequency drives, adjustable speed control for major and minor rotation, and forward and reverse indexing of all arms. Air lines on the arm allow users to pressurize the mold. Customized units will be priced around $350,000.

More capable lab units

A new frameless mold design is offered for testing flow, shrinkage, and mechanical properties of rotomolding resins. Available from Plastics Consulting Inc., which developed it with Wheeler Boyce Co., the Flow Gauge Box Test Mold is designed to fit the shuttle lab molding machine sold by Plastics Consulting.

The PTFE-coated tool is made of six separate panels that are machined from aircraft aluminum, which is non-porous and stronger than cast aluminum, eliminating the need for a structural frame. The clamping flange is integral to the mold, and mounting is done with thumbscrews (no tools). The bottom panel of the mold is a shrinkage gauge. The top panel contains the Flow Gauge, a series of 25 cylinders machined into the panel with different heights and inside and outside radii. They show the relative ability of resin to fill complex molds.

Also new is the M-80 single-station clamshell machine from Ferry Industries for prototype or entry-level molding operations. It boasts 20% improved heating and cooling, which occurs in the same station.

New materials

A new “super” LLDPE to be introduced soon by A. Schulman will have stiffness, impact, and HDT levels 30% better than its commercial XL0360 LLDPE. New XL 0370 resin (0.952 g/cc) is suited to large parts such as kayaks.

Rotomolding-grade polyester TPE powders suited for automotive and other applications have been added to the Icorene line from the ICO Polymers Technical Centre in Belgium (a unit of ICO Inc., Houston). The five grades are based on DuPont’s Hytrel TPE. Shore hardness ranges from 35 to 55D.

A new grade of PVDF for rotomolding was developed by AtoFina Chemicals. Kynar Flex 3120-WR is a copolymer that exhibits high purity and corrosion resistance like other Kynar Flex resins but has a higher melt temperature that is suited to rotomolding. The material can be used to make parts for handling chemicals and high-purity water.

Pearlescent or metalized color effects are new offerings from Chroma Corp. Its new line comes as pre-compounded materials in a blue-to-green effect and a white-to-yellow effect. The firm also broadened its Chroma-Granite line of colors with new brown, dark-gray, light-gray, blue, and green. Chroma also has a reformulated black dry color that is now dustless.

New mold releases

McLube Div. of McGee Industries, a maker of semi-permanent release coatings for the rubber industry, now offers five products to rotomolders. Three grades, MAC-784, 785, and 779, are semi-permanent, water-based release coatings. Applications range from general use to difficult-to-release parts and materials. The firm also offers MAC 678, a ready-to-use, all-purpose release, and McLube 1782, a water-based, semi-permanent, touch-up release for PTFE coated molds.

Higher heat transfer than a PTFE coating, as well as ease of application, are pluses claimed for the Black-Maus release coating from Maus GmbH in Germany, offered here by Norstar Aluminum Molds. The black coating contains a proprietary powdered additive that delivers higher heat transfer, which can help lower cycle times.

Related Content

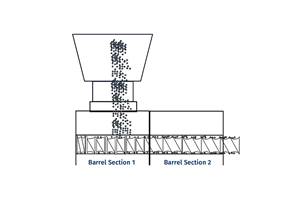

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

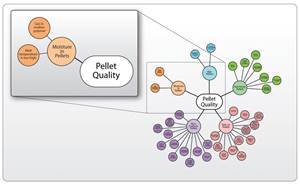

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More