News in Injection Molding Control & Monitoring from NPE2012

There were also several interesting developments in injection molding control and monitoring systems at this past April’s NPE2012 exhibition in Orlando, Fla.

Besides a host of new machines, hot runners, and robots at this past April’s NPE2012 exhibition in Orlando, Fla. (reviewed in June, July, and this issue, respectively), there were also several interesting developments in injection molding control and monitoring systems. These include what’s said to be a brand-new approach to melt-temperature sensing and process control, plus new hardware and software for cavity-pressure and temperature sensing, process optimization, position sensing, and energy monitoring.

NEW APPROACH TO PROCESS CONTROL

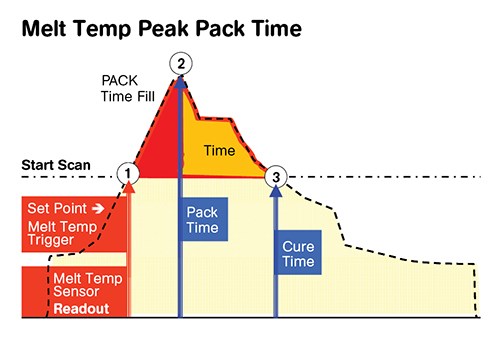

Inventor Fred Buja and Windspeed, Inc., St. Thomas, Ont. (windspeedinc.com), have come up with a new method of melt-temperature measurement and process control. His patented thermoelastic sensor consists of a spherical bead of metals that expands and contracts under the influence of both melt temperature and pressure. This thermoelastic strain is converted to a temperature reading. The sensor, which is only 1 mm diam., can be located in the nozzle for melt-temperature monitoring, or in the cavity for process control, or even in the vents as a low-cost solution. The sensor face is mounted slightly recessed from the melt channel and does not project into the melt stream. It is not influenced by the temperature of the steel surrounding it, Buja notes. Response is said to be very fast—around 25 millisec.

According to Buja, the key principles are that a temperature increase causes a volume increase in the sensor bead, while a pressure increase on the bead decreases its volume, which raises its internal temperature (pressure x volume = temperature). The sensor is calibrated to a zero reading at 0°C and 1 bar pressure.

According to Michael Durina, president of MD Plastics (mdplastics.com), which markets the new sensor for Windspeed, the new sensor offers several advantages to molders. One is that very few

molders currently measure their melt temperature, owing to the limitations of previous techniques (such as manually sticking a pyrometer into a purged sample of melt). Now they can get an accurate picture of what their plasticating process is doing to the melt.

Second, Windspeed’s 4S TeMp monitor provides a readout of the area under the temperature curve for each shot. This area can be used to distinguish good from bad shots and can be used for startup to verify that your process is the same as previously run with that mold, even on another machine. Durina notes that the sensor costs $190, much less than piezoelectric sensors used for cavity-pressure control. Windspeed and MD Plastics offer both individual sensors and a, $8500 package that includes the monitor and five sensors. The four-channel monitor can read four sensors in different machine nozzles or cavities of a mold. (Note: Buja says it can also be used for extrusion.) As a low-cost introduction to the technology, Windspeed is offering to retrofit a molder’s existing nozzle with one sensor and to insert three more sensors into vents in a mold, so no tool modification is necessary.

MORE NEW SENSORS & CONTROLS

Other news includes an addition to the Temposonics E-Series of economical magnetostrictive position sensors from MTS Systems Corp. (mtssensors.com). The EL model has a low-profile aluminum housing, reducing the overall height of the sensor.

Priamus System Technologies (priamus.com) has redesigned its cavity-temperature sensors with a hardened sensor front to resist abrasion from fillers or additives in plastic compounds. (For explanation of the uses of cavity-temperature monitoring, see the feature article in May.)

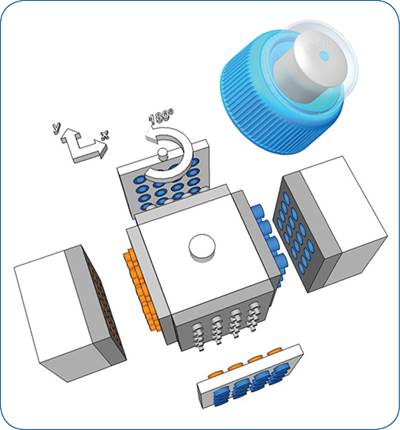

Priamus also introduced what it calls “a completely new connection concept” for in-cavity pressure and temperature sensors. This addresses molders’ chronic difficulties with such sensors—difficulty of plugging in two-pin connectors and inadequate shielding of some cables on the market. Priamus now offers individual sensor cables designed for easy and “foolproof” insertion into a multi-channel connecting box. The box can be mounted directly on the mold or in a milled slot to save space. Cable management is greatly simplified, as only one cable is required for an eight-channel connection to Priamus’s new BlueLine all-digital amplifiers.

As reported in our March preview, the main attraction at Priamus’s booth was its BlueLine hardware and new FillControl software. The latter uses in-cavity sensor inputs to monitor melt viscosity in the mold and detect any changes caused by the material or process. It does this by monitoring and controlling shear rate (by adjusting injection speed profile) and shear stress (by adjusting barrel and hot-runner temperatures). It also provides uniform packing in the cavity by adjusting the hold-pressure profile. And it maintains consistent shrinkage by adjusting mold-temperature control units. All this is in addition to ensuring uniform filling by adjusting hot-runner temperatures at each nozzle.

In March, we previewed several sensor and controls developments from Kistler Instrument Corp. (kistler.com). In addition, Kistler announced at the show that it is now offering the STASA QC Operating Point Navigator, developed by the German software company STASA (stasa.de). This process optimization software automatically determines which process variables affect the quality of a specific part, and by how much, through systematic design of experiments (DOE). This determines an optimum process window for meeting quality needs with a stable process.

ENERGY MONITORING

NPE was the U.S. debut of the Shotscope NX Energy module (first shown at K 2010) from Husky Injection Molding Systems Ltd., Bolton, Ont. (husky.ca). This module provides enhanced energy-monitoring capabilities throughout a plant. As part of the Shotscope process and production monitoring system, it can monitor kWh/kg energy consumption for individual presses, chillers, or other auxiliary equipment, up to complete molding cells.

Related Content

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreRead Next

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read MoreAchieve Process Transparency with In-Mold Cavity Sensors

In plastic injection molding, the primary objective is to manufacture dimensionally and structurally consistent parts, independent of the molding machine being used.

Read More