New Plasticizer Chemistry for PVC Excels in Cold & Heat

It’s rare that an entirely new plasticizer chemistry comes along for flexible PVC—especially when it comes with an established health and safety record.

It’s rare that an entirely new plasticizer chemistry comes along for flexible PVC—especially when it comes with an established health and safety record. New Flexidone plasticizers also promise unprecedented high efficiency, extreme low-temperature performance, very low volatility at elevated temperatures, and time and energy savings in processing due to fast gelation at low temperatures.

Flexidone plasticizers from International Specialty Products Inc. (ISP), Wayne, N.J. (ispplastics.com), are based on N-aklyl pyrrolidone chemistry. They are based on about 70% renewable raw materials (fatty amines). According to Hasan Kaytan, ISP new-business development manager, alkyl pyrrolidones were found to plasticize PVC 20 years ago, but this application was not pursued until recently. In the meantime, alkyl pyrrolidones have been used in shampoos, dishwasher detergents, and other cleaners. They have recently been tested in PVC—especially plastisols—by German vinyl resin maker Vestolit and at the University of Cologne.

Four products are commercially available, with chain lengths from C8 to C18. Short to mid-length chains provide high solvating and flexibilizing efficiency, while longer chains lend superior stability and durability to products that must hold up in hot conditions.

ISP recommends Flexidone products for general-purpose use. However, these are premium specialty products costing two to two-and-a-half times as much as standard phthalates. So Flexidone will be used mainly in combination with other plasticizers. Kaytan says Flexidone is compatible with all other plasticizers and ingredients used in flexible PVC. In fact, Flexidone reportedly increases the compatibility of other formulation ingredients—allowing, for example, high levels of inexpensive secondary plasticizers such as chlorinated paraffins or fatty (palmitic, oleic) esters. Flexidone also helps comptibilize high filler loads and can allow increases in filler levels, says Kaytan. In addition, Flexidone products have around 10% lower specific gravity than phthalates, which partially compensates for their higher cost/lb. In fact, ISP claims that total formulation cost with Flexidone is equal to or lower than that with other plasticizers.

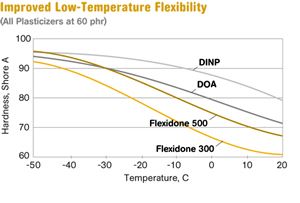

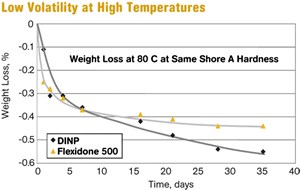

As shown in the accompanying graph, Flexidone 300 and 500 (medium and long-chain) provide better low-temperature flexibility than conventional low-temperature plasticizers such as adipates (DOA). They can provide flexibility down to -70 C (-94 F). Long-chain Flexidone 500 reportedly also provides very low volatility at elevated temperature, comparable to DINP. Water and oil extractability are said to be comparable to phthalates.

Workhorse Flexidone 300 (short-chain) is “by far the most efficient plasticizer in the world,” claims Kaytan, “30% to 40% more efficient than standard phthalates, thus allowing lower use levels.”

He also emphasizes the processing advantages of Flexidone plasticizers, because they are absorbed more quickly and at lower temperatures than many other plasticizers, especially longer-chain phthalates that are being substituted for DOP. In plastisols or dryblends, replacing 15% to 30% of other plasticizers with Flexidone will reduce mix times and temperatures and also provide significant improvements in transparency of clear vinyls, Kaytan says.

Flexidone has been used for more than two years in extruded PVC pencil erasers. Other applications being considered in Europe and Turkey are automotive door seals and thick sheets used in cold warehouses. Plastisols with Flexidone are being developed for disposable gloves and carpet backing. Kaytan notes that ISP has not sought food-contact or medical approvals for Flexidone.

Related Content

How to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreLFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)