New Sensor Tech Monitors State of the Melt During Molding

Detect ‘true’ melt temperature, viscosity variations, melt density, and much more, throughout the molding cycle.

“Injection press controls today measure parameters like the forward speed of the screw or plunger, the pressure applied, the torque to run the screw, percentage ‘on’ time of the heater bands, and so forth. Those are all machine variables. What they don’t measure is the state of the plastic itself.” According to Michael F. Durina, that’s the key factor limiting molders’ ability to know in real time whether they are producing good or bad parts. It would be much more useful, in his view, to measure such factors as the melt temperature, viscosity, melt density, and total energy input to the melt during each cycle. The good news, Durina says, is that technology has arrived to do just that.

Durina is president of Md Plastics Inc., Columbiana, Ohio, a firm that makes plasticating components for injection molding. He is the exclusive manufacturer and marketer of sensors invented by Fred Buja, owner of FJB PlasTechnology, Rochester, N.Y. The sensors, trade named Temp-Tek, first appeared at NPE 2012. Since then, Durina has been working with Buja (formerly of Eastman Kodak) and a number of molders and machinery OEMs to develop the technology for practical use. Md Plastics developed improved mounting hardware for the sensors and has just released new monitoring software designed to make them easy to use.

SENSING TOTAL ENERGY INPUT

The business end of this patented “thermoelastic” sensor is a spherical bead of two metals, one magnetic and one nonmagnetic, that expands and contracts under the influence of both temperature and pressure. According to Buja, the key principles are that a temperature increase causes a volume increase in the sensor bead, while a pressure increase on the bead decreases its volume, which raises its internal temperature (pressure x volume = temperature).

Durina demonstrates the sensor’s behavior in a video on the firm’s website, in which he inserts a sensor through a puncture in a tennis ball. When he squeezes the ball, the sensor readings rise. Likewise, he says, a sensor simply lying in the open on a desktop will record a change in reading if the atmospheric pressure changes.

The thermoelastic strain on the sensor bead from both temperature and pressure is converted to a temperature output reading, though it should more properly be interpreted as a dimensionless unit of total energy input from both heat and pressure. Durina notes that under conditions in which the melt is under little or no pressure—such as at the end of holding pressure before screw recovery starts—the reading correlates most closely with just melt temperature.

That was the experience of Wayne Staupe, Technology Center manager at Evco Plastics in De Forest, Wis. His group tested one of the sensors in the nozzle of a machine and compared the sensor readings at the end of holding pressure—where, Staupe saw that sensor output stabilized before screw recovery—and found they were consistently at the center of the range of manual readings from a temperature probe in a purged shot taken by a group of technicians. “It was pretty darn good,” Staupe concluded.

SOLVE THE ‘MYSTERY’ OF MELT TEMPERATURE

Staupe would be the first to agree that there has been no economical way to accurately measure melt temperature in the injection barrel or nozzle. A conventional sensor embedded in either location would be influenced by the surrounding steel temperature, and a sensor projecting into the melt stream would be too susceptible to wear or damage. Durina adds that conventional thermocouples are relatively slow to react. (A newly available, flush-mounted infrared sensor is another alternative that may offer fewer limitations—see Keeping Up section.)

“The only practical way to measure melt temperature today is by manually sticking a probe into a purge,” says Staupe. “That’s too inaccurate because it’s subject to a large number of measurement variables.”

Durina thinks the Temp-Tek sensor can finally “solve the mystery of melt temperature.” Staupe agrees: “It’s the best thing I’ve seen for measuring melt temperature inline.” Evco has just purchased two more Temp-Tek sensors for evaluation at the tech center.

The stainless-steel-bodied sensor is typically mounted in a 1.5 mm (0.063 in.) diam. hole in the injection nozzle. Md Plastics developed a compression fitting for the sensor with a PTFE thermal barrier. It screws into the mounting hole and withstands high internal barrel pressures. The sensor is mounted tangent to the melt stream, with only the very tip directly exposed to the melt, and is covered by a film of melt thinner than a human hair, which protects the sensor from abrasion by the melt stream, fillers, etc.

According to Durina and Buja, the Temp-Tek sensor can reveal much more than melt temperature. It can measure the total amount of “work” (energy input) imparted by the machine to the melt throughout the whole molding cycle. Durina reports that a study at Tech Molded Plastics in Meadville, Pa., showed that the shape of the “total work” curve from the Temp-Tek sensor over the course of a cycle very closely matched that of the relative-viscosity output from an RJG eDart system, which calculated “effective viscosity” for the same cycle from injection speed, pressure, and screw diameter. (RJG Inc. is in Traverse City, Mich.). With appropriate scaling, the two curves can be overlaid almost exactly.

Draexlmaier Automotive of America in Duncan, S.C., is using a Temp-Tek nozzle sensor as an in-process quality check to detect viscosity changes that would occur if there were a change in the blend ratio of long-glass compound and unreinforced pellets being fed to a 4000-ton press. Otherwise, parts could be produced with insufficient strength but no visible signs of the change in reinforcement loading. Dennis Quinby, injection molding process engineering supervisor, says the Temp-Tek sensor “works well and is very cost-effective for what we’re trying to do.” He is also exploring the potential of the sensor to indicate screw wear through a change in the thermal profile.

