New Rubber Types Play Well with Plastics

Plastics and rubber sometimes compete, but they also collaborate.

Plastics and rubber sometimes compete, but they also collaborate. Some new thermoset elastomers from the Performance Rubber business of Lanxess Corp. offer improved processing and performance properties for co-molding with thermoplastics or blending with them for added toughness.

For example, thermoplastic molders are just discovering the potential of a new type of hydrogenated nitrile butadiene rubber (HNBR) commercialized by Lanxess in 2005. Called Therban AT (Advanced Technology), it boasts lower molecular weight as well as narrower MW distribution than other HNBRs, resulting in improved mechanical properties. Most interesting of all, Therban AT has lower Mooney viscosity than previously possible in a hydrogenated nitrile rubber, which allows for easier injection, compression, and transfer molding and extrusion. Furthermore, its easy processing allows use of less plasticizer and more filler, further enhancing properties and economics.

Easier overmolding

HNBR is a specialty rubber with very good resistance to heat, ozone, chemicals, and oil, suiting it well to automotive applications, cable coverings, and various mechanical rubber goods. Until recently, HNBR ranged in Mooney viscosity from 55 to 105. But Therban AT has a 39 Mooney, which allows it to be injection molded into large parts at lower pressures and even into larger and more complex parts than previously possible with HNBR, according to Dr. Boudewijn van Lent, v.p. of Lanxess’ Technical Rubber Products for North America. Examples of potential applications would be progressive-cavity pumps and blow-out preventers for oil wells. The latter can contain up to 500 lb of molded rubber.

Thermoplastic molders are working with Lanxess on two-shot overmolding of rigid nylon parts with an integral rubber gasket. Up to now, rubber/plastic molding has used mainly silicone rubber. Unlike silicone, HNBR has good adhesion to nylon, but its high viscosity made overmolding difficult. Therban AT overcomes that problem, and Lanxess is working with several molders to exploit this compatibility in parts such as an oil filter.

Better toughening

Another new development from Lanxess is the use of neodymium (Nd) catalysts to produce polybutadiene rubber for HIPS. This NdBR was introduced last year and has demonstrated higher toughening efficiency in HIPS. Therefore, around 20% less rubber can be used, according to Tim Rae, head of polybutadiene rubber marketing and logistics for North America. This cost saving prompted quick adoption by HIPS producers in Europe and South America, and U.S. suppliers are evaluating NdBR as well.

The material has the further advantage of gel levels inherently lower than standard butadiene rubbers used in HIPS, which is important to the aesthetic quality of HIPS extruded sheet. NdBR could offer similar advantages in other styrenics such as ABS, though this has not yet been tested.

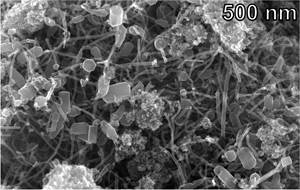

Also new from Lanxess is a unique high-isoprene butyl rubber that contains up to four times as much isoprene as regular butyl rubber. It was developed especially for tire treads, where it can improve wet traction and abrasion resistance. However, Lanxess believes it has interesting potential as a component of thermoplastic elastomers and thermoplastic nanocomposites. “We believe it may offer some unique properties and improved processability,” said Dr. Ralf I. Schenkel, head of global R&D for butyl rubber in Sarnia, Ont.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)