News in Hot Runners & Tooling At Fakuma 2017 Show

Highlights included some unusual solutions to common problems, slim nozzles for close spacing, and controls with lots of zones, as well as a handful of new cost- and space-saving standard mold components

Just a year after the massive K show, Fakuma 2017 in Friedrichshafen, Germany, was a bit light on major machinery developments, most of which have been covered in the last few issues. But in hot runners and mold components, there was plenty of news, including some genuinely novel solutions to common problems.

TWO UNIQUE DESIGNS

One of the most unusual hot-runner designs at Fakuma was a developmental project from Milacron, Cincinnati (Mold-Masters / Milacron). It is exploring a new Mold-Masters concept called “No-Gate” hotrunner technology that is intended to solve a problem in molding round parts with a hole in the center, such as sport caps, flip-top closures, and gears. Such parts are necessarily gated off-center, which creates potential issues of loss of concentricity in response to injection pressure from one point on the circular base of the part.

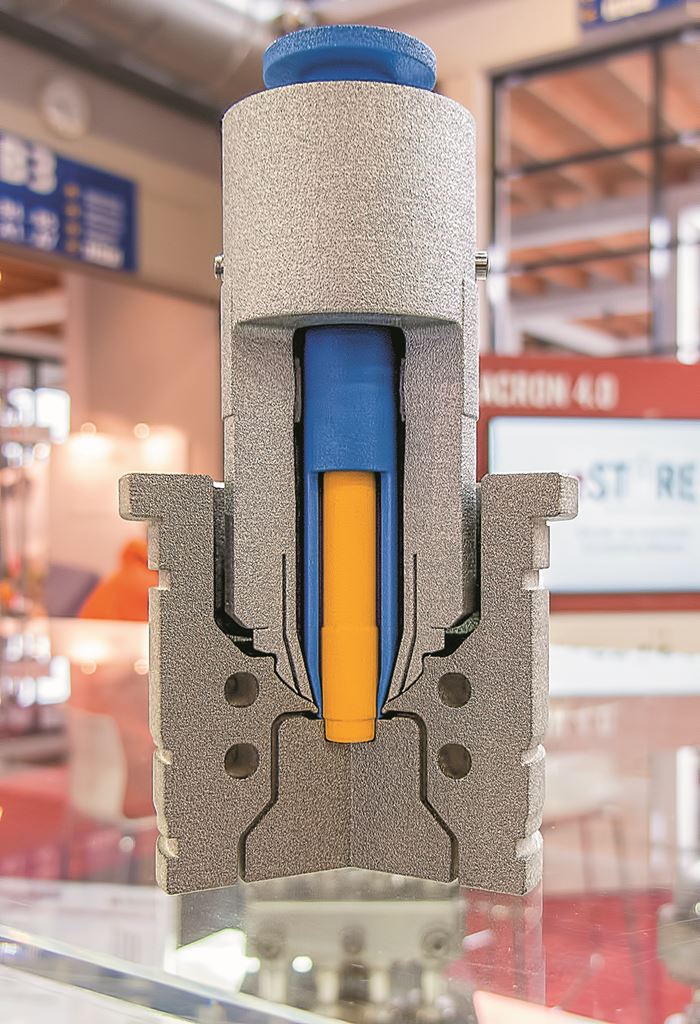

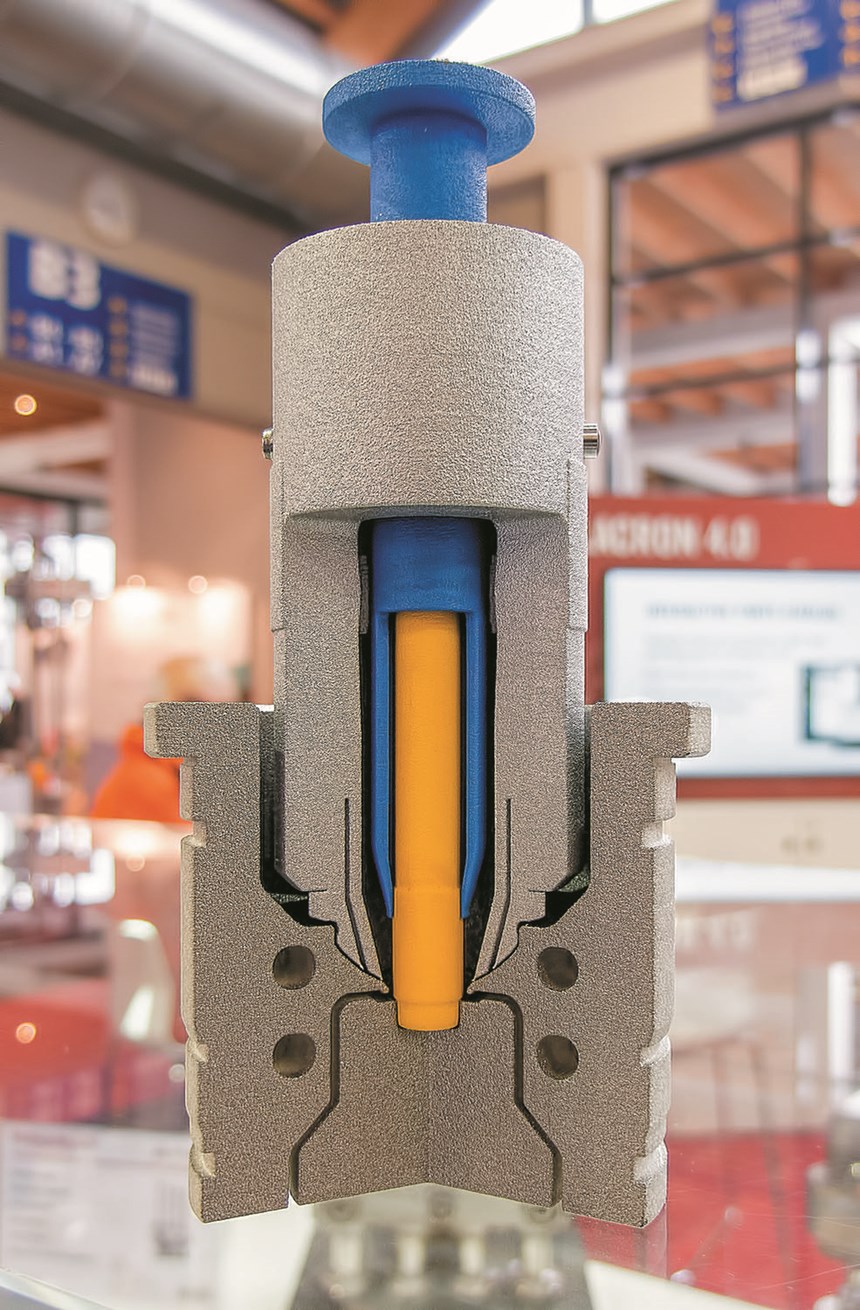

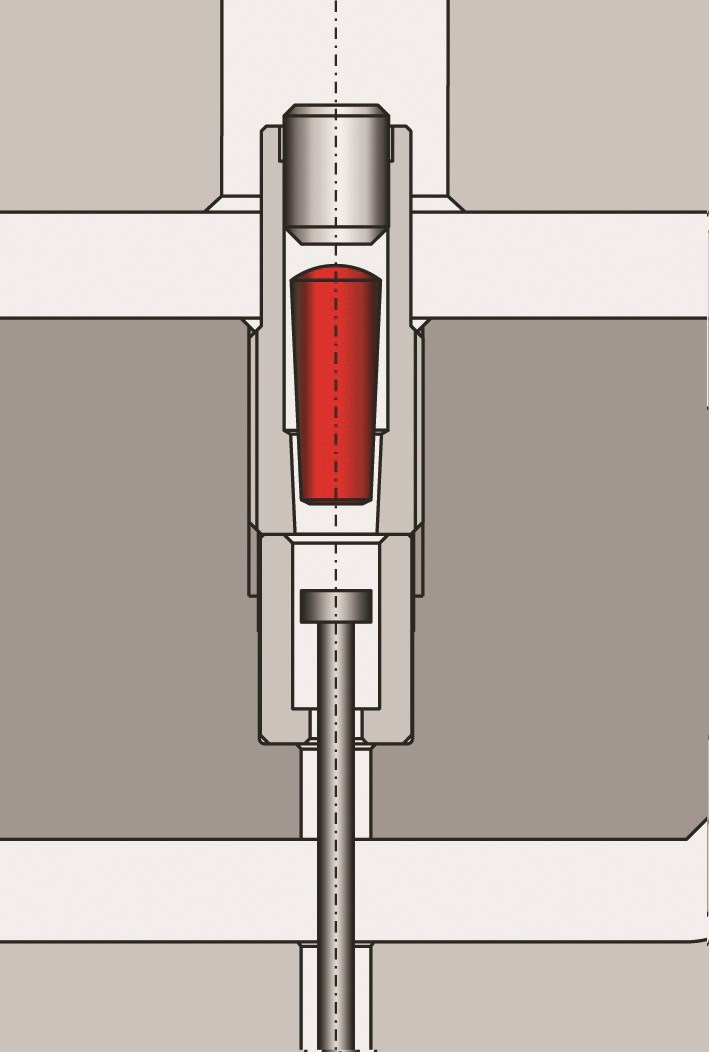

The No-Gate concept offers various versions that depend on the part details, particularly the function of the hole in the center. One version was shown in the conceptual model exhibited at Fakuma (see photos), which, in a sense, reverses the operating principle of a normal valve gate. The nozzle contains a reciprocating sleeve surrounding the stationary core pin that forms the hole in the center of the part. The sleeve shuts off against the core pin in the closed position, and lifts up to open an annular gate that allows melt to flow all around the core pin at once, providing uniform melt pressure around 360°.

Novel solution for gating a round part with a hole in the center is like a valve gate with a stationary pin.

Another unique hot-runner design at Fakuma was the Flat Die Unit (FDU) from Haidlmair of Austria (North American office in Concord, Ont.). First introduced at the K 2016 show, the FDU is an open nozzle in the shape of an elongated rectangle instead of a round cylinder, with an angled tip insert that resembles an extrusion flat die—hence the name. Designed for medium to large parts, it leaves a witness line rather than a circular mark. The FDU is said to provide the same or faster fill rate versus a conventional nozzle, but with lower shear and pressure drop. The original model has a 58-mm long gate; a brandnew version is less than half as large.

Haidlmair cites two commercial applications as examples of the FDU’s advantages. A dishwasher base carrier of talc-filled PP reportedly has run 100,000 parts with a 12% cycle-time reduction compared with conventional hot-runner molds that Haidlmair has built for this application in the past. Pressure drop was reduced by 22%. Another application is an HDPE shipping container that molds 17% faster with 25% shorter injection time, 18% lower injection pressure, and a more stable process to boot. The FDU is currently optimized forpolyolefins, but soon it will be optimized for other resins as well.