Another molder, which did not wish to be identified, has been using 16 Temp-Tek sensors in extensive development work. It uses the sensors in the nozzle, mold vents, and hot-runner manifold on the same machine. And, like other molders interviewed for this article, the thermal sensor is being used together with cavity-pressure sensors. A senior molding manager at the company, who has 30 years of experience and is a certified expert in Scientific Molding, says the combined use of different sensors is enabling advances in process monitoring: “We’re doing things no one else has done,” he says, though he could not go into much detail. He did say, however, that the Temp-Tek sensors provided an unprecedented capability for “dynamic” thermal monitoring: “We can see things happen over every phase of the cycle.”

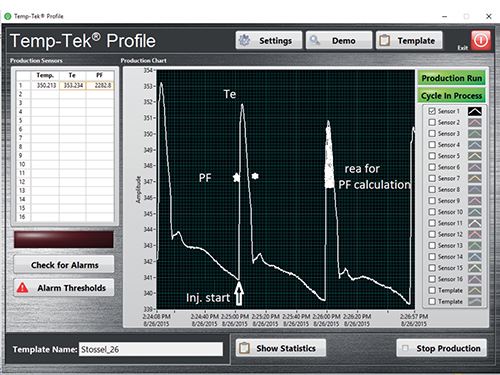

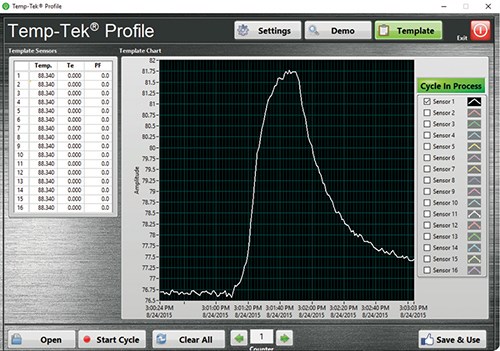

Durina says the sensor can be used to detect changes in the process caused by screw/barrel wear or batch-to-batch variations in resin quality or moisture content. Durina’s new PC software makes it easy to use the shape of the total-energy curve and the area under the curve as QC tools. The software can run on a standard laptop. It takes signals from a module into which up to 16 sensors can be plugged, along with a 24V signal from the press at the start of injection. For startup of a new mold, the user would run until a good shot is produced consistently, and then hit a button marked “Create Template.” This stores a sensor output curve for a good shot based on 75 readings/sec. (Higher sample rates can be provided as an option.)

After running several good shots, the user can go to the new software’s Statistics page and examine the minimum, maximum, and average values for two key parameters—the maximum point in the cycle curve (Te) and the Power Factor (Pf), or area under the curve. The user can then set alarm limits for those factors, but knowing where those limits should be set requires empirical data on how much variation in those values will produce a bad shot. Durina says the Temp-Tek output curves can show the instantaneous results on total energy input of changes in backpressure, barrel temperature, screw speed, injection velocity, and melt decompression.

In complex, multicavity molds, Durina recommends putting a sensor in both the nozzle and in the last cavity to fill, which can be established via short shots. Sensor output gives an indication of melt density in the cavity, which Durina says is “the best variable that can be used to determine injection-pressure transfer from pack to hold.”

He also notes that an advantage of Temp-Tek sensors over conventional in-mold sensors is that they can be placed anywhere in the tool—at the parting line or even inside a slide or a pin. A lower-cost solution, uniquely available with Temp-Tek sensors, is that they can be located in the vents with little or no mold modification. There, they can measure the temperature of the vent gases on each shot as a proxy for melt temperature.

Md Plastics has sold more than 20 sensors so far to a small handful of molders. Nozzle sensors cost about $379 apiece, and in-mold sensors under $300. Modules that send data to a PC come with capacity to plug in up to 16 sensors. Price is under $7000 for the module plus one nozzle sensor and monitoring software.

Md Plastics also recently signed its first license with a machinery OEM to integrate its Temp-Tek monitoring software with the injection press controls. PASL Windtech (P) Ltd. in Ahmedabad, India, recently introduced its HM Series of servo toggle and hydromechanical presses from 160 to 880 tons. According to managing director Abhishek Javeri, the Temp-Tek sensor is “something that has not been offered before in the ability to measure actual melt temperature at the nozzle. We hope to offer customers the ability to develop a thermal template for a good part and then compare each subsequent part to know if it is good or bad. We hope to offer the nozzle sensor and control software as a standard feature across our machine range.”

Durina notes that the Temp-Tek sensor can also be used in other processes: In blow molding, it could be placed in the mold or inside the parison to measure the air temperature there. In extrusion, it could be placed in the melt stream or in the die; it could also measure the air temperature inside a blown film bubble, providing information not usually available. I thermoforming, the sensor could be mounted between the sheet and the mold.

Related Content

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More