Not Running, But Still Pushing Technology Envelope in Film Extrusion

W&H sees options in retrofitting game-changing quick-switch technology.

Used to be, you’d see about as many running blown-film lines at NPEs as you would at the K Show. But while many builders of blown-film lines still operate systems at the giant triennial show in Dusseldorf—some more than one—most have scaled things back where NPEs are concerned, citing the cost of resin and power, as well as the “impracticality” of how to dispose of finished rolls.

But that’s not to say there aren’t some interesting things to see and talk about in Orlando. In the case of Windmoeller & Hoelscher Corp., (Booth W6663), retrofits will be a big theme. The company has made its revolutionary TurboClean technology automation module retrofittable to some existing W&H lines. The TurboClean system purges resin from all extruders and gravimetric hoppers simultaneously, dramatically decreasing the time required to change materials. It was introduced at an open house W&H held at its Lengerich, Germany headquarters in mid-2015, then officially unveiled at K 2015, but was available only on new W&H Varex II systems.

But now, existing W&H Varex II and Varex I lines built in or after 2010 can be retrofitted with the module, allowing blown film processors to benefit from significant cost savings via faster job changes. With TurboClean, material changes are almost completely automated. Operators no longer need to manually purge resin one extruder at a time. Instead, the work steps are automated and run simultaneously, requiring the operator only to change the suction wand from one resin port to the next. This system is said to reduce the time it takes between product changeovers from 30 min to an astounding two min.

“W&H commercialized the industry’s first automatic gauge-control technology in the late 1980s with the Optifil P system, and the TurboClean is yet another example of our efforts to take scrap out of the blown-film process,” states Andrew Wheeler, president of W&H Corp. Some film structures contain not only multiple layers, but each layer can be comprised of a half dozen or more different material components. “Smaller companies in particular—film processors with three to five lines—will get a very quick return on investment on TurboClean,” Wheeler states. “If they do shorter runs and make multiple changes a day, TurboClean will pay off very quickly.” But the technology is also suited to larger-sized processors with much longer run times. “These film processors are concerned about pounds, pounds, pounds,” says Wheeler. “They might do one or two changes a day. But by compressing the time between changes, they are freeing up machine time and might be able to fit in another order.”

Wheeler reports that W&H has lines equipped with TurboClean installed (or on order) in North America.

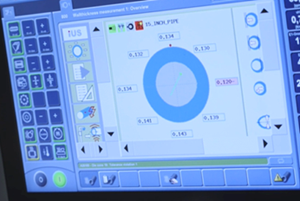

Wheeler also notes more processors investigating mid-size Machine Direction Orientation, improving properties by adding 5-10% stretch post-processing. On the matter of Industry 4.0—or Packaging 4.0, in W&H’s parlance—Wheeler notes Filmex II cast film lines are being furnished with its recently introduced Film Performance Monitor (FPM). “We’ve been pushing the idea of networking machinery for a long time in extrusion, and we’re seeing more customers gearing up for it. FPM integrates data from the extrusion line with downstream converting equipment, allowing these two previously discrete operations to be networked to improve quality and make the entire production process seamless and traceable.”

Related Content

Fully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)