MORE NEW NOZZLES & CONTROLS

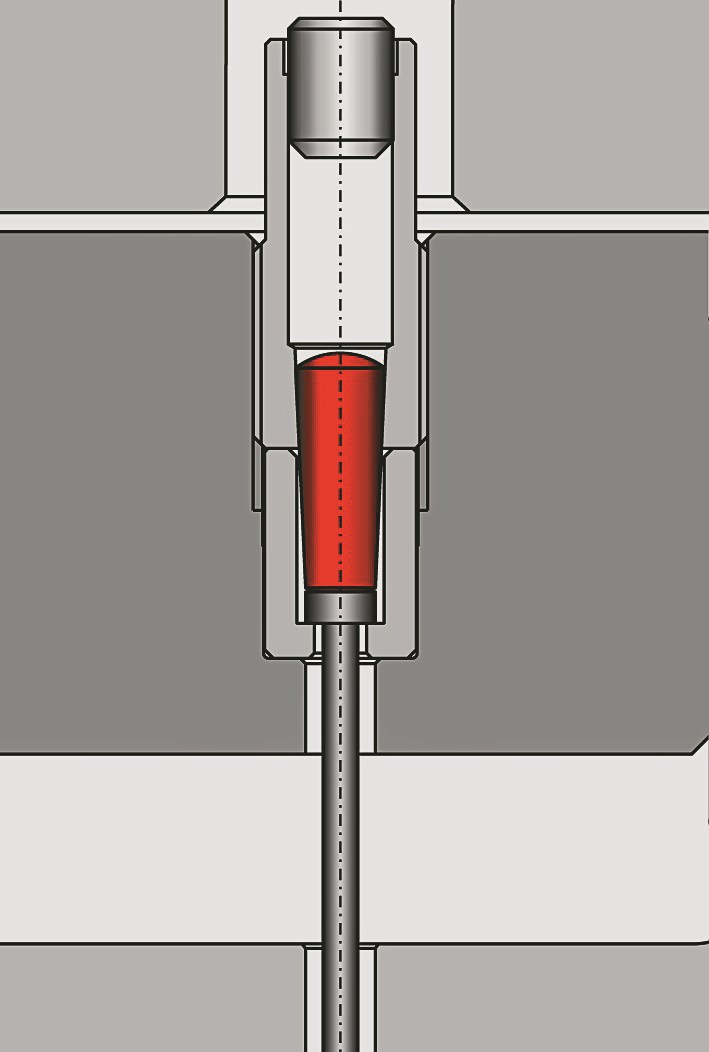

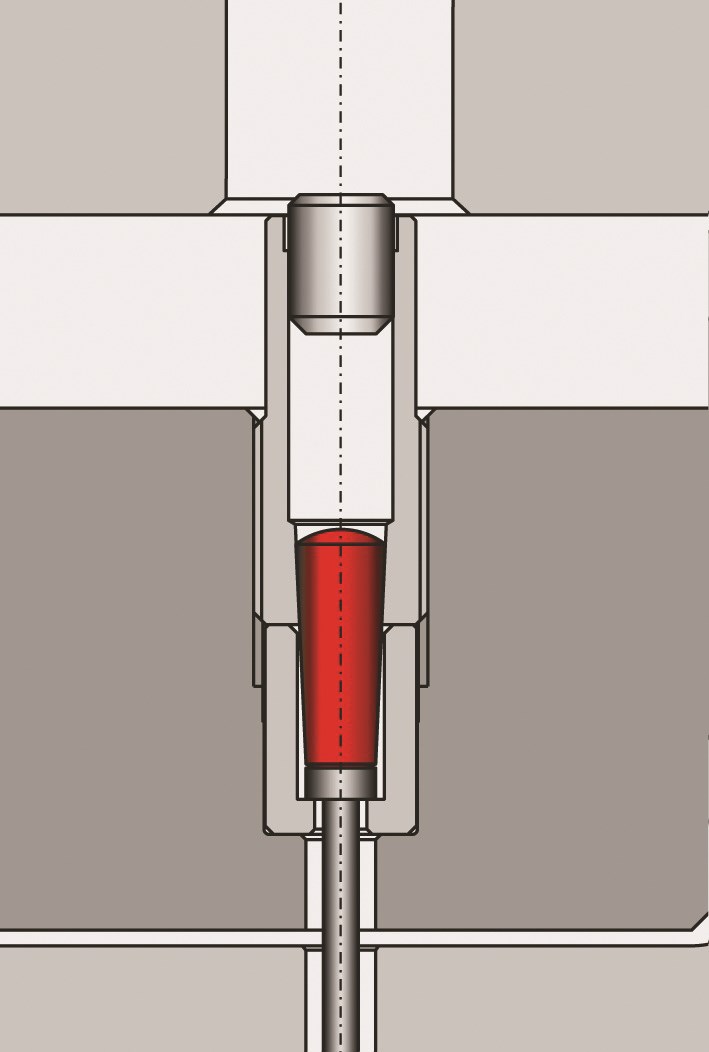

Several new products were shown by Ewikon Molding Technologies, Inc. (U.S. office in Rockford, Ill.). The most unusual was an “overload safety device” for valve-gate systems with synchronous plate actuation.

In such systems, blockage of one gate results in concentrated pressure on that one pin, potentially causing it to break. Ewikon’s solution places a conical “safety pin” (shaped somewhat like a wine cork) in a matching guide.

When the valve-pin movement is blocked and the defined maximum permissible pressure load is reached, the safety pin is pushed out of the guide, thereby uncoupling the valve pin from the movement of the synchronous plate and leaving the pin undamaged.

The safety pin can be restored to its normal position. This patent-pending technology is available as an option for all new molds with valve gates and synchronous plate actuation and a valve-pin diam. of 2 mm.

Unique rectangular nozzle provides faster filling with lower shear and pressure than a conventional nozzle.

