Now LDS Electronic Circuitry Is Colorable

Laser direct structuring (LDS) is a powerful technology for adding electrical circuit paths to plastics electronic products such as mobile phone and notebook antennas or molded interconnect devices (MIDs). But up to now, LDS-ready plastics were limited to black.

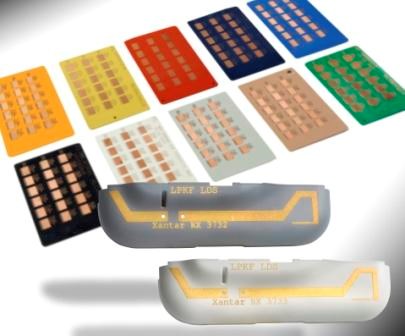

Laser direct structuring (LDS) is a powerful technology for adding electrical circuit paths to plastics electronic products such as mobile phone and notebook antennas or molded interconnect devices (MIDs). But up to now, LDS-ready plastics were limited to black. Now two suppliers have come up with customcolorable materials for LDS. SABIC Innovative Plastics, Pittsfield, Mass., was the first, with its LNP Thermocomp NX11302 (photo), a specialty PC/ABS for applications like LEDs and connectors. It was soon followed by two grades from Mitsubishi Engineering Plastics (MEP America, N.Y.C.). It brought out Xantar LDS 3723 PC/ABS for mobile-phone housings and other telecom devices, as well as Xantar LDS 3733 PC for antennas.

LDS is made possible by formulation technology from LPKF Laser & Electronics AG in Germany (U.S. office in Tualatin, Ore.). Its approach involves compounding a special additive into the plastic. Then, specialized lasers are used to scribe the circuit layout onto the plastic part. The laser light activates the additive (an organic metal complex) so that it will accept electroplated copper and also roughens the plastic surface to help the plating adhere.

Related Content

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

Prices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.