In addition, Ewikon brought out the new L2X-Mikro system designed for shot weights down to 0.05 g on small machines, including tabletop units like those from Babyplast and Boy Machines Inc. The L2X-Mikro is available in standard layouts of two, four, or six nozzles, and the compact manifold dimensions (61 by 48 mm) reportedly fit the most commonly used mold sizes for small molding machines. The nozzles have an O.D. of only 10 mm and a 3-mm flow channel. They screw into the manifold to prevent leaks.

The L2X is based on the Mikron manifold technology introduced at Fakuma 2015 and shown at K 2016. In that design, each manifold drop feeds a secondary drop with four nozzles that constitute one control zone whose heat is supplied by the primary manifold one level above. That system is aimed at polyolefins and commodity resins, but the new L2X version has individually direct-heated nozzle tips, suiting it to engineering resins.

Also new is Ewikon’s HPS III-MHR111 multi-tip nozzle for direct side gating of long, tube-shaped parts such as medical syringes or pipettes. The round nozzle body has been slimmed 15% from the standard version. Extended tip inserts allow more space between the nozzle body and the cavities to provide room for cooling and venting.

The heated nozzle body is joined to a nozzle retainer that’s available in different lengths to allow different immersion depths of the nozzle to accommodate very long parts. The nozzle comes with two, four, or eight tips. Standard tip angle is 90° but 60° is also available. Tip inserts are exchangeable on the machine from the parting line.

The company also offers a new nozzle coating that protects against chemical corrosion; it will become standard next year. New controls from Ewikon include the DPE4 valve-gate controller, the company’s first with an electric stepper motor. It offers three valve positions and can be controlled from a handheld tablet.

Ewikon’s new DPT24 temperature controller offers 12, 18, or 24 zones, but multiple units can be ganged together. It has a touchscreen interface instead of the LEDs in former units and accepts gesture commands like a smartphone or tablet.

Questions about hot runners? Visit the Hot Runners Zone.

Hasco America Inc. (U.S. office in Fletcher, N.C.) is replacing its older multi-zone hot-runner temperature controllers with new H1252 units having six or 12 zones. Described as “attractively priced,” they offer two numerical LED displays per zone of set and actual values.

They offer 3600 W/16 A per zone and are suited to temperatures up to 600 C/1112 F. Soft-start and boost functions are supplied, along with monitoring of heaters and thermocouples. Fuses for heating zones are replaceable without opening the housing.

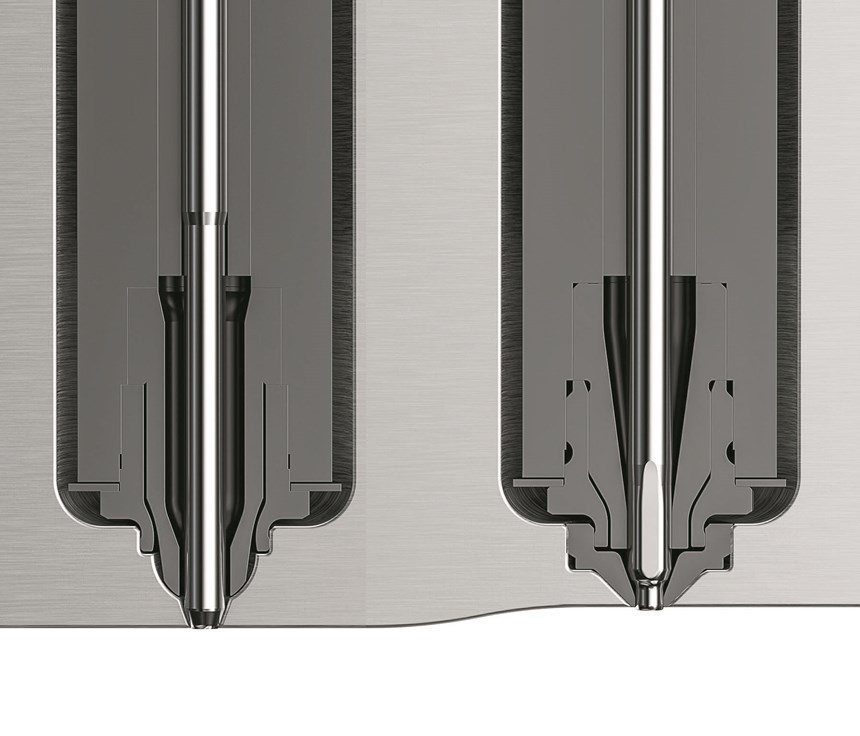

As reported in September’s Keeping Up section, HRSflow (U.S. office in Byron Center, Mich.) introduced new compact, screw-in nozzles for small, delicate parts. In addition, the company showed off the new HPgate, a valve-gate solution that is said to simplify work for the moldmaker. The key is a hard metal insert, supplied with a conical-cylindrical gate, and which is screwed into the mold. This saves the moldmaker the time-consuming and complex machining of the standard cylindrical gate. The high hardness of the insert allows a softer metal to be used for the mold base. And if the insert becomes worn, it can be easily and inexpensively replaced.

An additional advantage comes from the special needle geometry, in which the conical contact surface allows better thermal control of the needle, while the precisely aligned cylindrical needle closure provides sealing. HRSflow says the conventional conical gate configuration leaves a typical plastic layer at the gate point when the valve closes. When the mold opens, this layer is torn off the part, possibly leading to flash formation.

Obtaining good detachment and avoiding flash reportedly often requires fine adjustment of process conditions. But the HPgate eliminates the plastic residue layer because of the cylindrical needle closure, thereby reducing the time required to optimize the process and produce good parts.

Although known primarily for large automotive parts, HRSflow also showed off its capabilities for hot-runner molding of food and cosmetic packaging. It has configured a 96-cavity hot half with M-series thermal-gate nozzles for beverage-bottle caps. In fact, Corvaglia, a Swiss molder of caps for PET bottles, uses a HRSflow hot side with 96 cavities to mold HDPE caps for still water weighing only 0.82 g in just 2.15 sec. The nozzles are HRSflow’s MTF (Multicavity Fast Line) thermal-gate types.

Husky Injection Molding Systems Ltd., Bolton, Ont., had several new developments at the show. One was the Ultra Side Gate Inline hot runner module for direct gating of long, thin, closely spaced parts. It has up to four nozzles arranged in rows instead of the original circular pattern.

Husky also recently announced that it had expanded capacity for its Ultra Helix servo-controlled valve-gate nozzles (4000 sold), which will allow the company to explore their use with a wider range of “more challenging” materials.

New control systems on display included the Altanium Delta5, which replaces the Delta3 version. Like the earlier model, the Delta5 controls 128 temperature zones plus one servo axis. What’s new is the larger 15-in. display screen (up from 10 in.), which now is mounted separately from the PC control unit. A similar display upgrade distinguishes the new Altanium Matrix5 controller, with 22-in. screen, 255 heat zones, and one servo axis. By the end of the year, Husky plans to launch the Altanium Neo5 (replacing the Neo2) with 48 heat zones. There’s also a new Altanium VGS valve-gate sequencer (available now) for pneumatically and hydraulically actuated systems. All these new controllers will be shown at NPE 2018 in Orlando, Fla.

PSG, part of Meusburger US, Inc. Standard Molds showed off its newest version of the profiTEMP+ controller, originally introduced at K 2016. (PSG is represented here by Thermal-Tech Systems, W. Chicago, Ill. In addition to the original desktop model with up to 48 zones, there is now a free-standing tower version for up to 120 zones; linking up a second tower can control up to 192 zones.

New hot-runner control modules offer up to 336 zones.

S.I.S.E. of France (SISE Plastics Control Systems, Inc.) brought a new model of the MV3 controller to Fakuma (first introduced with 96 zones at K 2016). Now available are either 146 or a whopping 336 zones for caps/closures and other packaging. A 48-zone version will be available next. These free-standing units have touchscreens and can be integrated with injection-machine controllers via the newly incorporated OPC-UA communications protocol. The hot-runner control can be mirrored on the press control and can transmit alarms to the press display as well. New control features include a soft-start function and automatic recognition that heater and thermocouple connections are not reversed.

THERMOPLAY SPA, part of the Barnes Group (represented here by ALBA Enterprises, Rancho Cucamonga, Calif.), is now offering the F 011 mini valve-gate nozzle (introduced at K 2016) with tips that are replaceable while the mold is in the press. These nozzles have 10.5-mm diam. and 17-mm minimum pitch.

Related Content

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreRead Next

Hot Runners & 3D-Printed Molds Headlined at K Show

Automotive was a key focus for hot-runner developments. 3D-printed plastic prototype tools were another highlight.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More